2596

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

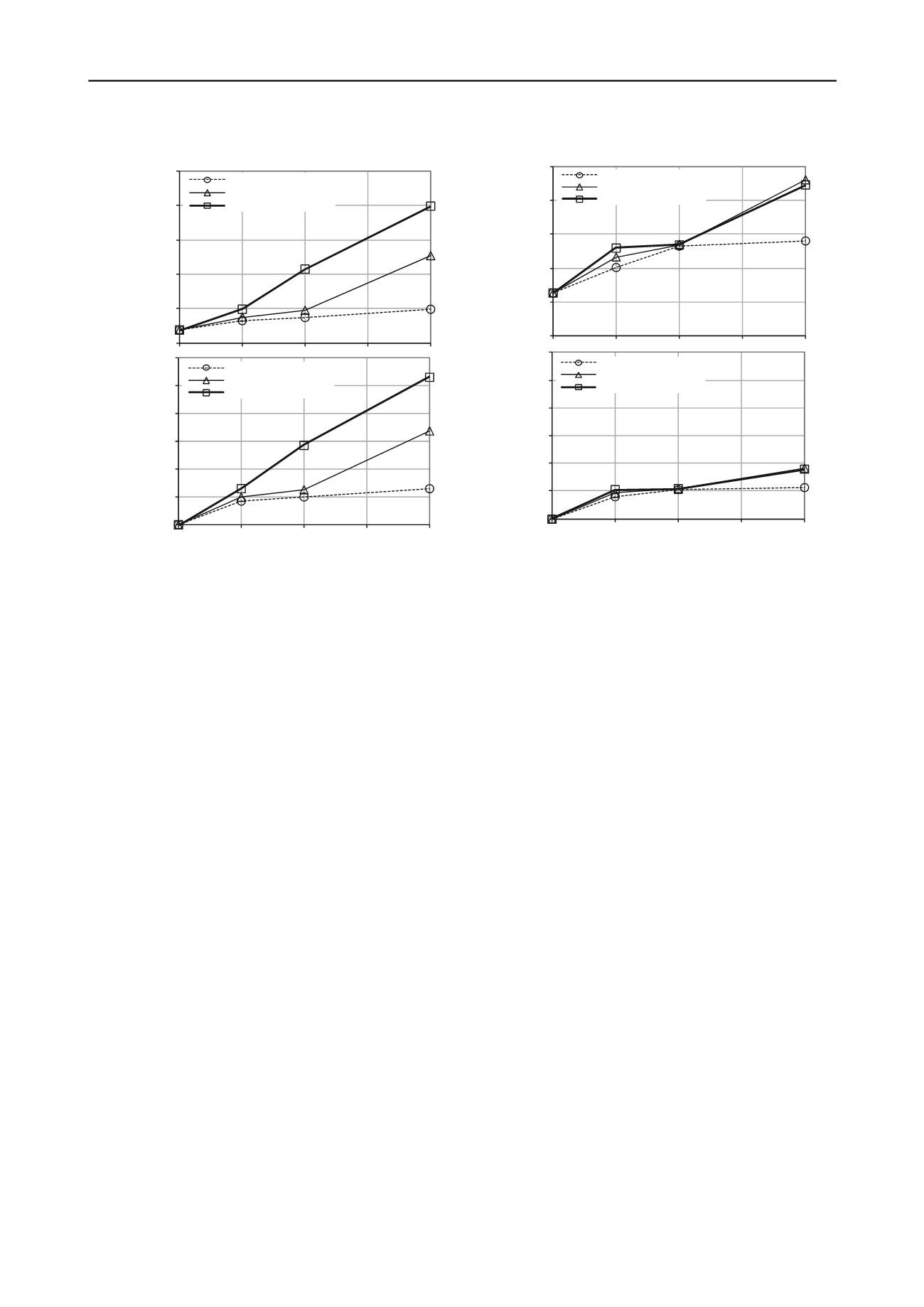

Figure 4. Improvement in UCS for cement content of 0.5%.

3.5

Effect of Cement Content on UCS

The range of the cement content that was chosen in this study

(0.5% to 1.0%) is indicative of lightly-cemented sands.

However, the results presented in Figs. 2 to 5 indicate a clear

difference in the performance of the composite specimens that

were stabilized with 0.5% cement and specimens stabilized with

1.0%, particularly with regards to the contribution of the fibers

to the improved compressive strength.

For specimens that were not reinforced with fibers, the

increase in cement content from 0.5% to 1.0% increased the

unconfined compressive strength from 15 kPa to 50 kPa. With

the addition of fibers, results showed that the UCS could be

improved by more than 10 times for a cement content of 0.5%

but only to 3.7 times for the cement content of 1.0%, indicating

a decreased relative efficiency of the fibers at improving the

compressive strength as the cement ratio increases.

It should be noted however that the actual maximum value

(largest fiber content and fiber length) of the unconfined

compressive strength was still higher (about 185 kPa) for the

cement content of 1.0% compared to the maximum value (159

kPa) measured for the cement content of 0.5%. For the smaller

fiber contents and fiber lengths, the values of the UCS for the

cement content of 1% were all higher than those of the 0.5% at

the same fiber content and fiber length, indicating that the

magnitude of the improved UCS was larger for the higher

cement content.

4 CONCLUSION

Based on the results of 20 unconfined compression tests that

were conducted in this study on fiber-reinforced lightly-

cemented sands, the following conclusions can be drawn:

1. The behavior of specimens with higher cement contents is

more brittle compared to specimens with lower cement

contents. However, brittleness decreased with the

inclusion of fibers and the energy absorption capacity

increased as the fiber content and length increased.

2. For the smaller cement content, the stiffness of the

specimens was not affected by the addition of fibers,

except for the cases of 20mm fibers with fiber contents

0

40

80

120

160

200

0.00

0.25

0.50

0.75

1.00

UnconfinedCompressive Strength (kPa)

Fiber Content, FC (%)

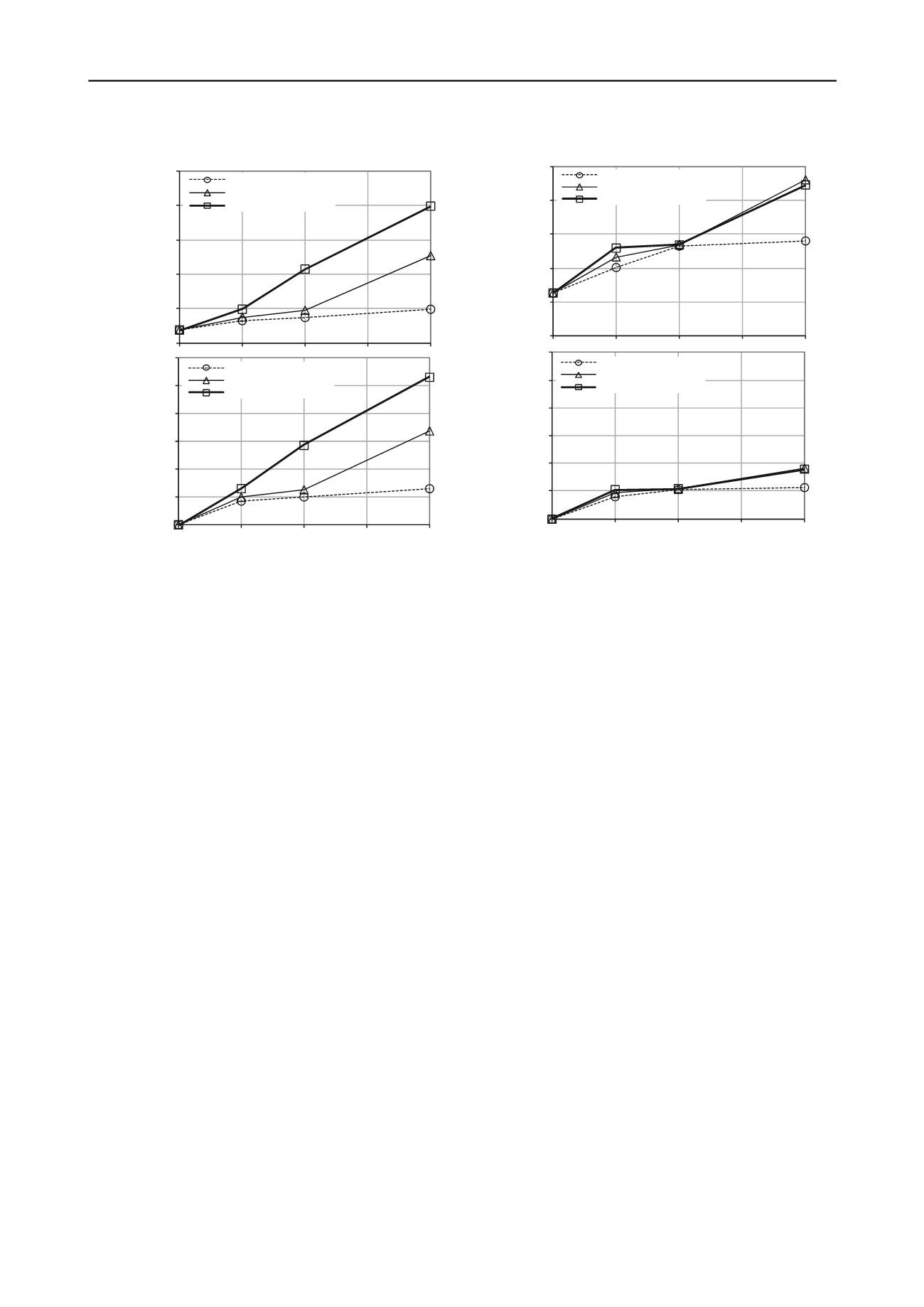

Cement Content = 1.0%

Fiber Length = 6mm

Fiber Length = 12mm

Fiber Length = 20mm

0

2

4

6

8

10

12

0.00

0.25

0.50

0.75

1.00

UCS (Fibers) / UCS (No Fibers)

Fiber Content, FC (%)

Fiber Length = 6mm

Fiber Length = 12mm

Fiber Length = 20mm

0

40

80

120

160

200

0.00

0.25

0.50

0.75

1.00

UnconfinedCompressive Strength (kPa)

Fiber Content, FC (%)

Cement Content = 0.5%

Fiber Length =6mm

Fiber Length =12mm

Fiber Length =20mm

0

2

4

6

8

10

12

0.00

0.25

0.50

0.75

1.00

UCS (Fibers) / UCS (No Fibers)

Fiber Content, FC (%)

Fiber Length =6mm

Fiber Length =12mm

Fiber Length =20mm

Figure 5. Improvement in UCS for cement content of 1.0%.

of 0.25% and 0.50%, where the stiffness was found to be

improved. For the higher cement content fibers could

result in a softer initial response particularly for higher

fiber contents and longer fibers.

3. For the both cement contents used, results indicated a

consistent increase in the unconfined compressive

strength with fiber content. The cement content played a

significant role in defining the improvement ratio of the

UCS, with the ratio varying from 2 (smallest fiber

content and fiber length) to 10 (largest fiber content and

fiber length) for a cement ratio of 0.5%, and from about

2 to 4 for the larger cement ratio of 1.0%.

4. For a cement content of 0.5%, as the fiber length

increased, the UCS increased and the strain at failure

increased, indicating improved ductility, with the effect

of fiber length being evident at higher fiber contents

compared to lower fiber contents. For the larger cement

content of 1.0%, the effect of fiber length on the

unconfined compressive strength was less significant.

5 ACKNOWLEDGEMENTS

The authors would like to acknowledge the support of the

Lebanese National Council for Scientific Research (LNCSR)

for funding this research program.

6 REFERENCES

Maher M.H. and Ho Y.C. 1993. Behavior of fiber-reinforced cemented

sand under static and cyclic loads.

American Society for Testing

and Materials

16, 330-338.

Kaniraj S.R. and Havanagi V.G. 2001. Behavior of cement-stabilized

fiber-reinforced fly ash-soil mixtures.

Journal of Geotechnical

Engineering

127, 574-584.

Consoli et. al. 1998. Influence of fiber and cement addition on behavior

of sandy soil.

Journal of Geotechnical Engineering

124, 1211-1214.

Consoli et. al. 2002. Engineering behavior of a sand reinforced with

plastic waste.

Journal of Geotechnical Engineering

128, 462- 472.

Sobhan K. and Mashnad M. 2002. Tensile strength and toughness of

soil-cement-fly-ash composite reinforced with recycled high-

density polyethylene strips.

Journal of Materials in Civil

Engineering

14, 177-184.