2592

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

would perform in a completely satisfactory way for the highest

cemented mixtures (for 5% and 7% of cement content).

0

1000

2000

3000

4000

5000

6000

1 2 3 4 5 6 7 8 9 10 11 12

E

ur

(MPa)

Test condition

1 2%C;

'

c

=30 kPa

2 2%C;

'

c

=80 kPa

3 2%C;

'

c

=250 kPa

4 4%C;

'

c

=30 kPa

5 4%C;

'

c

=80 kPa

6 4%C;

'

c

=250 kPa

7 5%C;

'

c

=30 kPa

8 5%C;

'

c

=80 kPa

9 5%C;

'

c

=250 kPa

10 7%C;

'

c

=30 kPa

11 7%C;

'

c

=80 kPa

12 7%C;

'

c

=250 kPa

Test condition

n/C

iv

0.21

=36

n/C

iv

0.21

=29

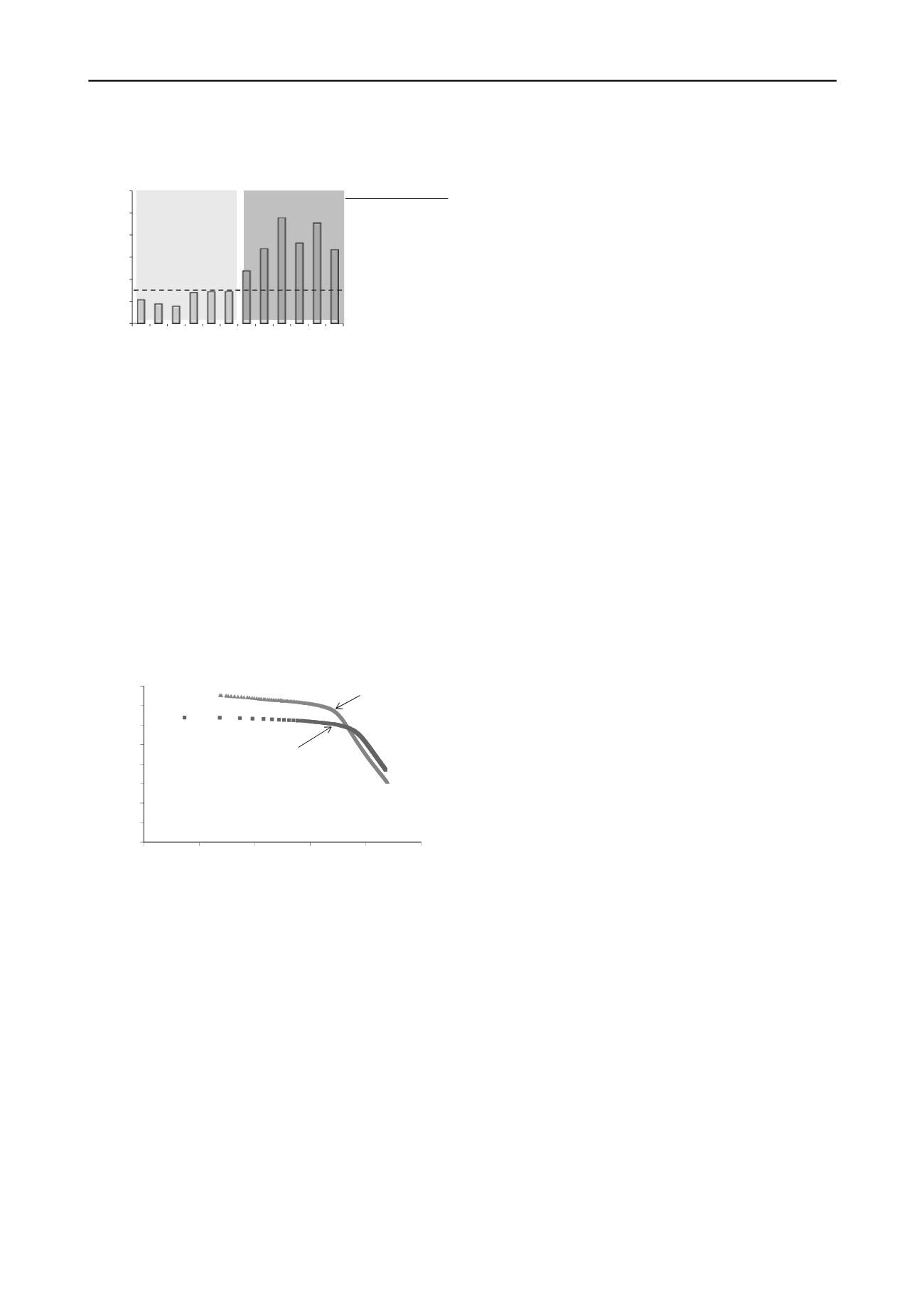

Figure 6. Stiffness modulus obtained in the unload-reload cycles.

5 COMPRESSIBILITY PARAMETERS

One-dimension compression tests in oedometer cells with

constant rate of deformation (CRD) were performed over soil-

cement specimens in the four moulding conditions presented in

Table 1. The preparation of the different mixtures for these tests

followed the same procedure of the other tests, as expressed

briefly in section 2. Due to the size of the mould, the static

compaction was performed in one layer, although the soil was

placed in several stages followed by tapping. For the calculation

of the mean effective stress (p’) in each test the value of the

coefficient of earth pressure at rest (k

0

) was considered equal to

1 due to the high compaction degree that the specimens were

subjected during moulding (>80% of the Modified Proctor test).

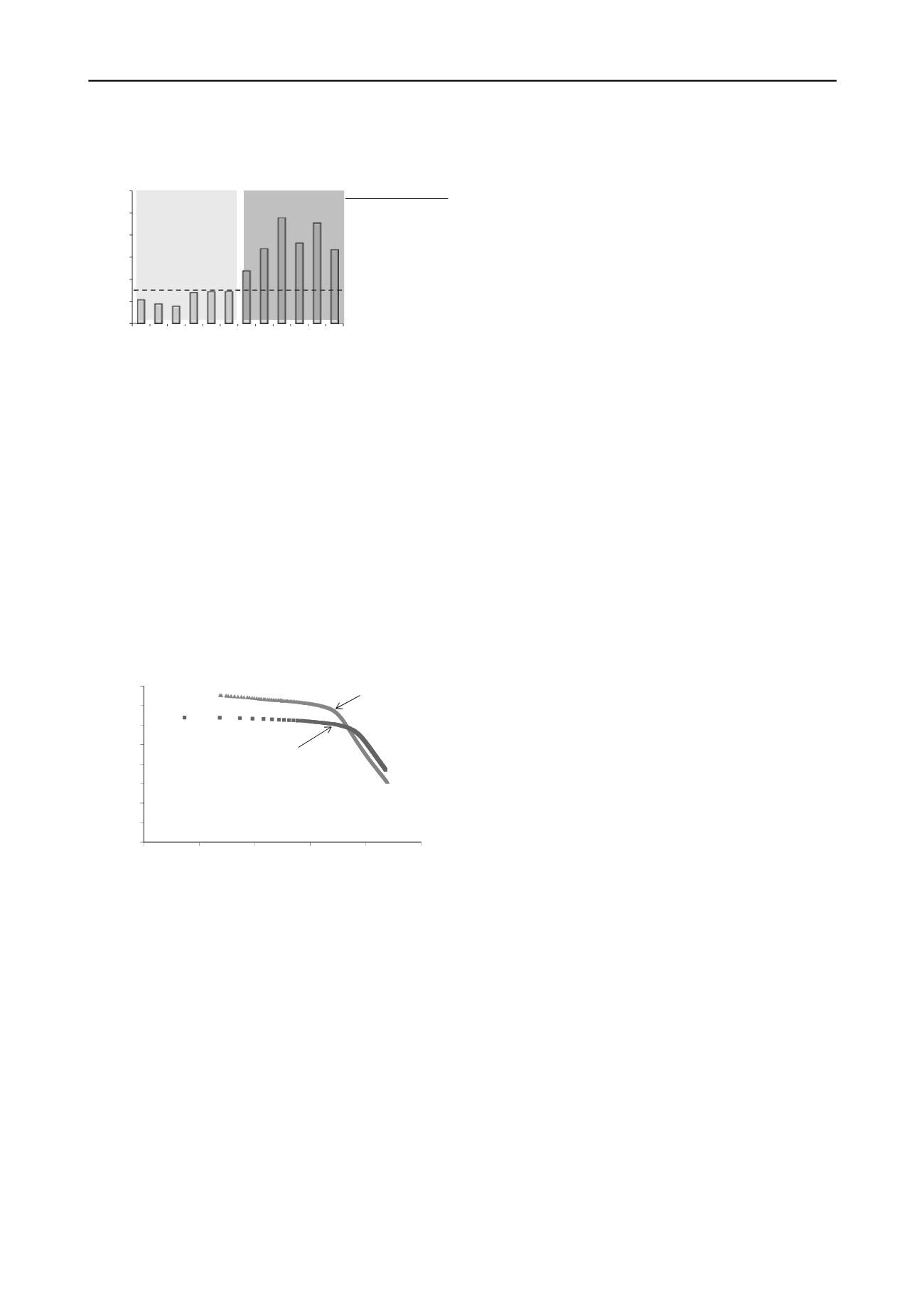

Figure 7 shows two of those tests, corresponding to two

different porosity cement ratios, indicating that these

compressibility curves do not seem to converge.

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.001 0.010 0.100 1.000 10.000 100.000

e

p' (MPa)

n/C

iv

0.21

= 29

n/C

iv

0.21

= 36

Figure 7.Void ratio against mean effective stress for two different

porosity/cement ratios

However, plotting the tests performed over specimens with

the same porosity cement ratio, a unique compressibility line

was obtained. The same has happened for the other two tests

with the other porosity cement ratio of 36. On the contrary,

when specimens with the same cement content but different

void ratio were represented no unique line was obtained. These

results indicate that this ratio can better reproduce the behaviour

in one-dimensional compression than the cement content or

initial void ratio alone.

6 CONCLUSIONS

This paper presented a great number of data from different tests.

Together, they allowed a better understanding of the artificially

cemented soil used in this work. Compressive and tensile

strength, strength envelopes, stiffness parameters and one

–

dimensional behaviour were some of the most important issues

studied. The adjusted porosity/cement ratio revealed to be very

consistent and useful for the analysis of the unconfined

compression strength since a unique trend was obtained

between this variable and n/C

iv

0.21

. A similar trend was obtained

for the indirect tensile strength performing tests over specimens

moulded in the same conditions. The comparison of the two

curves provided a relationship between indirect and

compressive strength of about 11%.

The strength envelope values of the cemented specimens

tested in triaxial compression were obtained through a

procedure based on the Mohr’s circles analysis to s

olve the lack

of representativeness of principal stress analysis due to non

correspondence of the real localised shear locus. In fact, strain

localisation is unavoidable in these very stiff materials, and

consequently, the global stress-strain measurements are no

longer representative of the conditions throughout the shearing

process. Two peak strength envelopes were obtained for each

n/C

iv

0.21

(n/C

iv

0.21

=36:

’=30º and c’=

253 kPa; n/C

iv

0.21

=29:

’=39º and c’= 589

kPa), showing once again the convenience

of this ratio for the analysis of these mixtures behaviour.

This ratio also seems to be very useful to reproduce the one

dimensional compression behaviour of the mixture, since for

each n/C

iv

0.21

a single line was obtained for higher stresses.

7 ACKNOWLEDGEMENTS

This research was developed under the activities of FCT

(Portuguese Foundation for Science and Technology) research

unit CEC, in FEUP [PTDC/ECM/ 099475/2008], and financed

by the European Community (QREN/UE/FEDER), Operational

Program for Competitive Factors "COMPETE".

8 REFERENCES

ASTM 1998. D 2487-98 Standard practice for classification of soils for

engineering purposes (Unified Classification System)

Burland J. B. 1990. On the compressibility and shear strength of natural

clays.

Géotechnique

40(3), 329-378.

CEN 2003.EN 13286-42 - Unbound and hydraulic bound mixtures. Test

method for the determination of the indirect tensile strength of

hydraulically bound mixtures, ComitéEuropéen de Normalisation

Chang T. S. and Woods R.D. 1992. Effect of particle contact bond on

shear modulus.

Journal of Geotechnical and Geoenvironment

Engineering

118(GT8), 1216-1233.

Consoli N.C., Viana da Fonseca A., Cruz R., Rios S. 2011.

Voids/Cement ratio controlling tensile strength of cement treated

soils.

Journal of Geotechnical and Environmental Engineering

,

137(11), 1126-1131 (doi:10.1061/(ASCE)GT.1943-5606.0000524)

Consoli N.C., Viana da Fonseca A., Rios S., Cruz R. and Fonini A.

2012.Parameters controlling stiffness and strength of artificially

cemented soils.

Géotechnique

62(2),

177-183 (doi:

10.1680/geot.8.P.084)

Consoli N.C., Foppa D., Festugato L. and Heineck K. 2007.Key

Parameters for Strength Control of Artificially Cemented Soils,

Journal of Geotechnical and Geoenvironmental Engineering

133(2), 197-205.

Gasparre A. 2005. Advanced laboratory characterisation of London

Clay. PhD dissertation presented to the University of London

Lorenzo G. and Bergado D. 2004.Fundamental parameters of cement-

admixed clay - New Approach.

Journal of Geotechnical and

Geoenvironmental Engineering

130(10), 1042-1050.

Rios S., Viana da Fonseca A. andBaudet B. 2012. The effect of the

porosity/cement ratio on the shearing behaviour of cemented

soil.

ActaGeotechnica

(accepted)

Viana da Fonseca, A. 1998. Identifying the reserve of strength and

stiffness characteristics due to cemented structure of a saprolitic

soil from granite. The Geotechnics of Hard Soils - Soft Rocks,

Evagelista and Picarelli (eds), Balkema, Roterdam

Viana da Fonseca A., Carvalho J., Ferreira C., Santos J.A., Almeida F.,

Pereira E., Feliciano J., Grade J. and Oliveira A. 2006.

Characterization of a profile of residual soil from granite combining

geological,

geophysical

and mechanical

testing

techniques.

Geotechnical and Geological Engineering

24, 1307-

1348