1903

Technical Committee 206 /

Comité technique 206

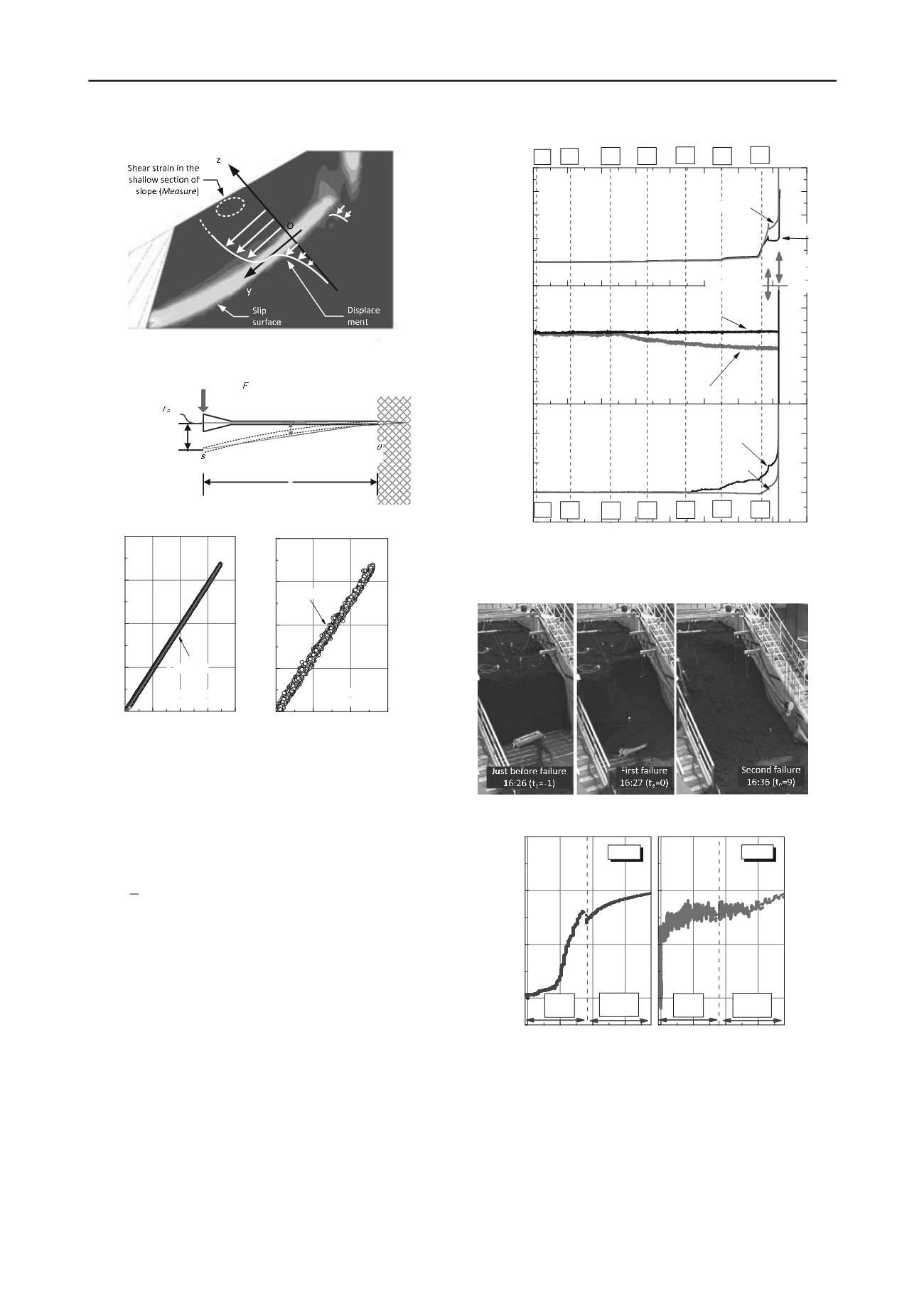

Figure 5. Schematic image of distribution of shear strain at slope failure.

L

Set t l ement

Fi xed end

Load

Out put

I nt erpr et ed shear st rai n

﴾

Negat i ve i n t he di rect i on

﴿

a) Outline of method for calibration of MPS

0.0 0.3 0.6 0.9 1.2

0

200

400

600

800

Out put

r

s

(

)

Interpreted shear strain

(%)

r

s

=653.5

s

Coefficient of

correlation 0.99

0

2

4

6

0

2

4

6

8

Load

F

(N)

Settlement

s

(mm)

F =1.31 s

Coefficient of

correlation 0.99

b) Electrical output

r

s

and interpreted shear strain

c) Load

F

and settlement

s

Figure 6. Stiffness and sensitivity of MPS

A calibration of MPS was carried out to investigate the

relationship between the electrical output from MPS

r

s

(

) and

the interpreted shear strain

(%).

was defined as the ratio of

the settlement

s

to the effective length

L

of MPS as shown in

Equation 1.

100

(%)

L

s

( 1 )

A vertical load

F

was applied to the end of MPS that was

supported by cantilever beam as shown in Figure 6. A clear

linear relationship is obtained between

r

s

and

as well as

between

F

and

s

. Since 653

in

r

s

was output at 1% in

, a

high resolution on the shear strain was confirmed.

5 EXPERIMENTAL ANALYSES ON MOVEMENT IN

SLOPE

5.1

Comparison of reactions by sensors

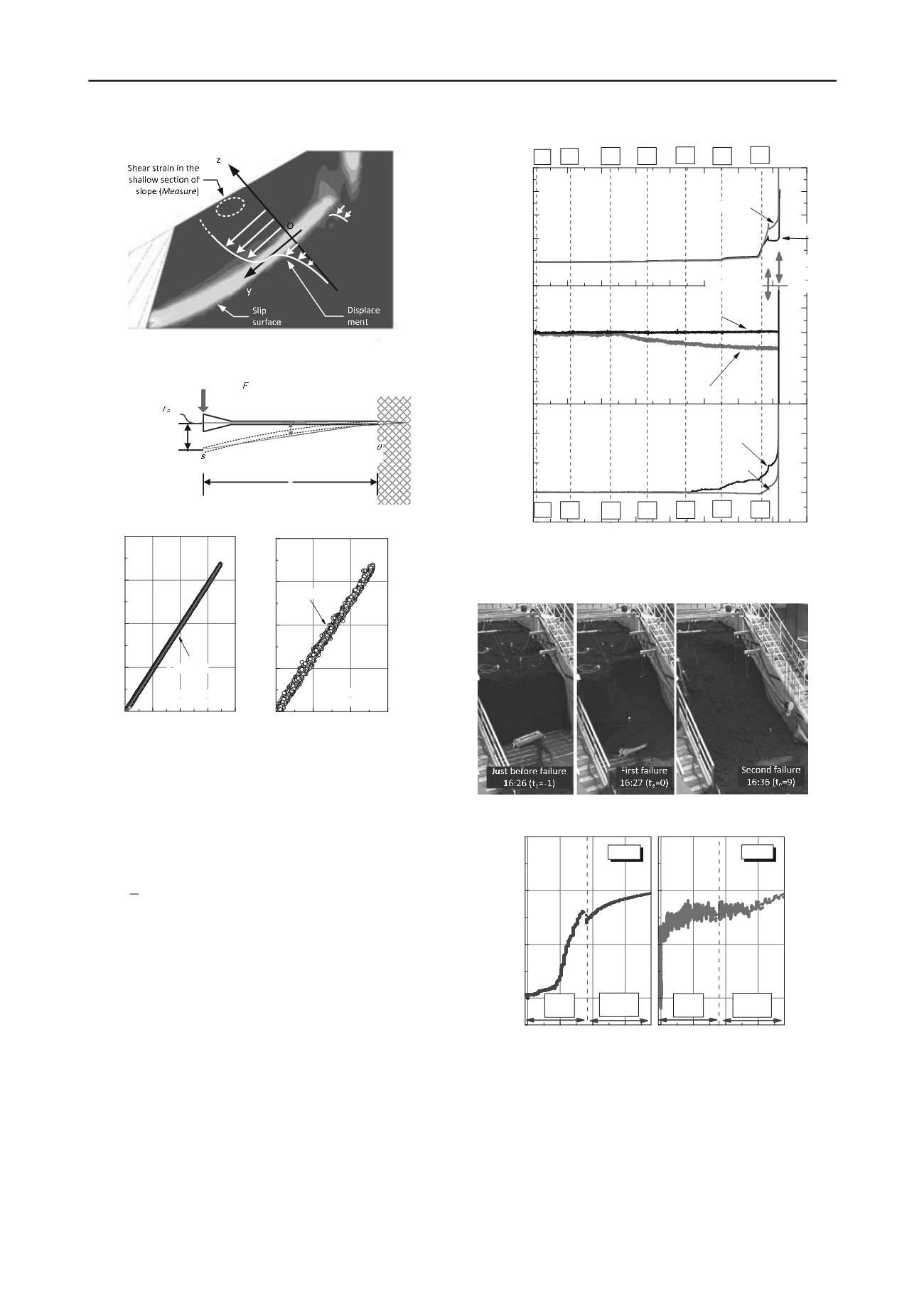

Figure 7 shows the reactions from three kinds of the monitoring

sensors. Horizontal axis means the actual time at the test. The

first cutting (S1) begun at 13:00 and the final cutting (S7) was

completed at 16:20. The slope collapsed twice at16:27 and

16:36. This meant that 7 minutes remained prior to the first

failure and 16 minutes existed up to the second failures after the

completion of S7 as shown in Photo 2. An increase of values

appeared in each curve as reactions to increase of potential risk

of slope failure.

13:00 13:30 14:00 14:30 15:00 15:30 16:00 16:30 17:00

- 10

0

10

20

30

- 2

- 1

0

1

0.2

0.0

- 0.2

- 0.4

- 0.6

- 0.8

DT P1

S4

S3

S2

Displac ement

d

(mm)

T ime

S1

S6

S5

DTP2

S7

ASG2

A ngle of inclinat ion

a

(deg)

ASG1

16:27

First failure

MPS2

Int erpret ed shear st rain

(%)

MPS4

16:36

Second

failure

S1 S2

S3 S4

S5 S6

S7

Figure 7. Comparison of reaction of sensors in the model test

Photo 2.Process of failures in the model slope

0

5

10

15

0.0

- 0.2

- 0.4

- 0.6

Second

failure

Second

failure

First

failure

ASG1

Int erpret ed shear st rain

(%)

Displacement

d

(mm)

MPS4

First

failure

0

5

10

15

0.0

- 0.4

- 0.8

- 1.2

Angle of inclination

a

(deg)

Displacement

d

(mm)

Figure 8. The relationship between the interpreted shear strain

and the

displacement

d

(in left) and the relationship between the angles of

inclination

a

and

d

(in right).

First small increase can be seen at S3 in

and its value

shows the step increase from S3 to S7. After S7, however,

values of

kept on increasing from 16:20 to 16:27. Both MPS2

and MPS4 installed at the upper side of the slope show the same

increase. Both two curves bent at 16:27 when the first failure

occurred. Moreover, values of

were built up again at 16:36 of

the second failure.