2588

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

3D (100% )

3D (67%)

2D_Block

2D_Strip (100%)

2D_Strip (67%)

2D_Strip (80%)

equivalent properties,

φ

block

, c

block

and E

block

derived based on

the semi-empirical relationships given by Madhav, 1996.

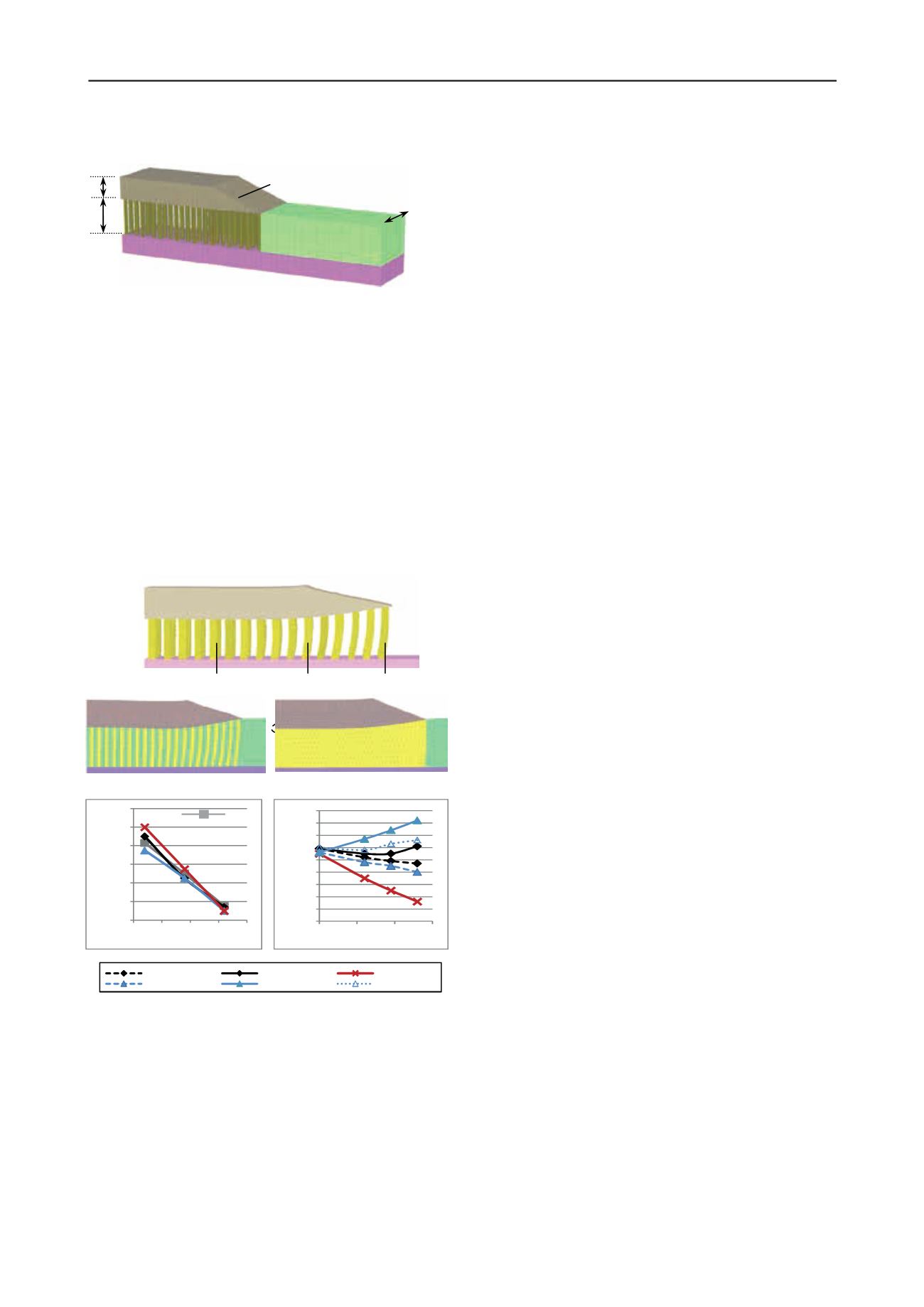

Figure 8. 3D FEA mesh

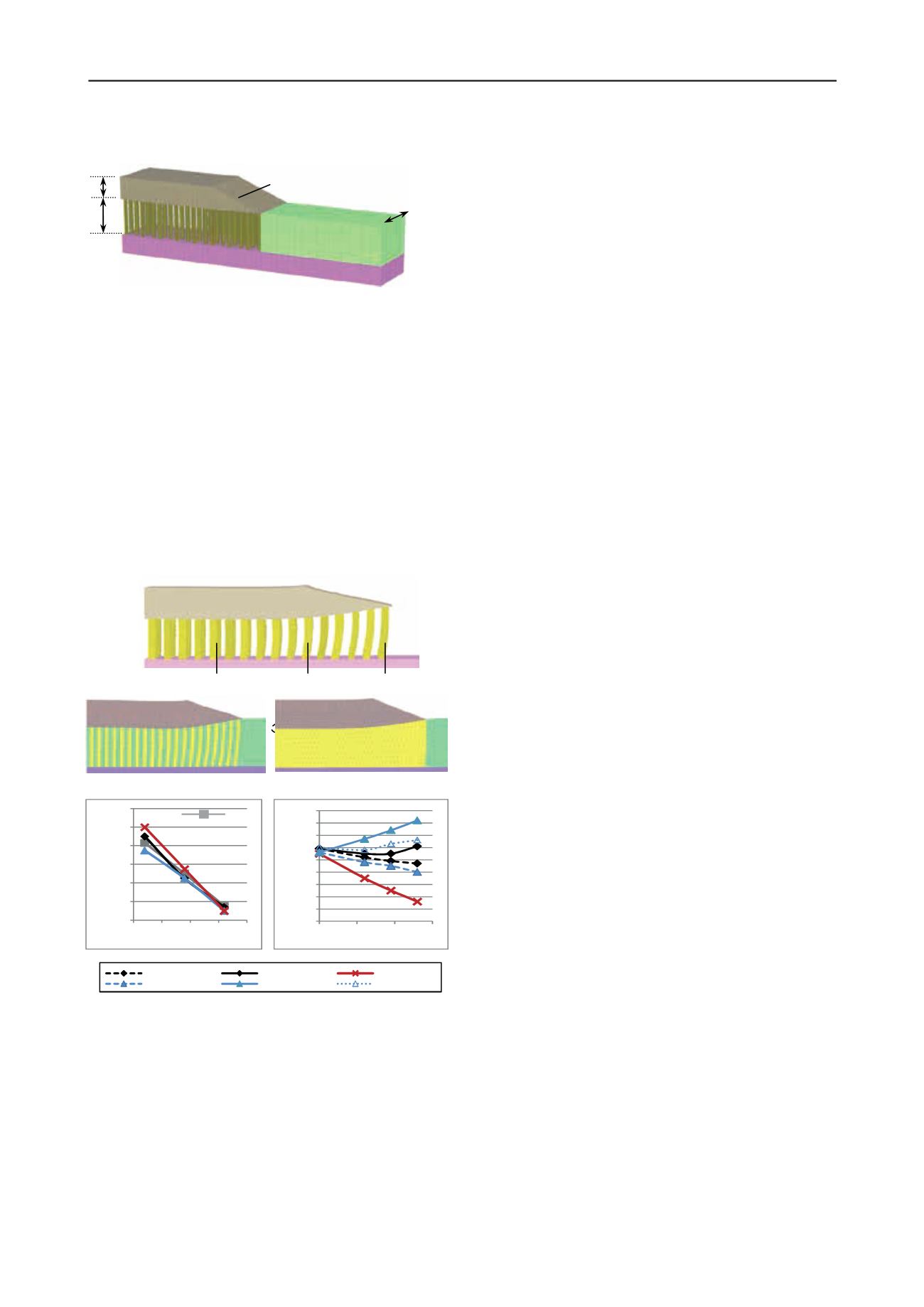

The baseline 3D model (Analysis 1) and the 2D strip model

(Analysis 3) show similar deformation mechanisms of the stone

columns, which can be broadly divided into three zones (see Fig

9a, 9b): Zone 1 away from the fill batter where columns

underwent vertical deformation by “bulging”; Zone 2 just

behind the crest of the fill batter where columns underwent both

vertical and horizontal deformation by “bulging” and “leaning”;

and Zone 3 beneath the fill batter where columns underwent

mainly leaning. This numerical prediction of the deformation

appears to be consistent with the results of the centrifuge model

test carried out by Stewart and Fahey (1994). The maximum

settlement of the embankment occurs in Zone 2 just before the

crest of the fill batter (more than that in Zone 1). This is

presumably due to the concurrence of bulging and leaning

deformation mechanisms of the stone columns. Conversely, the

columns in Zone 3 exhibit the maximum horizontal

displacement and are likely due to the prevailing leaning

deformation of the stone columns.

Figure 9. Comparison of FEA results

Figure 9c presents the deformation predicted by the

conventional 2D FEA using composite block material (Analysis

4). This method is unable to capture the bulging and leaning

deformation of the stone columns. The maximum settlement

occurs at the centre of the embankment (i.e. in Zone 1) as

opposed to in Zone 2 as predicted by the baseline 3D FEA and

the proposed 2D FEA using equivalent strips.

Figure 9d shows a plot of predicted settlements at points P

versus area replacement ratio

a

r

. All analyses give comparable

results, indicating that all the different FE methods are

commensurable in terms of settlement prediction under axially

symmetric load condition.

Figure 9e presents the predicted horizontal displacement at

point Q. The following points are drawn from the results:

•

hen original soil strengths are used for the interface

properties, the result of the 2D strip model (curve 1) compares

well with that of the 3D baseline model (curve 2). Both results

show a trend of reducing horizontal displacement with

a

r

.

•

hen the interface strength of the columns in the 3D model are

reduced to 67% of the soil strengths, the result (curve 3)

indicates an initial drop off in horizontal displacement with

a

r

,

but increases again once

a

r

> 20%. This is due to increasing

proportion of yielding elements in the remolded soil as the

columns draw closer to each other.

•

he application of the same interface strength reduction (67%

of surrounding soil strength) in the 2D equivalent strip model

has caused excessive yield in the remolded soil and led to

increased horizontal displacement with

a

r

(curve 4). A better

fit to the 3D solution is by changing the interface strength to

80% of the surrounding soil strength (curve 5). Evidently,

there needs a regime to determine an equivalent interface

strength for the strip model. This merits further research.

•

he 2D block model result (curve 6) under-predicts the

horizontal displacement when compared with the 3D baseline

model predictions. This indicates that the use of isotropic soil

properties in the 2D block model, which were derived based

on semi-empirical relationships originally for settlement

prediction under axially loading condition, have

overestimated the reduction in lateral spreading underneath

the embankment batter. The use of equivalent strips in the 2D

strip model is able to capture the interaction between the soil

and the stone column, leading to a better agreement for the

lateral deformation with the 3D baseline solution.

5 CONCLUSIONS

This paper presents a 2D FEA approach for analysing the

response of stone columns under embankment loading. The

stone columns are modeled as equivalent strips with the c

eq

and

E

eq

of the strips calculated based on weighted average area

approach, and the

φ

eq

derived based on force equilibrium

method, which requires a presumption of stress concentration

ratio of the stone column. For convenience, charts to assess the

stress concentration ratio have been generated for full depth and

floating stone columns. The solutions cover key parameters

including load levels, column spacing ratio, E

column

/E

soil

ratio

E

base

/E

column

ratio, E

base

/E

soil

ratio and column friction angles.

The accuracy of the proposed 2D strip model has been

investigated by comparing the results of the 3D baseline FEA

and the conventional composite approach. It has been shown

that the proposed strip model is preferable over the conventional

approach for the prediction of horizontal displacement.

However, further research is needed to develop a regime to

determine equivalent interface strength in the 2D strip method.

6 REFERENCES

Balaam, N.P. and Poulos, H.G. 1982. The behavior of foundations

supported by clay stabilized by stone columns.

Proc. 8th European

Conf. on Soil Mechanics and Foundation Engineering, Helsinki

.

FHWA. 1983. U.S. Department of Transportation Federal Highway

Administration (Dec, 1983) –

Design and Construction of Stone

Columns

, Vol 1. Report No. FHWA/RD-83/026.

Madhav,M.R. and Nagpure,D.D. 1996. Design of granular piles for

embankments on soft ground. Proc. 12th SE Asian Geot.Conf.,

Kaula Lumpur. 1: 285-290

Stewart, D.P. and Fahey, M. (1994). Centrifuge modelling of a stone

column foundation system, Seminar on ground improvement

techniques , Perth, Curtin Printing Services, 1: pp 101-111.

6m

10m

Soft Soil without

treatment

Embankment with 2H:1V batter

~13m

Zone 1

Zone 2

Zone 3

Bulging Bulging & Leaning

Leaning

P

Q

(a) 3D FEA (Baseline Analysis 1) with cylindrical stone columns

(b) 2D FEA (Analysis 3) with

equivalent stone column strips

(c) 2D FEA (Analysis 4) with

equivalent composite block

Max vert.

disp.

Max vert. disp.

(e) Hori. Disp.at Point Q

(d) Settlement at Point P

1

2

3

4

5

6

Axi-symmetric

20

30

40

50

60

70

80

90

100

110

0

10 20 30

Hori. displ. (mm) at point Q

Area replacement ratio a

r

150

170

190

210

230

250

270

10 15 20 25 30

Settlement (mm) at point P

Area replacement ratio a

r