2599

Technical Committee 211 /

Comité technique 211

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The monitoring proved to be particularly valuable because of

the occurrence of two incidents during construction.

5.2

Incident 1

Incident 1 occurred during the excavation of building pit A. The

situation at that time is illustrated by Figure 8 (by a recommend-

dable, remotely operable, permanent webcam!) and Figure 9.

Figure 8 Overview building pit (at the time of incident)

Figure 9. Top view building pit (at the time of incident; © Google)

To limit the displacements the execution sequence has been

that, after placement of the sheet piles and the excavation for the

NAP -1,5m and -5,0m struts, the water table was first set up

again before wet excavation to NAP -10,5m commenced. After

hardening of the underwater concrete floor, the water table was

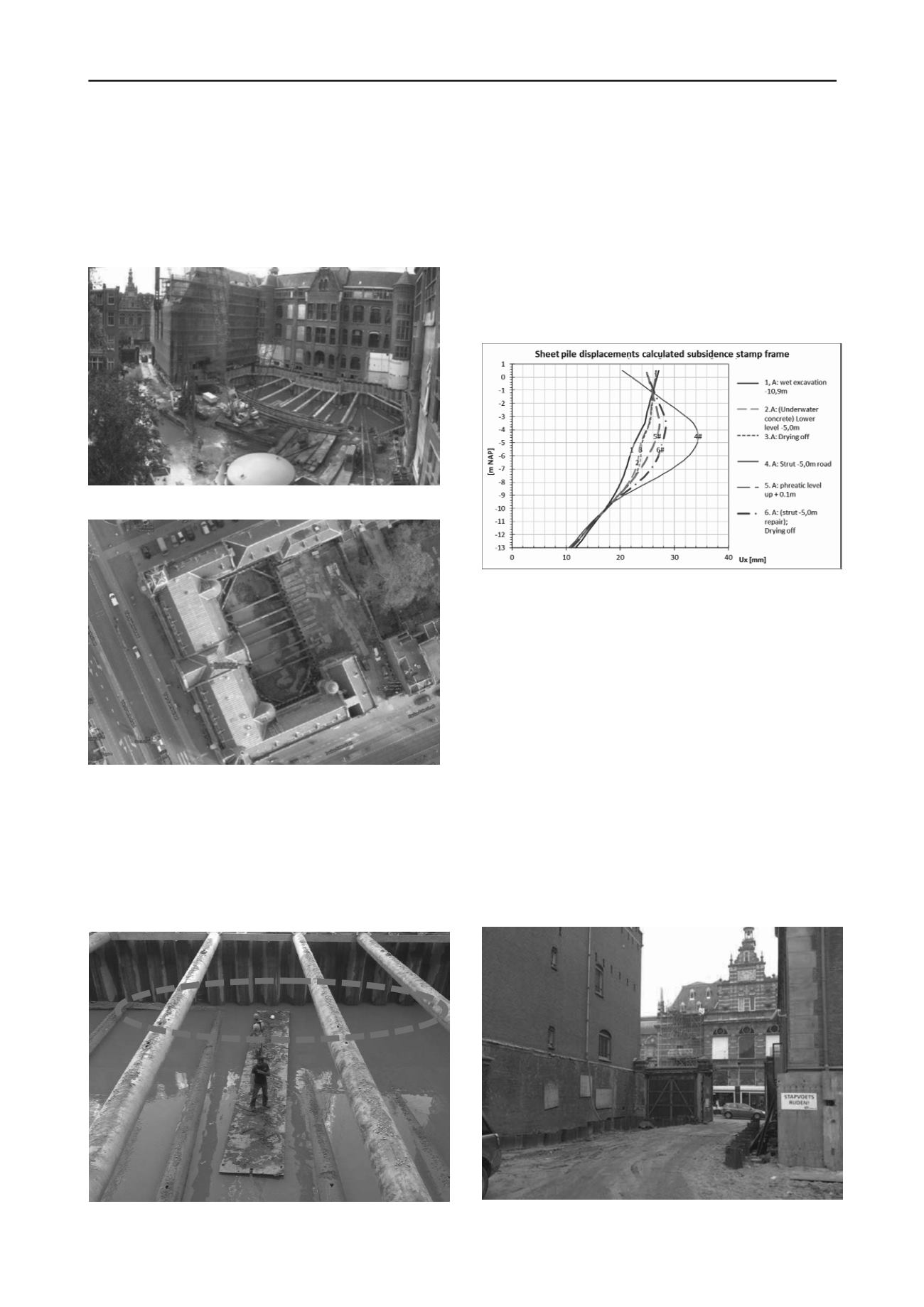

lowered again. It was then timely discovered that the -5,0m

struts and girder were not in position, see Figure 10. Pumping

was stopped immediately to access the situation.

Figure 10. Situation at 2

nd

level girder (collapsed during excavation)

In order to be able to inspect the girder and struts, the water

table had to be lowered further than calculated (-6,5m without

strut). It was found that, probably because of excavating under

the girder, it’s consoles were removed, thus causing it to ‘hang

by a tread’. Because of the extensive monitoring and

modelling, an alternative model could be made very quickly

based on actual deformations, from which it could be concluded

that the deformationsresulting from the mitigating measures

stayed within acceptable boundaries, see Figure 11. Thus,

within three weeks and without significant delay in

construction, the strut and girder could be repaired allowing for

further excavationof the pit.

Figure 11. Inclinometer & predictions after incident at girder/strut -5.0m

5.3

Incident 2

Incident 2 occurred during the excavation of the entrance at

building pit B. The situation is illustrated by Figures 12 (before)

and 13 (after excavation). At the left side of the pictures, a listed

building at Paulus Potterstraat 44 (PP44) is located. During the

excavation of building pit B, this building started to settle, as

can be seen in Figure 15. The main concern however was that

the side at the entrance settled significantly more than the

opposite side, thus potentially causing damage.

In November 2009 the monitoring showed that the

settlement rate increased alarmingly. The frequency of

monitoring was immediately increased and owner, contractor,

consultants, insurer and the municipality intensively discussed a

solution. This was found in a combination of allowing more

deformation as long as no damage resulted from frequent

building inspection and, more importantly, the remedial

measure of pre-stressing the NAP -4,0m strut with 150 kN/m.

The last measure resulted in a stabilisation of deformations that

has held up to now. No damage to PP44 was detected.

Figure 12. Building pit at PP44 before incident