2591

Technical Committee 211 /

Comité technique 211

breakage in the cement, while dilation involves particle

rearrangement that is only possible after bonding breakage.

Assuming only compressive volumetric deformations up to the

point of zero dilation, beyond this point yielding exists, which

indicates that the onset of cement breakage is progressive

starting even before peak. However, being the peak strength not

frictional but controlled by the cement yielding, then most

destructuration may take place only at peak.

Table 1.Moulding conditions of the specimens for the triaxial tests

Moulding

Point

%C

(%)

γ

d

(kN/m

3

)

e

0

w

(%)

n/C

iv

0.21

UCS

(kPa)

σ’

c

(kPa)

2

16.6 0.61 12

36

800 30

2

16.5 0.62 12

36

800 80

1

2

16.7 0.60 12

36

800 250

4

15.4 0.74 12

36

800 30

4

15.7 0.71 12

36

800 80

2

4

15.5 0.73 12

36

800 250

5

16.9 0.59 12

29

2000 30

5

17.0 0.58 12

29

2000 80

3

5

17.0 0.58 12

29

2000 250

7

16.3 0.66 12

29

2000 30

7

16.5 0.63 12

29

2000 80

4

7

16.7 0.61 12

29

2000 250

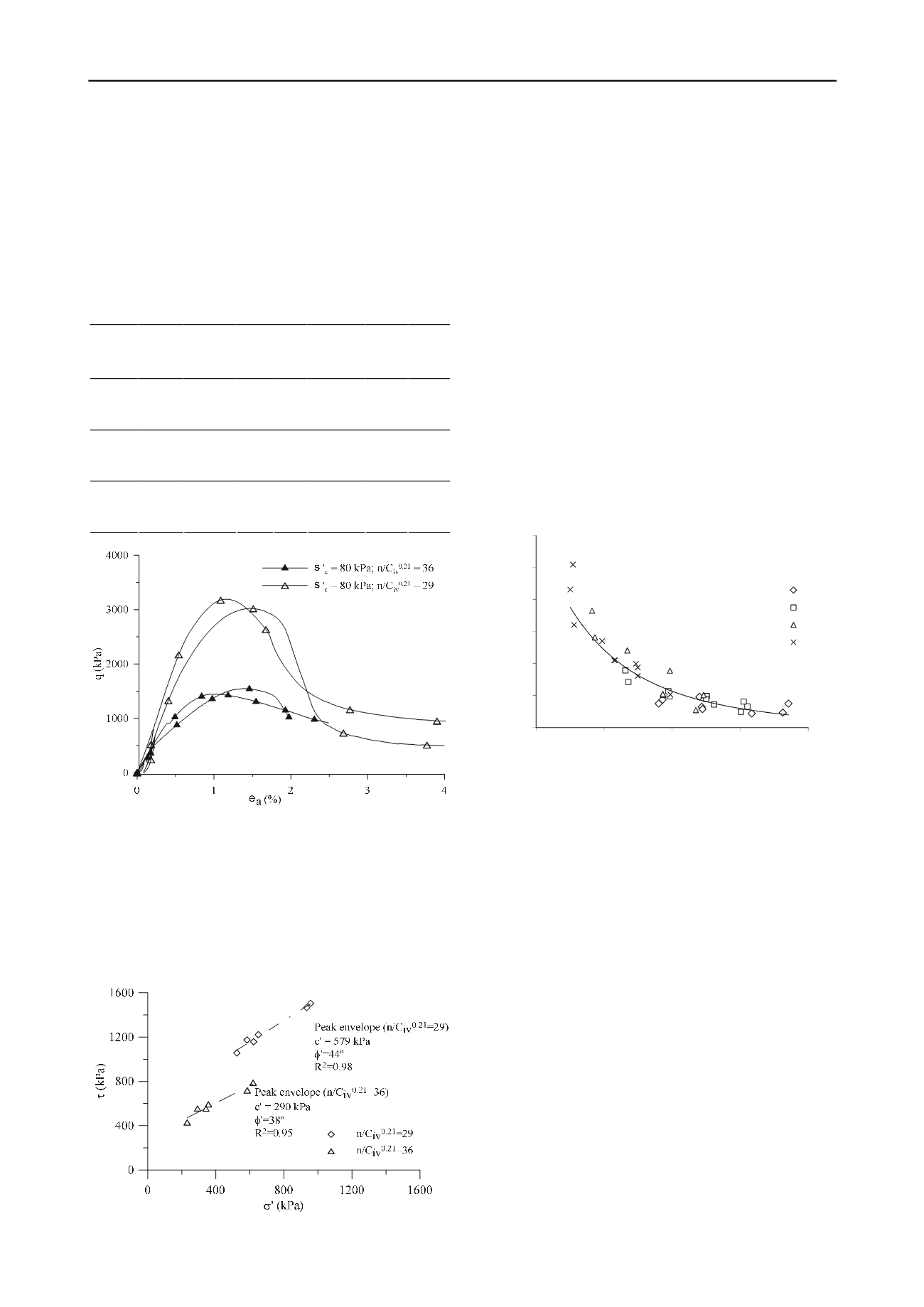

Figure 3. Stress-strain curves for the confining pressure of 80 kPa.

All the cemented specimens tested in triaxial tests suffered

strain localisation. Therefore, it becomes difficult to rely on the

local instrumentation at strain levels close and after the peak,

but especially at ultimate conditions. In that sense, the stress

invariants such as the deviator stress (q) and the mean effective

stress (p’) were not considered representative of the stress state

and thus, the stresses acting on the shear plane were calculated

by the procedure used by Gasparre (2005) based on the Mohr

circles and taking into account the post rupture analysis

described by Burland (1990).

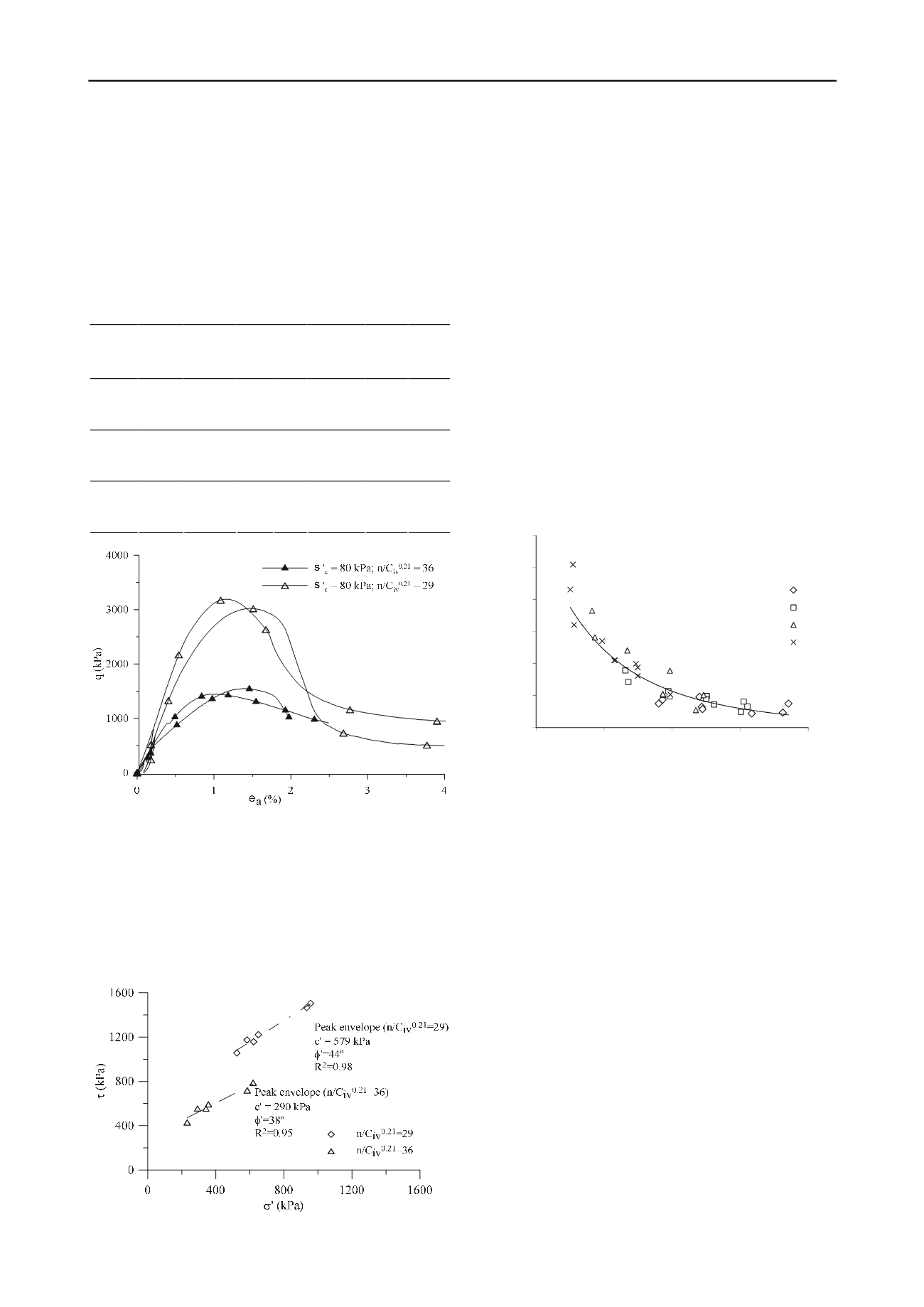

Figure 4.Peak strength envelopes by adjusted porosity/cement ratio.

In Figure 4 the stresses acting on the plane are plotted on a

(σ’,

) graph for peak conditions from which the correspondent

strength parameters were obtained. The points are assigned to

each adjusted porosity/cement ratio (n/C

iv

0.21

) expressed before.

It is interesting to notice that for peak conditions two strength

envelopes were obtained depending on the index ratio. The

adjusted porosity/cement ratio influences the peak angle of

friction and cohesion intercept, being the peak envelope for the

index n/C

iv

0.21

=29 higher than that for the index equal to 36.

This could have been predicted from moulding characteristics as

each ratio corresponds to different UCS.

4 STIFFNESS PARAMETERS

4.1 Initial tangent stiffness

The unconfined compression tests were performed with local

measurement of deformation using LDT’s an

d so the stiffness

modulus could be evaluated. An initial tangent modulus (E

ti

)

was then calculated based on the linear part of the stress-strain

curve.

Plotting this modulus against the adjusted

porosity/cement ratio for the 16 tests presented above, as

Figure 5 shows, it can be concluded that the general adjustment

of the data is quite reasonable.

E

ti

= 2E+09 (n/C

iv

0.21

)

-4.169

R² = 0.85

0

1000

2000

3000

4000

5000

6000

20

25

30

35

40

E

ti

(MPa)

n/C

iv

0.21

2%C

3%C

5%C

7%C

Figure 5. Indirect tensile strength and unconfined compression strength

against the adjusted porosity/cement ratio

As expected, stiffness parameters are more scattered than

strength parameters because strain measurements are always

more sensitive to non-homogeneities of the specimen and

anchors are introduced in the specimen in single reference

points. On the contrary, strength measurements capture more

easily an average value of the whole specimen.

4.2 Unload-reload moduli

In the triaxial compression tests reported above, a small

static cycle was performed during shearing, between 30% and

15% of the expected peak deviatoric stress. These loads were

selected to avoid soil yielding before the cycles so the modulus

could be assumed elastic. Figure 6 summarizes the results of the

unload-reload moduli (E

ur

) obtained for the two adjusted

porosity/cement ratio. The values of E

ur

obtained from these

triaxial tests are higher than the initial tangent modulus (E

ti

)

obtained in the unconfined compression tests presented in

Figure 5. This can be considered expected because E

ur

is usually

assumed to follow an elastic pattern, if performed at low ranges

of cyclic stress, while in the initial monotonic loading path

some compliance errors of strain gauges may be presented. This

graph also evidences a clear and almost discrete increase in the

stiffness modulus values for the specimens with n/C

iv

0.21

=29

(5% and 7% cement contents) in comparison with the

specimens with distinct ratio n/C

iv

0.21

=36 (2% and 4% cement

contents). This could be even clearer if the instrumentation