1902

Proceedings of the 18t

h

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

.

4

3.5m

1.7m

7.8m

S3

S2

S1

2.0m

3.5m

0.5× 4=2.0m

CPT

Cuttings of slope

﴾

Failure occurred

after S7

﴿

S4

2.0m

30°

60°

S6

S7

S5

70°

75°

1.0m

Tarpaulin

4m

Concrete

wall

Cutting marks

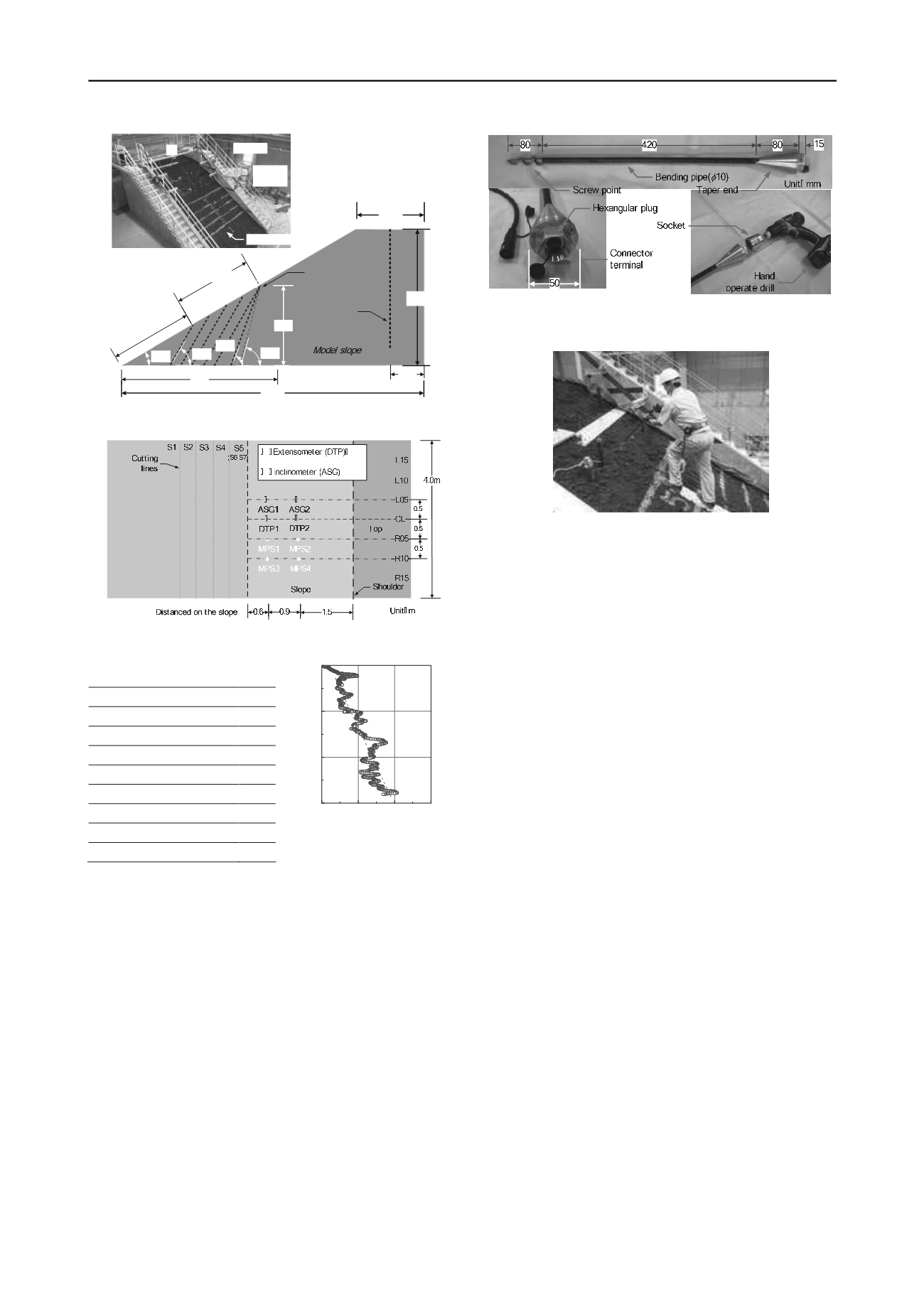

Figure 1. A profile view of model slope.

Figure 3. A plane view to show the installed position of sensors

0

500

1000

1500

- 3

- 2

- 1

0

Depth

d

(m)

Cone penetration resistance

q

c

(kN/ m

2

)

Figure 2. Relationship between

cone penetration resistance and

depth from the top of slope.

Seven steps of cuttings were carried out by construction

machinery in the toe of slope. 60 degrees angle in the cuttings

was performed from S1 to S5 that was 0.5m long from front to

back as shown in Figure 1. As for S6 and S7, the cutting angle

was increased to 70 degrees and 75 degrees, respectively. Thirty

minutes interval time between the steps was provided to observe

the movement of the slopes.

3.2

Installation of sensors

Three kinds of sensors, extensometers (DTP), inclinometers

(ASG), and compact shear strain meters (MPS), were installed

to measure the movement of the slope during the test. Figure 3

shows the installed positions of the sensors. Two sets of DTP

were installed to measure increment of the displacement

d

by

giving 0.9m interval at the center column (CL). Sensor units of

DTP were set on a beam bridging over the retaining walls while

extended wires were connected to pegs on the slope.

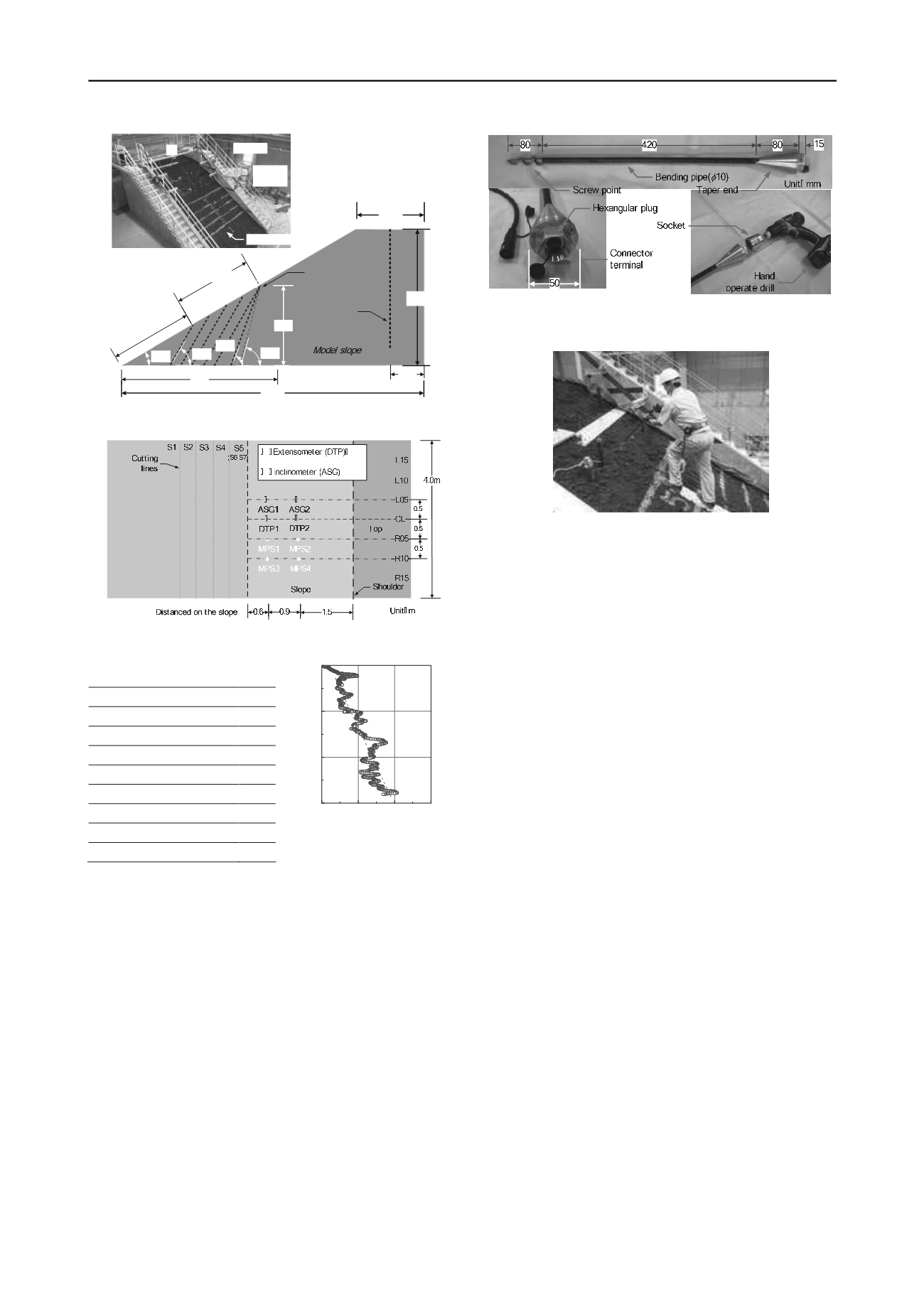

Figure 5. Shape and structure of a developed compact shear strain meter

(MPS).

Photo 1. Installation of MPS

Two sets of ASG were installed to measure an increment of

the angle of inclination

a

on the surface at the column of L05 at

same height as DTP. Four sets of MPS to be explained in the

following section were also installed to measure increment of

the interpreted shear strain

at the columns of both R05 and

R10 in the same manner as the installation in ASG.

4 MESUREMENT OF SHEAR STRAIN IN THE

SHALLOW SECTION

4.1

Development of compact shear strain meter

A compact shear strain meter called MPS was developed to

measure the shear strain in the shallow section of slopes

(Tamate. 2010). MPS made of compact size rod 0.6m in length,

10mm in diameter, and 3.6N in weight is shown in Figure 4. A

screw point of 80mm in length attached in the lower end

enables to penetrate the unit into the ground without pre-boring.

A taper end of 100mm in length is used to provide a lateral

compression to the surrounding soil so that MPS reacts to the

slope movement by its bending deformation. A connector

terminal for data transmission composed of 7 poles is mounted

at the center of a hexangular plug for rotational installation by a

hand drill.

A bending pipe of 420mm in length is positioned between the

screw point and the taper end. Four strain gages are pasted on

both front and back of the pipe so that the electrical output

increases with the bending deformation. A heat shrinkable tube

covers the pipe to protect the gages from surrounding soil at

installations. Since duration for the installation was less than 10

seconds, easy and quick installation is available in practice as

shown in Photo 1.

4.2

Basic idea for the monitoring

Figure 5 shows a schematic image of distribution of

displacement and shear strain in the slope. An increment of the

displacements occurs near the slip plane whereas the increment

converges as the distance increases.. Accordingly, major shear

strain develops along the slip plane. However, this study aims to

monitor the shear strain in the shallow section of slopes from

the easily application viewpoint (Tamate et al. 2009). MPS was

developed to measure the small shear strain in the shallow

sections easily.

Table 1.Soil properties of Kanto

loam.

Densityofsoilparticles

s

(g/cm

3

) 2.759

Sand (0.075

~

2mm) % 6.2

Silt (0.005

~

0.075mm) % 45.3

Clay (Diameter<0.005mm) % 48.5

Liquid limit

w

L

(%)

158.3

Plastic limit

w

p

(%)

97.7

Plasticity index

I

p

60.6

Dry density

dmax

(g/cm

3

)

0.665

Optimumwatercontent

w

opt

(%) 102.0