1894

Proceedings of the 18t

h

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Analysis of the materials of the investigations shows that

at the moment 60% of gravity sewage tunnels and 80% of

pressure sewage tunnels require repairs and sanitation.

Instrumental probing (with geological radar) shows that 70-

75% of inner surface of pumping plants wells and sewage

tunnels have continuity violation and cracks which require

strengthening of construct and renewal of waterproof shell.

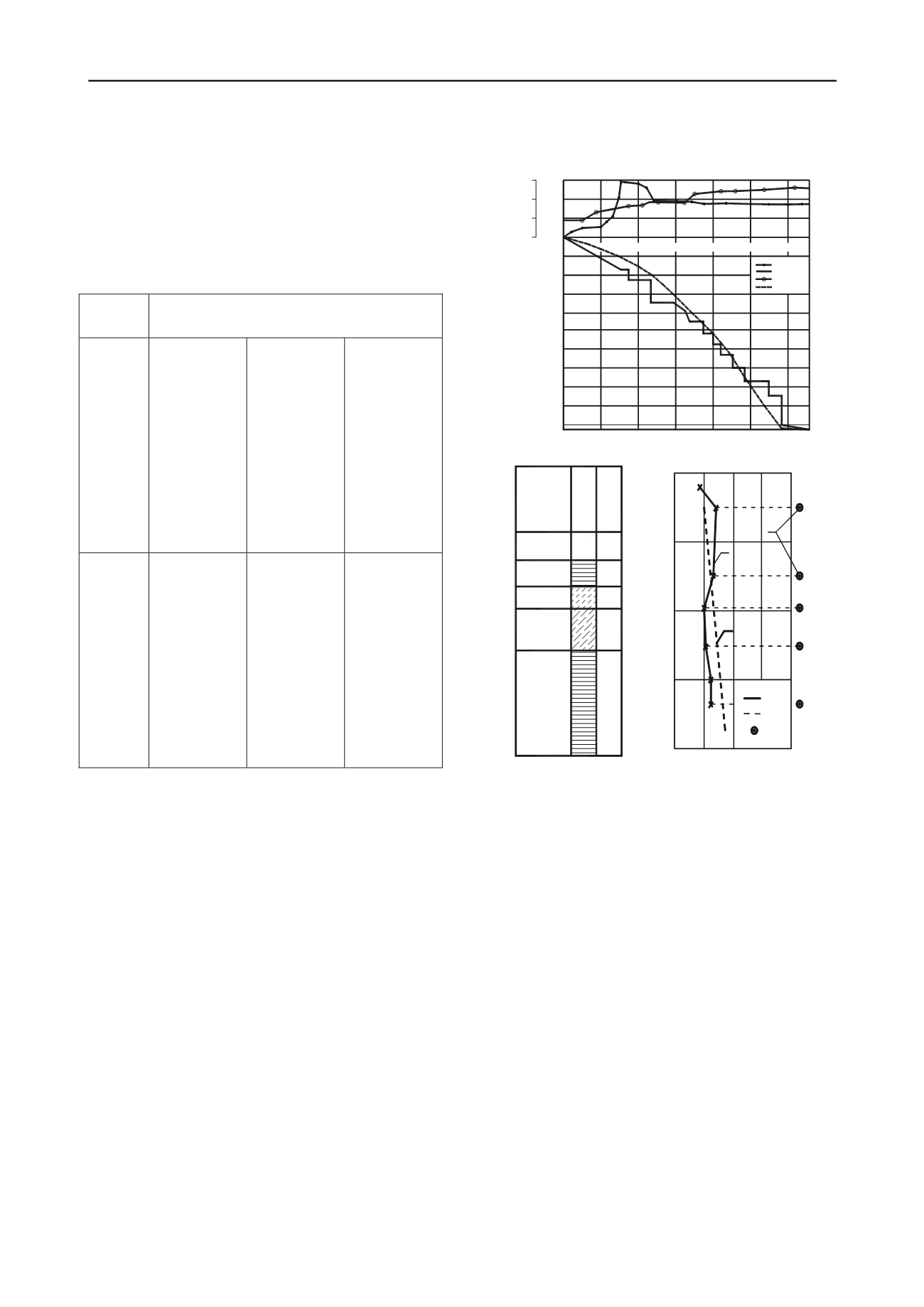

Table 2. The list of defects typical for the long-term operated

(more than 30-45 years) deep pumping plants and tunnel collectors.

Location

of

the

defect

Description and photo of the defect

Sunk

wells

walls

Up to -25÷30m

marks.

On

some

sections of sunk

well

walls

there’s leakage

through knots.

In the knots

area

there’s

leakage

of

concrete

corrosion.

Defects are of

repetitive

nature.

-30 to -40÷45m

marks.

On the surface

of the wall

there’re marks

of

intense

leakage through

the

cracks.

Defects are of

mass nature. In

the knots area

there’s leakage

of

concrete

corrosion.

More than -45m

marks.

On the surface

of the wall

there’re marks

of

intense

leakage through

the cracks. In

the knots area

there’s leakage

of

concrete

corrosion.

Defects are of

mass nature.

Sewage

tunnels

lining

Tubing lining

shows leakage.

Underground

waters go to the

collector

through cracks

and knots in

solid

ferroconcrete

inside

lining.

There’s leakage

of

concrete

corrosion and

salts.

There’s

a

water-filled

space in the

form of a thin

gap between the

tubing

lining

and the jacket

of

collector.

Defects

are

hidden, can be

found

geological radar

probing

of

collector

facilities.

Solid

ferroconcrete

inner

lining

(jacket)

is

destroyed,

there’s intense

leakage

in

welded seams.

2. ANALYSIS OF FACTORS INFLUENCING THE

SAFETY OF DEEP ENGINEERING STRUCTURES

AND MEASURES FOR THEIR ELIMINATION

2.1 Analysis of monitoring data for the construction of sunk

large pumping plants and of the inspection results after

long term operation

The slotted soil column for construction of sunk wells for

main pumping plants in the conditions of St. Petersburg is

characterized as follows: top part is presented by quaternary

beddings to the depth of 14.0-25.0 meters (middle-density

water-saturated dust sand E=11 MPa, C=0 MPa,

=30

;

laminar silt sandy loam Е=4 MPa, С=0.01 MPa,

=15

;

laminar silt loam, very soft Е=9 MPa, С=0.025 MPa,

=16;

semisolid silt loam with gravel, pebbles Е=14 MPa, С=0.028

MPa,

=28

), lower part is represented by top of positioned

Proterozoic bluestone (Е=19 MPa, С=0.04

0.06 MPa,

=18-

21

).

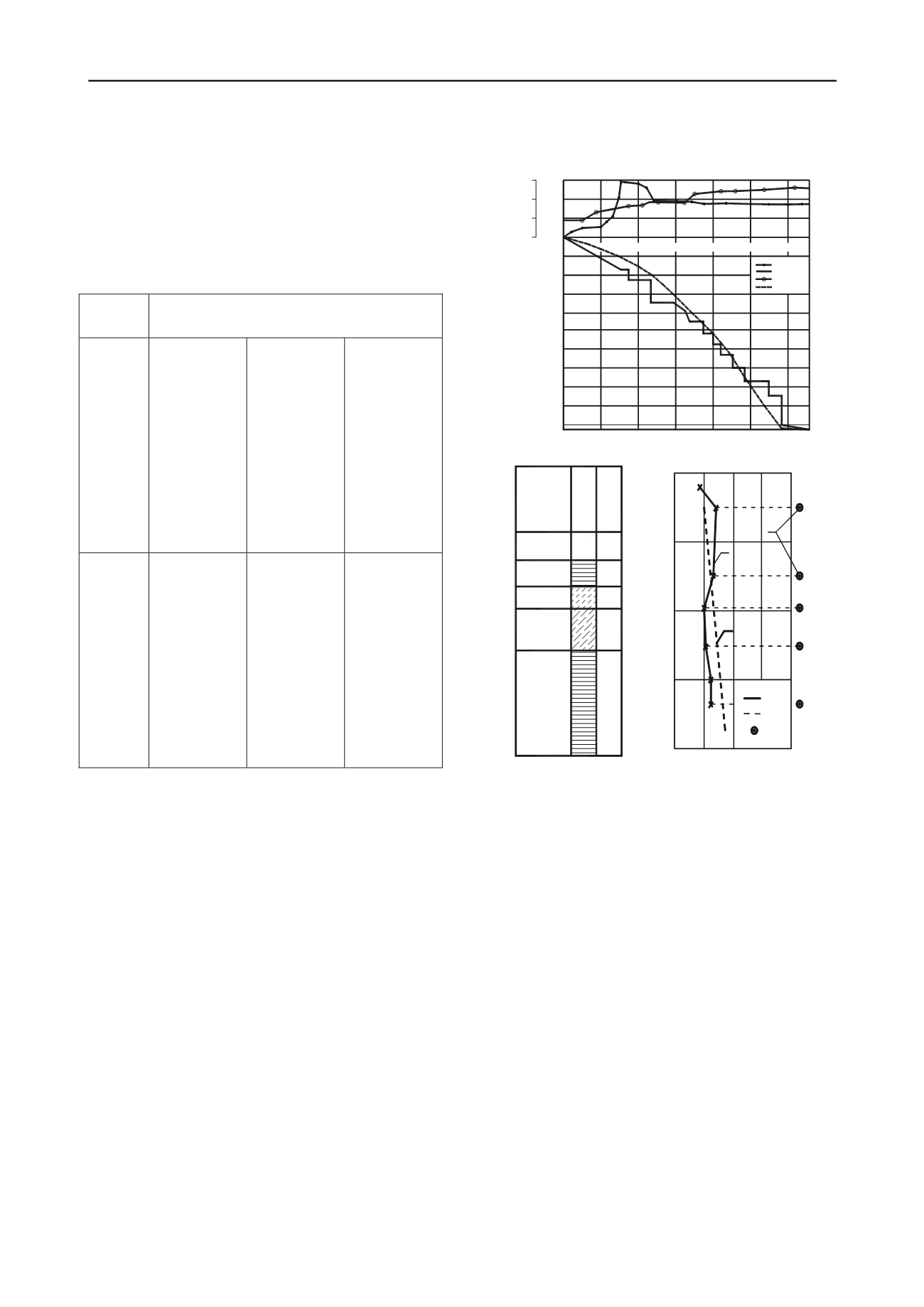

Figure 1 shows the monitoring results for the

construction of a large sunk well using the method of PSTU

(Perminov N.A., Lombas S.V., 2004).

a)

40

30

20

50

10

0,0

м

0,4

0,8

1м

0

25

40

кН *10

5

ия (Н)

4

8

12

16

20

24 мес

П

ения (Т)

родолжительность погруж

Immersion duration (T)

Глубина погружен

1

2

3

4

Weight (G)

Careen (ΔН)

Immersion depth (H)

b) c)

Вид

грунта

т.

на

леват.

глинок

пылеват.

ина

еват.

е

0.2 0.4 0.6 0.8

p (MPa)

5

6

20.00

30.00

40.00

50.00

1.02

0.97

0.83

1.14

1.21

7

- 7

- 6

- 5

Обозначени

Песок

пылева

Гли

пы

Су

Гл

пыл

7,10

5,00

5,10

9,05

25,20

Сугли

пы

нок

леват.

Notations

Type of

soil

dust sand

dust

bluestone

sandy loam

sa

lo

ndy

am

du

bl

st

uestone

Figure 1. The monitoring results for the immersion of a large sunk

well:

a) motiongramm of immersion; b) engineering and geological

conditions; c) monitoring data

1 – diagram of vertical misalignment (careen); 2 – diagram of

immersion; 3 – weigh of the well shell; 4 –ditch bottom; 5,6,7 –

correspondingly, calculated, averaged and peak values of lateral soil

pressure.

The stresses in the reinforcement and concrete were

measured using primary device string type PSAS and PLDS.

To determine the soil pressure membrane load cells with a

range of 0 to 12MPa and measurement error of 5-7% were

used. The measurement was done both in the discrete and

continuous mode using the local electronic switches (LEC),

and data storages (END).

Analysis of monitoring data of large sunk wells with

diameters from 50 to 66m and a depth of immersion of 55 to

71m shows (see Figure 1) that in the process of immersion in

the soils with different strengths and asymmetric structures

deviation from the vertical axis (careen) is observed, with a

shift of the center up to 1.5-1.8 m. In this case, according to

an automated continuous monitoring, as a result of abrupt

landings (breakdowns) stresses in the reinforcement, concrete

and soil pressure may exceed the calculated and the average

values (according to the discrete measurements) 12-15 times.

To estimate the stress-strain state of the well shell with a

sharp landing (breakdown) numerical modeling was

conducted. In the calculations the finite element method

(FEM) and the software package Robot Professional 2010

were used. The calculation is carried out for spatial shell with