2587

Technical Committee 211 /

Comité technique 211

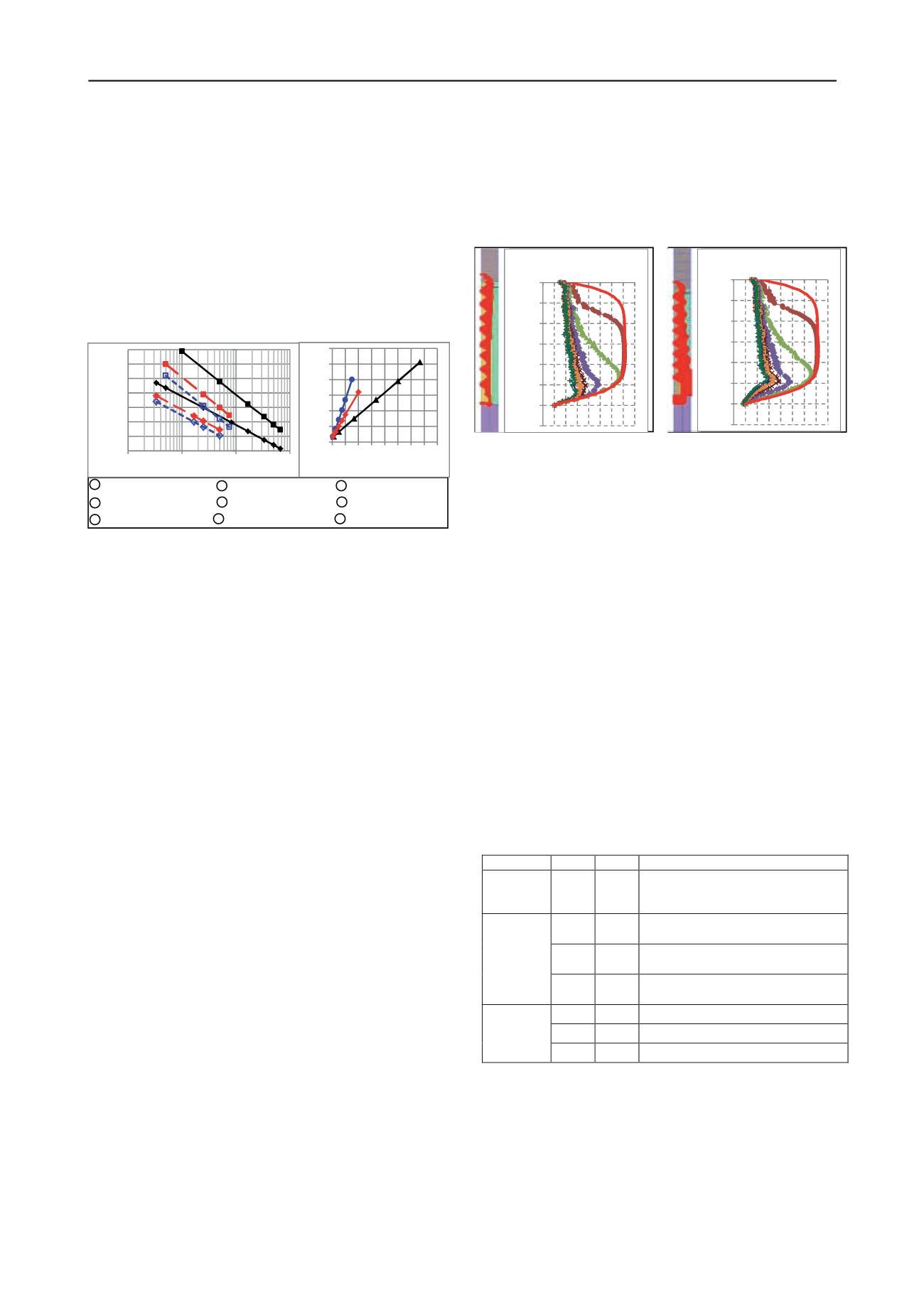

lower value as E

base

/E

soil

reduces to less than 10,

although the trend of reduction with

log(

E

base

/

E

column

) remains linear and parallel with

that for

E

base

/E

soil

≥

10 (curves 2 & 3, 5 & 6 in

Figure 6a).

•

The rate of reduction of

r

towards the column tip,

represented by the

m

, has been found to increase

linearly with

E

base

/

E

column

. Curve 7 in Figure 6b

shows such relationship and is applicable for cases

with different

b

/a ratio up to 3 (limit of parametric

range) and with

E

base

/

E

soil

≥

10. Curves 8 and 9

delineate the corresponding curves for cases with

E

base

/

E

soil

= 2 and 1.

Figure 6. Stone column with compressible base -elastic solution

3.3

Stone columns on compressible soils - elasto-plasticity

The effect of compressible base on stress concentration

n

is now

discussed based on Mohr Coulomb model. In particular, the

soils surrounding and below the stone columns have been

appraised alternatively using (i) effective shear strength (c,

φ

)

and (ii) undrained shear strength s

u

.

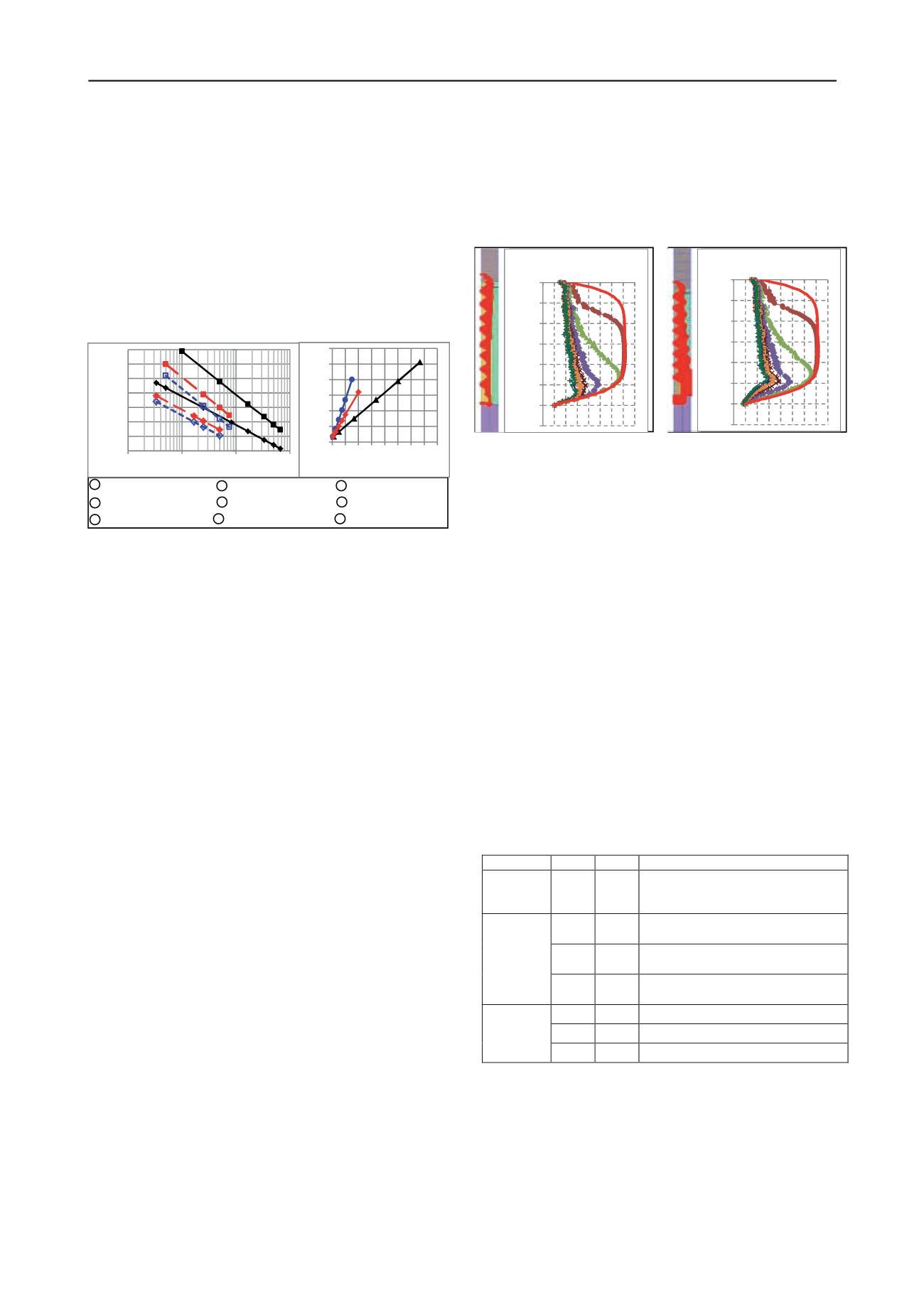

Figure 7a shows the computed

n

under different fill loads for

the same case as in Figure 2,except that the column is founded

on compressible soil that is represented by

c

-

φ

materials. The

stress concentration curves initially follow identical paths as

those shown in Figure 3b until they intercept the lower equal

settlement plane and thereafter trace along the curve of the

elastic solution at the column base. To explain this stress

transfer mechanism, the material stress state of the model at the

end of simulation (under 140kPa fill stress) is presented (inset

in Figure 7a). As before, yielding of the column follows a top-

down process. While there is significant yielding of the column

due to high stress ratio, there is little yield in the surrounding

soil especially towards the column base because of sufficient

confinement even with an adopted soil friction angle as low as

22°. Since the soil is elastic, the reduction of

n

due to the

compressible elastic base soil can be superimposed directly onto

the aforementioned reduction due to yielding of column.

Figure 7b presents the results for the case where s

u

= 30kPa

has been adopted for the soils surrounding and below the

column. Significant yielding occurs in the soils, which has

altered the shape of the stress concentration curves towards the

column base as compared to that of the c-

φ

soils. However the

differences are not great and for the purpose of assessing

n

, the

problem can be idealised by assuming that there is no failure in

the surrounding soil so that its behavior is essentially elastic.

3.4

Procedure for assessing stress concentration

The following procedure for assessing the stress concentration

of the stone columns under fill embankment may be proposed:

Step 1

– Assessing the stress concentration

n

along column

depth by using charts such as Figure 4, which have accounted

for the influence of load level, column spacing, modulus ratio of

column and surrounding soil, and yield of the stone column.

Step 2

– Assess the influence of the compressible base soil

on

n

based on elasticity by the following equation:

n

=

n

max

×

r

(4)

where

r

is the stress concentration reduction ratio given in Eq.

3, which is a function of

ξ

and

m

given in Figure 6.

n

max

is the

maximum elastic

n

value below the turning point of each

normalised

z·

γ

/q

a

−

n

curve in Figure 4.

Step 3

– Superimpose the solution from Step 2 onto that of

Step 1. Thereby, the final

n

along the depth of the column is the

lower of the two solutions at the same depth.

Figure 7. Stone column on compressible (a)

c

-

φ

and (b) s

u

soil

4 COMPARISON WITH FULL 3-D MODELLING

The accuracy of plane strain idealisation of stone columns using

equivalent strips in 2D FEA was investigated under self-weight

load imparted by a 6m high embankment with 2H:1V batter.

The analyses undertaken for the investigation include

:

Analysis

1

- Full 3D FEA of embankment over stone columns modeled

by solid elements;

Analysis 2

- Axisymmetric FEA of a unit cell

consisting stone column;

Analysis 3

- 2D plane strain FEA with

the stone columns modeled as strips; and

Analysis 4

- 2D FEA

with the soil and columns modeled as equivalent block. The 2D

and 3D FEA were carried out using software programme

PLAXIS 2D and PLAXIS 3D, respectively.

Table 1 summarises the adopted parameters for all analyses.

The 3D FEA is considered a baseline model that comprises a

13m long segment of embankment over soft clay treated with

stone columns which are founded on compressible soil. The

analysis was repeated with the 0.9m diameter stone columns

spaced at 1.7m, 2m and 2.5m in triangular pattern. The 3D FE

mesh is shown in Figure 8. The stone columns are modeled

using 15 nodes wedge element with interface elements at the

column-soil contact. Two cases of interface strength of 100%

and 67% of the surrounding soil strengths have been considered.

Table 1. FEA Model Parameters

Soil surrounding columns are E

soil

= 3MPa, c

soil

= 2kPa,

φ

soil

= 26º;

Soil beneath columns are E

base

= 3MPa, c

soil

= 5kPa,

φ

soil

= 28º

In Analysis 3, a 2D plane strain idealisation of the stone

columns using equivalent strips was investigated. The strips are

divided into several segments, each of which has different

strength properties that correspond to the varying stress

concentration along the column depth. The dimension and

spacing of the 2D strips are as per those outlined in Figure 1.

Analysis 4 presents a conventional 2D approach in which the

entire treated soil is represented by a single block with the

Analysis

b/d

a

r

Stone Column Parameters

1,2

3D FEA

2.0,

2.3,

2.9

0.26,

0.19,

0.12

E

col

=50MPa, c

col

=0kPa,

φ

col

= 40º

3 - 2D

FEA

(strips)

2.0

0.26

E

strip

=26MPa, c

strip

~1kPa,

φ

strip

= 36.5 -

38° along shaft , = 35.5 near base

2.3

0.19

E

strip

=22MPa, c

strip

~1kPa,

φ

strip

= 35.5º-

37° along shaft ; =34° near base

2.9

0.12

E

strip

=18MPa, c

strip

~1kPa,

φ

strip

= 34.5º-

35.5° along shaft; = 33° near base

4 - 2D

FEA

(equiv.

block)

2.0

0.26

E

block

=6MPa, c

block

~1kPa,

φ

block

= 30º

2.3

0.19

E

block

=6MPa, c

block

~1kPa,

φ

block

= 30º

2.9

0.12

E

block

=6MPa, c

block

~1kPa,

φ

block

= 30º

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

b

/

a

= 3,

E

base

/

E

soil

≥

10

b

/

a

= 2,

E

base

/

E

soil

≥

10

b

/

a

= 3,

E

base

/

E

soil

=2

b

/a = 3,

E

base

/

E

soil

=1

b

/

a

= 2,

E

base

/

E

soil

=2

b

/

a

= 2,

E

base

/

E

soil

=1

b

/a

≤

3,

E

base

/

E

soil

≥

10

b

/

a

≤

3,

E

base

/

E

soil

=2

b

/a

≤

3,

E

base

/

E

soil

=1

(a)

(b)

(a)

(b)

60kPa – 140kPa

40kPa

Fill

Load

20kPa

Elastic

solution

0.5

1.5

2.5

3.5

4.5

5.5

6.5

7.5

0.01

0.1

1

10

Influenced zone

ξ=

y/a

E

base

/E

column

0

10

20

30

40

50

60

0 1 2 3 4 5 6 7 8

m

E

base

/E

column

-14

-12

-10

-8

-6

-4

-2

0

0 2 4 6 8 10121416

Depth z below top of stone column (m)

Stress Concentration ratio

n

-14

-12

-10

-8

-6

-4

-2

0

0 2 4 6 8 10 12 14 16

Depth z below top of stone column (m)

Stress Concentration ratio

n