2595

Technical Committee 211 /

Comité technique 211

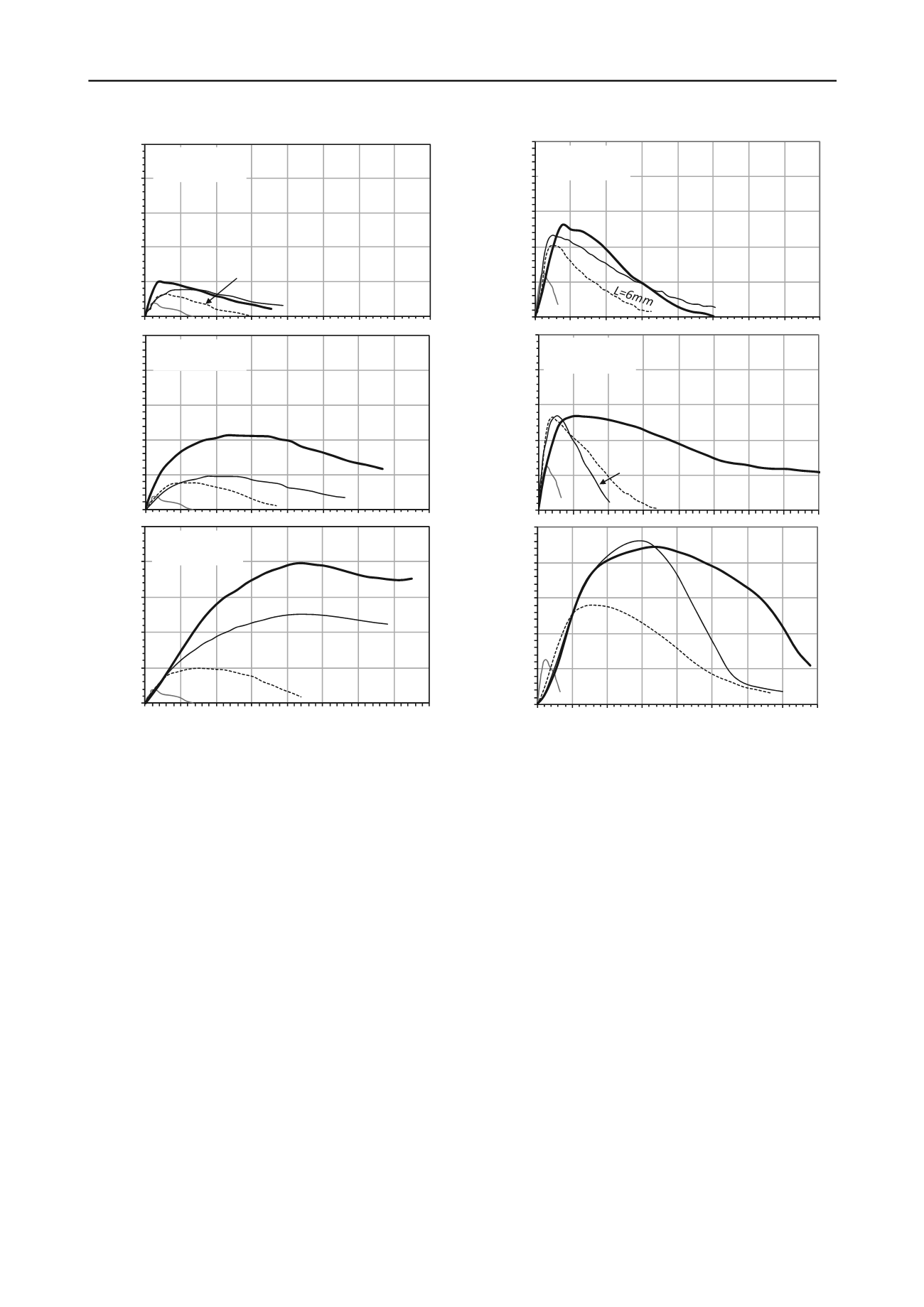

Figure 2. Stress-strain response for cement content of 0.5%.

3.3

Effect of Fiber Content on UCS

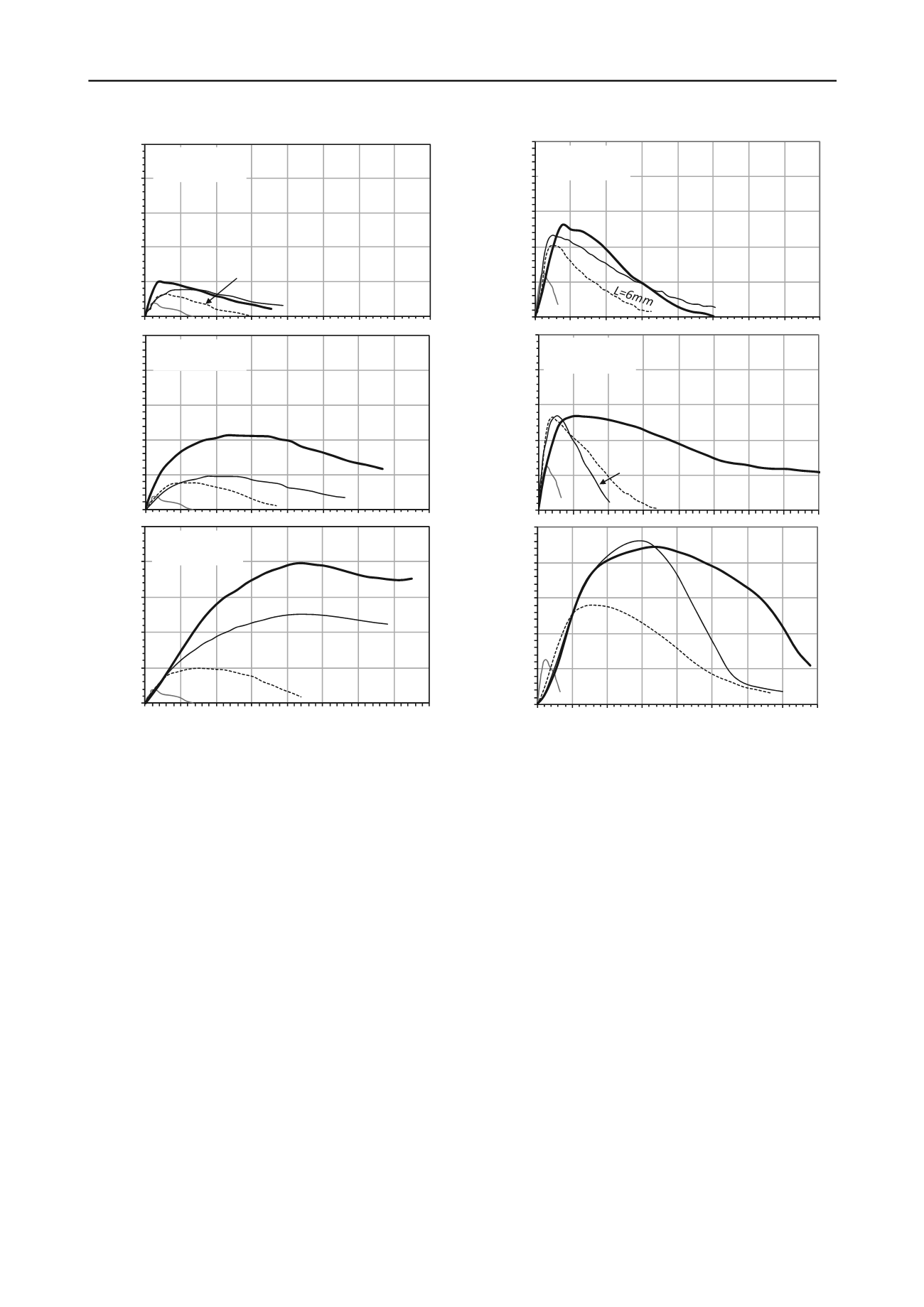

For a given cement content, the stress-strain curves in Figs. 2

and 3 indicate that the unconfined compressive strength

increases as the fiber content increases. The unconfined

compressive strength for each test was computed and plotted as

a function of the fiber content in Figs. 4a and 5a for cement

contents of 0.5% and 1.0%, respectively. For the two cement

contents and for all fiber lengths, results indicate a consistent

increase in the unconfined compressive strength with fiber

content. For a cement content of 0.5%, the UCS increased from

about 15 kPa (no fibers) to about 40 kPa (1.0% fibers) for the

shortest fiber length of 6mm, and from 15 kPa (no fibers) to

about 160 kPa (1.0% fibers) for the longest fiber length of

20mm. For the larger cement content of 1.0%, the UCS

increased from about 50 kPa (no fibers) to about 112 kPa and

178 kPa, for the shortest and longest fibers at 1.0% fiber

content, respectively.

In order to obtain a quantitative measure of the degree of

improvement in the unconfined compressive strength, the ratio

of the UCS with fibers to the UCS without fibers was computed

and plotted versus the fiber content in Figs. 4b and 5b. These

results indicate that the cement content played a significant role

in defining the improvement ratio, with the ratio varying from 2

(smallest fiber content and fiber length) to 10 (largest fiber

content and fiber length) for a cement ratio of 0.5%, and from

about 2 to 4 for the larger cement ratio of 1.0%.

0

40

80

120

160

200

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0

Compressive Stress (kPa)

Axial Strain (%)

L=12mm

L=20mm

No Fibers

1.0% Cement

0.25% Fibers

0

40

80

120

160

200

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0

Compressive Stress (kPa)

Axial Strain (%)

L=6mm

L=12mm

L=20mm

No Fibers

1.0% Cement

0.50% Fibers

0

40

80

120

160

200

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0

Compressive Stress (kPa)

Axial Strain (%)

L=6mm

L=12mm

L=20mm

No Fibers

1.0% Cement

1.0% Fibers

0

40

80

120

160

200

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0

Compressive Stress (kPa)

Axial Strain (%)

0.50% Cement

0.25% Fibers

L=20mm

L=12mm

L=6mm

0

40

80

120

160

200

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0

Compressive Stress (kPa)

Axial Strain (%)

0.50% Cement

0.50% Fibers

L=6mm

L=12mm

L=20mm

No Fibers

0

40

80

120

160

200

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0

Compressive Stress (kPa)

Axial Strain (%)

0.50% Cement

1.0% Fibers

No Fibers

L=6mm

L=12mm

L=20mm

Figure 3. Stress-strain response for cement content of 1.0%.

3.4

Effect of Fiber Length on UCS

The effect of the fiber length on the stress-strain response and

on the improvement in the UCS is evident in Figs. 2 to 5 and is

found to be dependent on the cement content. For a cement

content of 0.5%, as the fiber length increases, the unconfined

compressive strength increases and the strain at failure

increases, indicating improved ductility. The effect of fiber

length was found to be more evident at higher fiber contents

compared to lower fiber contents. For example, for the small

fiber content of 0.25%, the improvement ratio in the UCS

increased slightly from 1.7 to 2.6 (for fiber length of 6mm and

20mm) compared to the dramatic increase from 2.6 to 10.6 (for

fiber length of 6mm and 20mm) for the larger fiber content of

1.0%.

For the larger cement content of 1.0%, the effect of fiber

length on the unconfined compressive strength becomes

smaller. For the smaller fiber contents of 0.25% and 0.5%, the

difference in the measured values of the UCS is relatively

insignificant, with improvement ratios varying in the narrow

range of 1.6 to 2.0 (fiber content of 0.25%) and 2.1 to 2.15

(fiber content of 0.50%) for the shortest and longest fibers,

respectively. For the largest fiber content of 1.0%, the

improvement ratio increases from 2.2 to 3.7, as the fiber length

increases from 6mm to 20mm.