2777

Technical Committee 212 /

Comité technique 212

respectively. One of the failure modes of a tested specimen is

also shown in Figure 4.

Table 1. Dimension of the FRP tube specimen

Classification

Number of

specimen

Thickness

(mm)

Width

(mm)

3

2.8

3

4.2

Split disk

test

3

5.6

30

3

2.8

3

4.2

Filament

winding

FRP Compressive

test

3

5.6

L= 600

D

=

300

Tensile test

of inner arc

3

3.9

25.3

Tensile test

of outer arc

3

3.7

28.5

Pultruded

FRP

Tensile test

of rib

3

3.1

24.7

Table 2. Test results

Classification

Thick

ness

(mm)

Failure

load

(kN)

Ultimate

Strength

(MPa)

Modulus of

elasticity

(MPa)

2.8

62.3

294.6

22.2

4.2

112.7

326.9

23.3

Split disk

test

5.6

157.7

318.8

22.6

2.8

254.9

194.1

N/A

4.2

507.4

258.2

N/A

Filament

winding

FRP Compressive

test

5.6

647.1

247.5

N/A

Tensile test

of inner arc

3.9

25.6

260.1

22.4

Tensile test

of outer arc

3.7

22.8

214.2

27.9

Pultruded

FRP

Tensile test

of rib

3.1

29.8

387.4

31.4

Figure 4 Failure mode.

The mechanical properties were determined from the

experiments conducted by changing the thickness. In the test,

three sets of tests with different thickness and each set consists

of three specimens are prepared. Specimens were taken from the

FRP tube and the properties were, then, calculated by averaging

the results obtained from the split-disk test, compression test,

and tensile test. From the tests result, it can be observed that the

mechanical properties for the FRP tube specimens were almost

similar. In the specimen preparation three different compressive

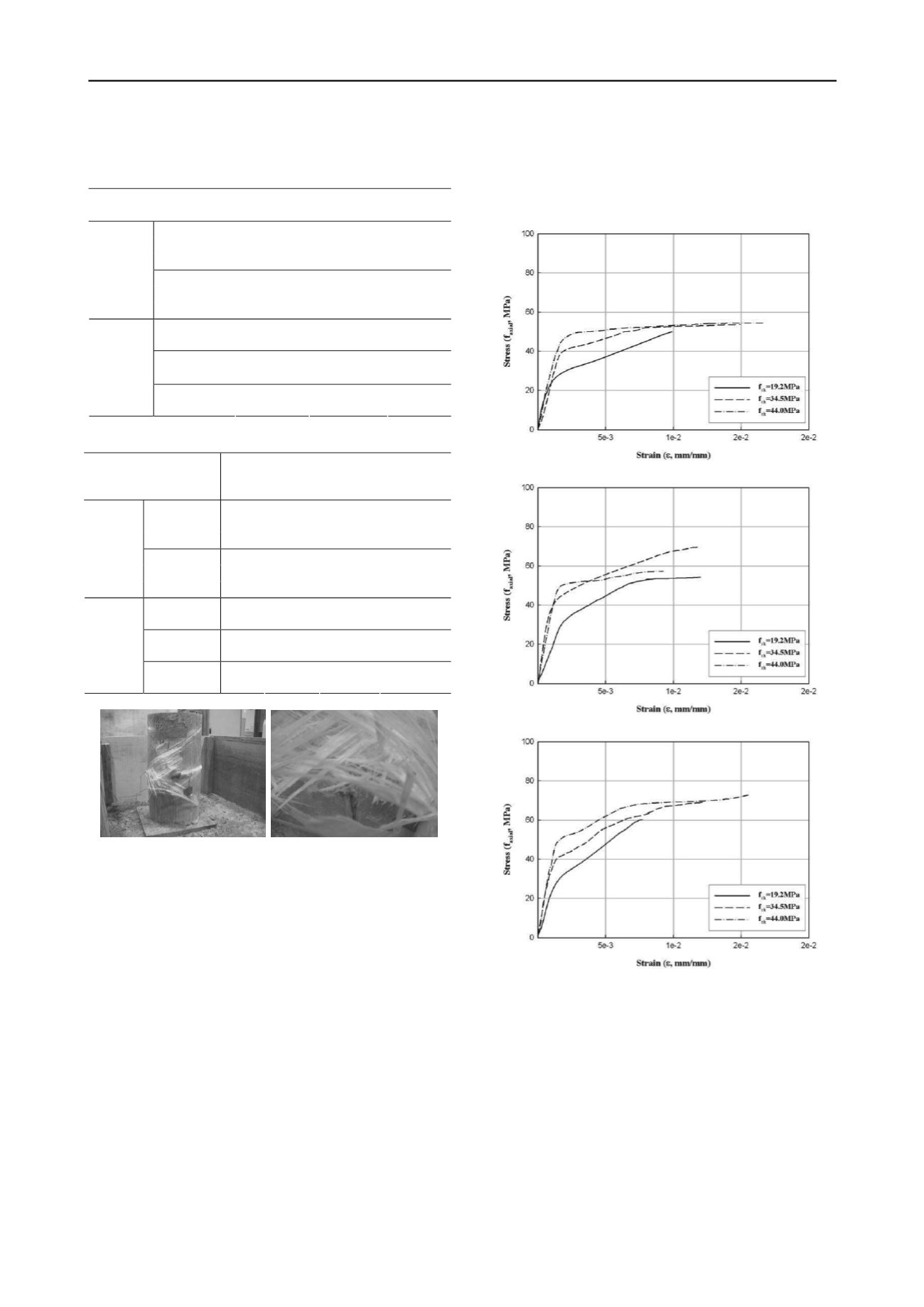

strengths of concrete, i. e., 19.2MPa, 34.5MPa, and 44.0MPa,

are used and the strength of concrete at the age of 28 days was

measured by tests.

2.2

Uniaxial Compression Tests of HCFFP

For estimating the compressive strength of HCFFP, uniaxial

compression tests on HCFFP members are conducted. It was

observed that the HCFFP specimens are finally failed after the

rupture of filament winding FRP. From the experiment, load

versus displacement at the upper part of a loading plate and the

load versus strain measured at the middle of the specimen are

obtained. The axial stress versus axial strain of confined

concrete specimen is shown in Figure 5.

It can be observed that the uniaxial compressive strength of

HCFFP is increased if the concrete strength and the thickness of

exterior filament winding FRP tube is increased. This tendency

is also similar to that of existing CFFP member used currently

in practice.

(a) 2.8mm FFRP

(b) 4.2mm FFRP

(c) 5.6mm FFRP

Figure 5 Axial stress-strain relationship of HCFFP specimen.

2.3

Flexural Test of HCFFP

For estimating the flexural strength of HCFFP, flexural tests on

HCFFP members are conducted. A total of 9 specimens, 3 sets

of test with 3 specimens for each set, were tested under four-

point bending loads as shown in Figure 6. In the test, specimens

with 3 different filament winding thicknesses, i.e., 2.8mm,

4.2mm, and 5.6mm, are used. It was observed that the HCFFP

specimens are finally failed after the rupture of filament

winding FRP. From the experiment, load versus displacement

measured at the middle and quarter points of span length of the

specimen is obtained.

It was observed that the moment estimated at failure of the

HCFFP specimens is almost similar regardless of the