2590

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

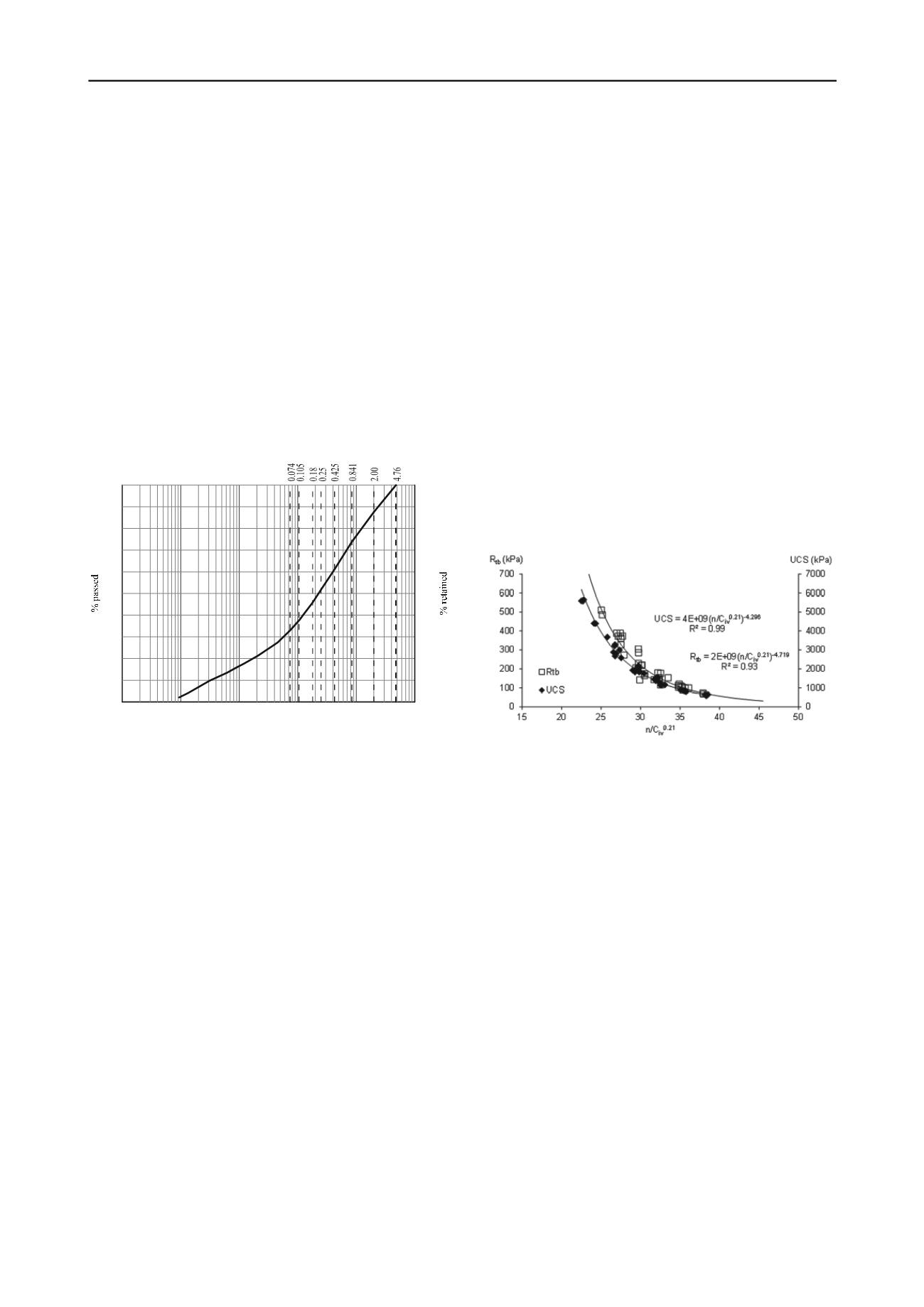

although a low plasticity index was obtained (I

P

=w

L

-w

P

=34%-

31%=3%). From the particle size distribution curve presented in

Figure 1 an average diameter D

50

equal to 0.25 mm was

obtained, as well as uniformity and curvature coefficients of 113

and 2.7 respectively.A high strength Portland cement (CEM I

52,5R) of grain density equal to 3.15 was used as the cementing

agent in order to speed up the laboratory tests.

The experimental program is performed with specimens

made by the mixture of silty sand, Portland cement and tap

water that is compacted statically in three layers in a stainless

steel mould. For each specimen, a quantity of fines equal to the

weight of cement to be introduced was removed from the soil,

in order to have the same grain size distribution curve in the

mixture of soil-cement as in the soil itself. Following this

procedure the dry density of the soil was also constant

throughout the study even though the cement content changed.

The specific gravity of the cement-soil mixture was calculated

as a weighted average of those of the soil (Gs=2.72) and of the

cement (Gs=3.15), and thus it was different for different cement

contents.

0.0001

0.001

0.01

0.1

1

10

Grain size (mm)

0

10

20

30

40

50

60

70

80

90

100

100

90

80

70

60

50

40

30

20

10

0

ASTM sieves series (mm)

Figure 1. Grain size distribution curve

3 STRENGTH PARAMETERS

3.1 Unconfined compression strength

Strength properties of the cemented sand were evaluated in

different ways by means of unconfined compression tests,

indirect tensile tests, as well as triaxial tests. First, several

specimens moulded to have different cement contents (2%, 3%,

5% and 7%) and dry unit weights (16.4, 17.2, 18.0 and

18.8 kN/m

3

) were tested in unconfined compression in a total of

16 tests. In these tests, the water content was kept equal to 12%.

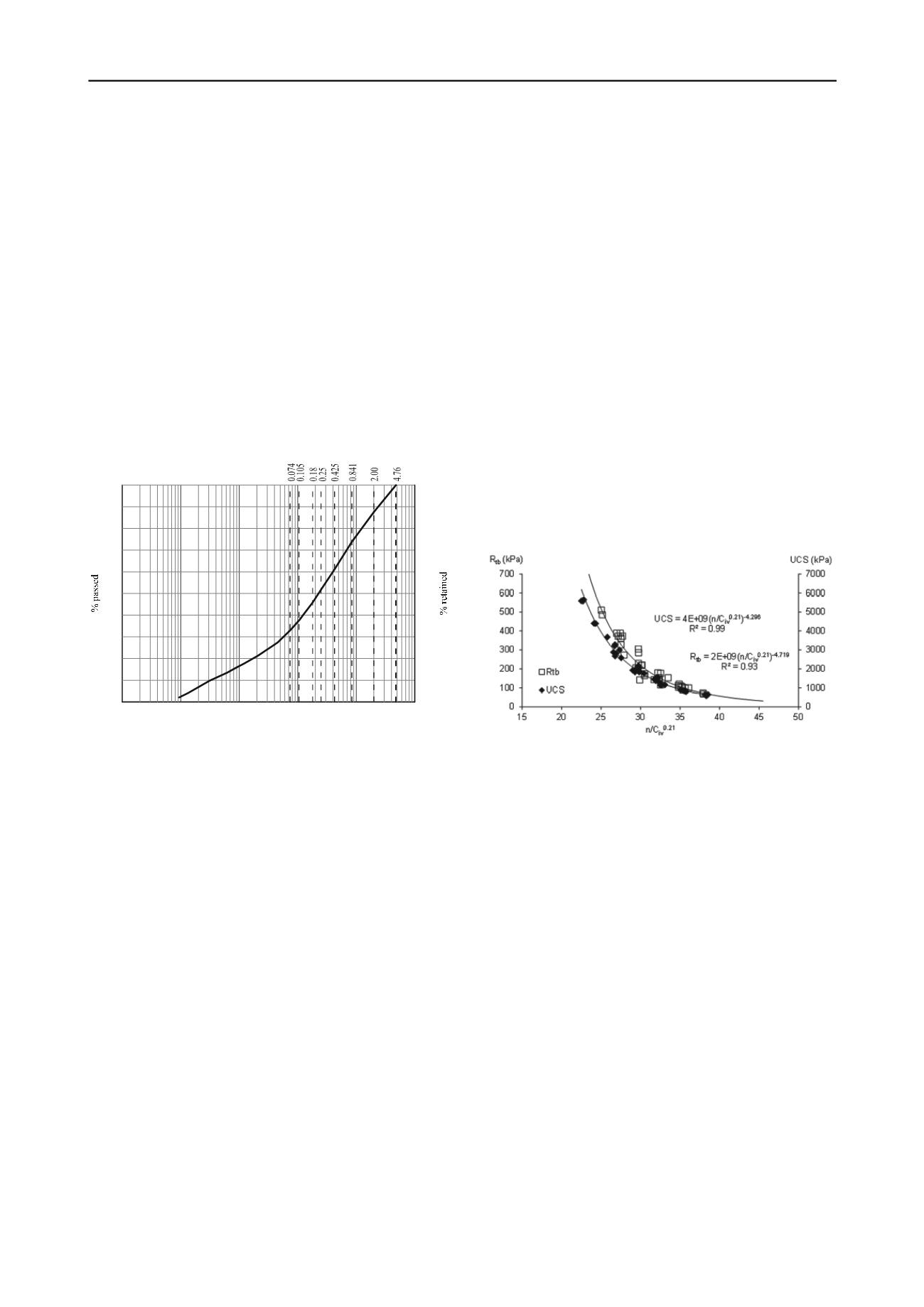

The representation of the unconfined compression strength

(UCS) and the ratio of porosity to the volumetric cement

content (n/C

iv

) revealed that some adjustment was needed and

therefore, an exponent was added to C

iv

. This exponent was

defined as the value that provides the best correlation

coefficient with the data, which, for this material, was found to

be 0.21

–

Eq. (1).

UCS (kPa) = 4E+09 (n/C

iv

0.21

)

-4.296

(1)

This exponent seems to depend on the type of soil as other

authors have found different coefficients when working with

different soils (Consoli et al., 2007, 2011): an exponent of 0.28

was found in a residual soil from sandstone (Botucatu soil),

while a value of 1.0 was found in an uniform sand (Osorio

sand). Based on this parameter, named adjusted porosity/cement

ratio (n/C

iv

0.21

), the results of different tests were analysed.

1.1

Tensile strength

Taking into account the possibility of shrinkage in cemented

materials, the evaluation of the tensile strength is of utmost

importance. In that sense, indirect tensile tests following the

standard EN 13286-42 (CEN, 2003) were performed on similar

specimens whose results were plotted against n/C

iv

0.21

for which

Eq. (2) was obtained,

R

tb

(kPa) = 2E+09 (n/C

iv

0.21

)

-4.719

(2)

The results showed that the indirect tensile strength (R

tb

) was

about 11% of the UCS. In Figure 2 both R

tb

and UCS are

plotted against n/C

iv

0.21

in different scales for comparison. It is

clear that both trends are very similar (except for the absolute

values) corroborating the convenience of the adjusted

porosity/cement ratio.

In Consoli et al. (2011), where the data from these tests is

plotted together with data from other two soils, it is shown that

for the three soils a decrease in porosity promotes an increase in

the tensile strength as a consequence of the higher number of

contact points between particles which improves the

cementation. Also for the other two soils, a unique correlation

was found between the adjusted porosity/cement ratio and the

indirect tensile strength, the exponent of the ratio depending on

the soil.

Figure 2. Indirect tensile strength and unconfined compression strength

against the adjusted porosity/cement ratio

3.2 Triaxial tests

Drained triaxial compression tests were performed over soil-

cement specimens, which were moulded to have two different

adjusted porosity/cement ratios (n/C

iv

0.21

=36 and 29)

corresponding respectively to UCS of 800 kPa and 2000 kPa.

For these ratios, two moulding conditions were defined

characterized by cement content and dry unit weight while the

water content remains constant and equal to 12%. For the first

ratio (n/C

iv

0.21

= 36), 2 and 4% cement contents were considered

which lead to dry unit weights of 16.7 and 15.4 kN/m

3

,

respectively. For the second ratio (n/C

iv

0.21

= 29) higher strength

was needed, so 5 and 7% of cement contents were assumed with

17.0 and 16.4 kN/m

3

of dry unit weight. The tests were

performed at three different effective confining pressures (30,

80 and 250 kPa) over specimens moulded in four moulding

points, comprising 12 tests (Table 1).

The stress-strain curves (see Figure 3 as an example) clearly

evidence that the specimens with n/C

iv

0.21

=29 have higher peak

deviator stresses than the specimens with n/C

iv

0.21

=36

independently of the cement content. Adding cement to the sand

had the effect of increasing the shear strength by up to five

times for the adjusted porosity/cement ratio of 36 and tenfold

for the adjusted porosity/cement ratio of 29.All specimens

initially compressed, followed by significant dilation, which

was associated to a peak strength, before strain softening. This

is typical of cemented soils, with the maximum rate of dilation

taking place right after the peak strength (Viana da Fonseca

1998). The peak strength corresponds to the onset of significant