2792

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

the pyramid is constructed of mass concrete. The footing is cast

inside a large excavation which is typically backfilled using the

excavated or imported material. In each case, the embedment

(H) to width (B) ratio is typically between 1 and 1.5.

1.2

Uplift resistance of footings

It is conventional to express the uplift capacity (Q

u

) of a footing

as:

Q = W

f

+ q

0

B

2

(1)

where

q

0

= N

uc

s

u

+γHN

us

(2)

The contributions from any base tension and backfill are

represented in Eq. 2 in the form of reverse bearing capacity

factors N

uc

and N

us

, respectively. The value of N

us

may be

quantified by a number of back analysed failure surfaces (e.g.

Murray and Geddes 1987) or through the use of design charts

derived from parametric numerical analysis (e.g. Merifield and

Sloan 2006).

Early physical testing at quasi static uplift rates investigated

the variation N

uc

with embedment ratio (H/B). There are

therefore many solutions available (e.g. Rao and Datta 2001).

However more recent centrifuge studies have shown that N

uc

is

also dependent on uplift rate (v

f

) (Lehane et al. 2008). Under

rapid loading (v

f

= 30mm/s) it was found that a single footing

founded on kaolin clay generated more than twice the capacity

in comparison to a slow uplift rate (v

f

= 0.3mm/s). The

difference in uplift capacities between v

f

= 0.1mm/s and v

f

=

30mm/s was proportional to the reduction of pore water

pressure below the footing base (Lehane et al. 2008). It was

proposed that the slow uplift rate allowed suction relief to occur

due to the gradual base/soil separation during uplift. This is

sufficient to relieve suctions and at approximately w/B≥6%

residual capacity was equivalent to a full breakaway condition.

Backfill

London clay

At very fast uplift rates (v

f

> 30mm/s) base separation does

not occur due to the full development of suctions that eventually

cause a reverse bearing failure to occur in the clay. This type of

failure results in a clay wedge remaining adhered to the footing

base post-pullout and capacity is determined by the undrained

shear strength of the clay (fully bonded).

2 FIELD TESTS

The aim of the field tests was to reduce the uncertainty

surrounding the in situ performance of transmission tower

footings. Reduced scale physical model tests conducted in a

geotechnical centrifuge demonstrated that during continuous

pullout out at increasing velocities that uplift capacity may be

significantly enhanced due to the development of suctions

occurring across the footing base. It was shown that uplift

capacity had a log linear relationship with the uplift velocity

(Lehane et al. 2008). The source of this contribution was the

formation of negative pore water pressures on the footing base.

However it is only at field scale that these effects can examined

and quantified in the context of realistic in situ soil conditions

and construction variabilities associated with full scale

footings..

To examine these issues a series of full scale tests were

commissioned at the Building Research Establishment's London

Clay test site at Chattenden, Kent (OS ref: TQ 75521 73987).

The field tests aimed to bridge understanding of the load-

displacement, load-rate and suction behaviour of soils from

small scale and numerical modelling to field scale. By using

different construction backfill materials to replicate as-built

construction practices, uplift rate and base interfaces across five

L4M tower type footings (Footings 1-5) that different uplift

mechanisms at full scale could be revealed.

2.1

Site layout

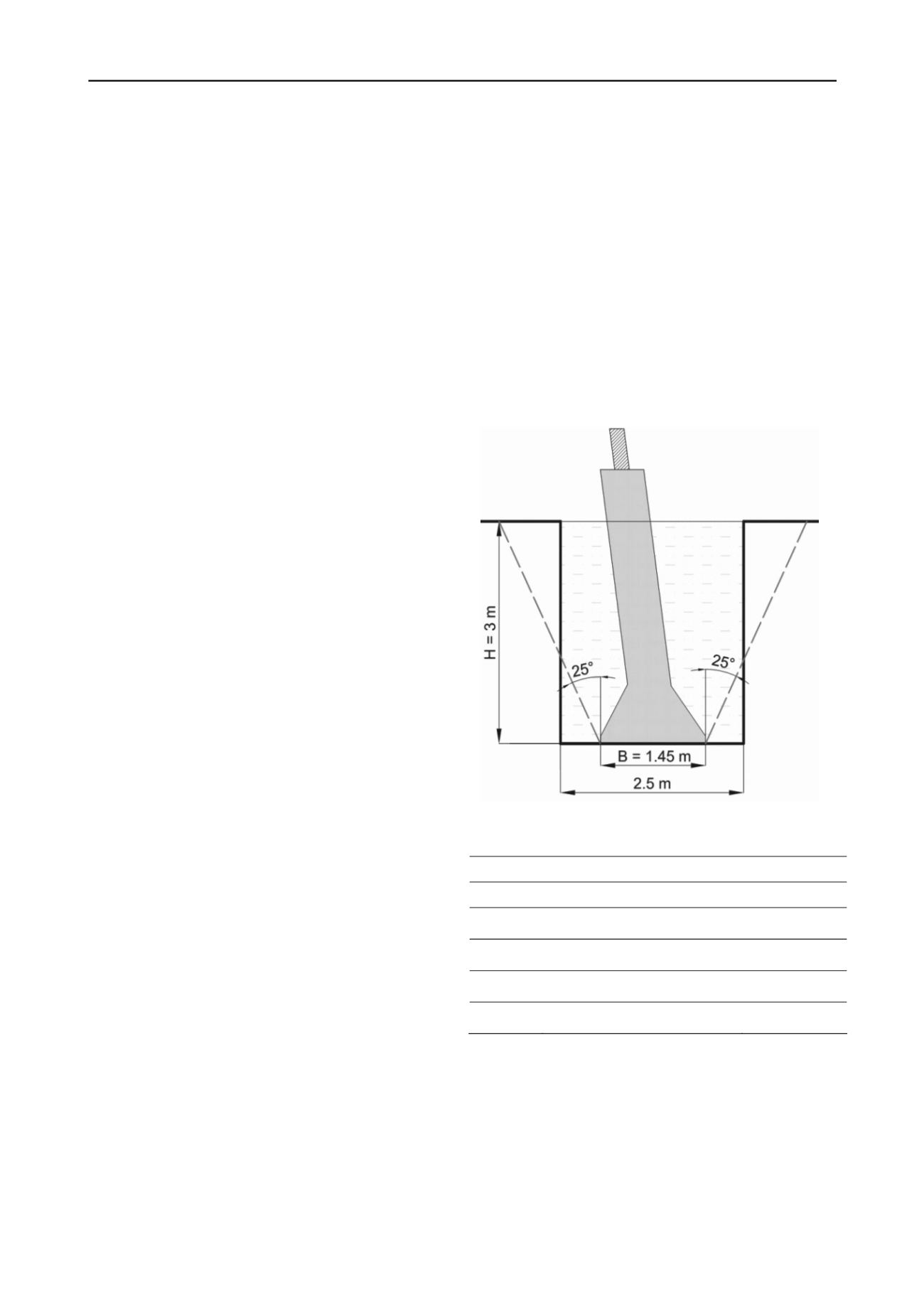

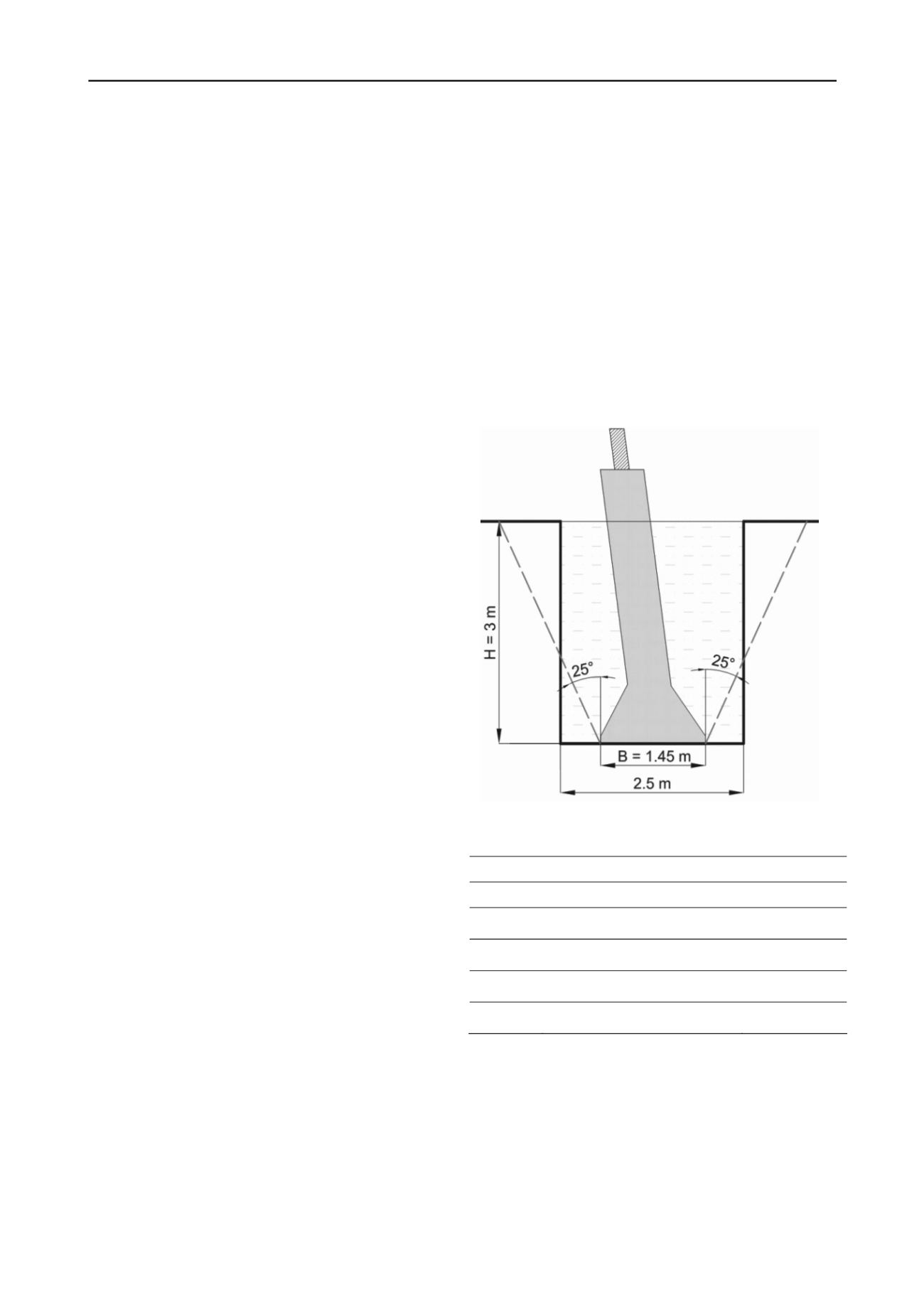

Five L4M footings were constructed at the Chattenden site in

August 2010. The footing geometry used is shown in Figure 1.

The footings were designed and constructed to TS 3.4.15 Issue

2 (National Grid 2004). The design uplift resistance (Q

des

) of the

footings using TS 3.4.15 was 420kN based on a 25

o

frustum

angle as s

u

>50 kN/m

3

on the founding plane (Butcher et al.

2009).

Each footing was installed with different base contact

conditions and backfill material (see Figure 1.). These variables

allowed the contribution of each resistance mechanism to be

isolated. Footings 1 and 2 were backfilled with tumbled and

compacted London clay – representing field/early construction

practices. Footings 3-4 used DoT Type 2 backfill - a coarse

granular material from recycled aggregate (Depart of Transport

2009). All footings were directly cast on the underlying clay

apart from Footing 3, which had a Type 2 free drainage layer.

Figure 1. L4M footing with a 25

o

frustum

Table 1. Footing specifications

Footing

Backfill

Base

1

Loose London clay

London clay

2

Dense London clay

London clay

3

Type 2

Type 2

4

Type 2

London clay

5

Type 2

London clay

2.2

Ground conditions

The Chattenden site has been used extensively for

foundation testing due to the presence of the deep and uniform

London clay strata (e.g. Butcher et al. 2009). The depth of the

London clay strata is ~30m and it was evident that during the

construction of the footings that the top 3m was heavily

weathered and fissured. The foundation tests were conducted

over a two week period in July 2012. The extremely wet

summer of 2012, particularly in the weeks prior to the field tests

resulted in the top layer of weathered clay became soft

(~s

u

=10kPa). It was also evident that the excavations backfilled