1440

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

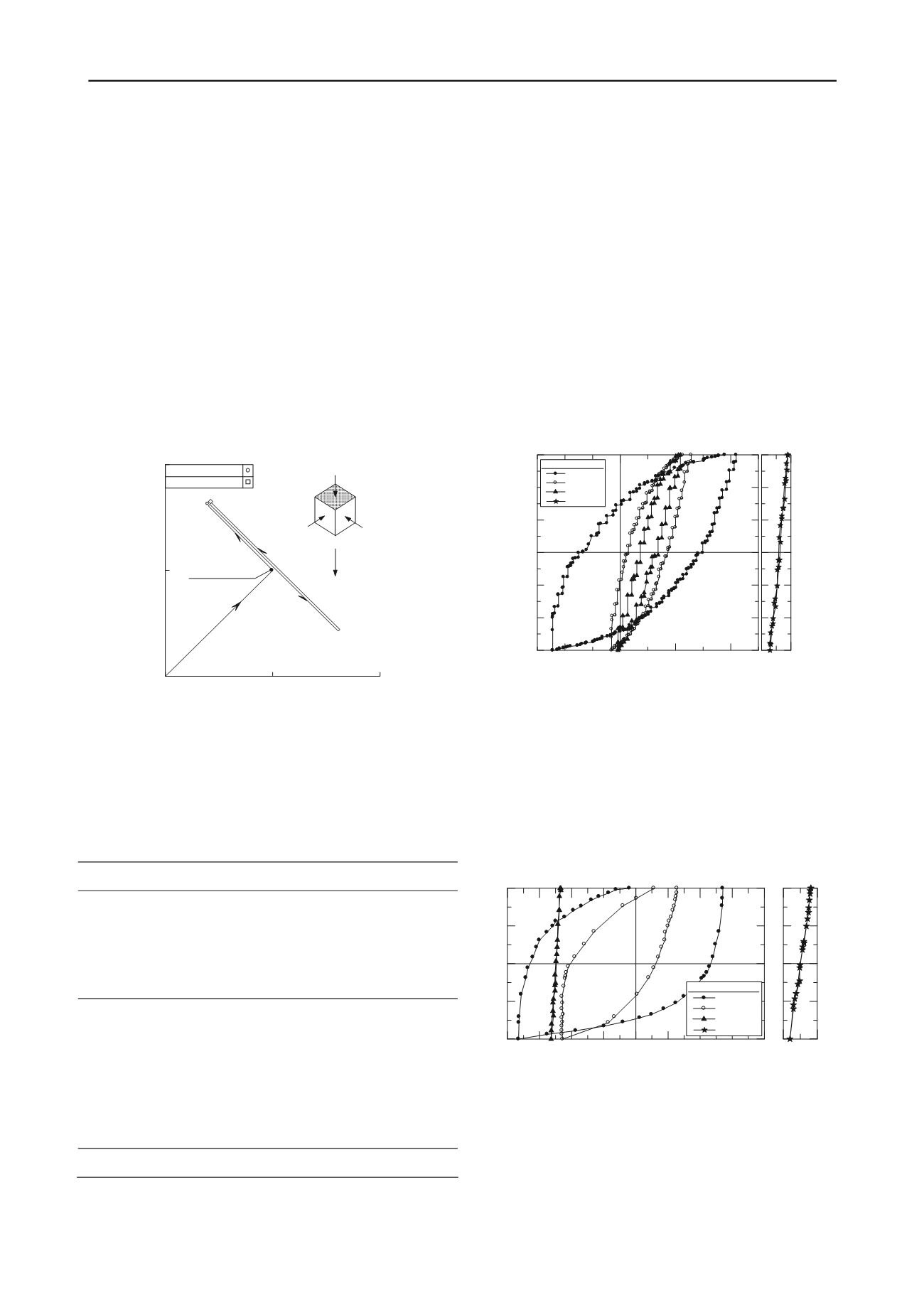

increasing

x

and decreasing

y

whilst the mean biaxial stress,

(

x

+

y

)/2, was held constant at 50 kPa through the test. Typical

stress path for this kind of test are shown in Figure 1.

5 GENERAL EXPERIMENTAL PROCEDURE

Cyclic stress-controlled tests reported in the present research,

performed on dense and loose sand. Fluctuating stresses,

varying between principal stress ratios R

1max

=

x

/

y

and

R

2max

=

y

/

x

(where R

1max

=R

2max

), were imposed on sand

samples until a repeating state of strain was achieved and no

further significant volumetric change was observed (Tests

NDS50-1 and NLS50-2). The peak stress ratios were then

increased and the cyclic stressing repeated. This procedure was

repeated several times. The tests were terminated when the

imposition of a higher stress ratio caused the sand to exhibit

softening behavior which eventually led to a

run away

failure.

Table 1 summarizes the test conditions and program.

0

50

100

x

0

50

100

y

(kPa)

B

D

A

C

Commencing the test

Initial monotonic loading

Start of the first cycle

End of the first cycle

R

2max

y

x

x

y

R

1max

x

y

= =50 kPa

y

y

x

x

Depositon direction

z

z

, =0

(kPa)

=R

2max

R

1max

Figure 1. Stress path for cyclic stress controlled tests

6 TEST RESULTS

Following sections describe the behavior of loose and dense

sand including stress strain characteristics, volume change

trends, stiffening phenomenon and shear modulus evaluation.

Table 1. Test numbers and initial conditions of the cyclic tests; 90

hanges of principal stress direction.

c

Test Number

e

0

No of total cycles Principal stress ratio R

max

(Number of cycles)

D-290

0.52

290

4.00 (50)

4.33 (50)

4.71 (50)

5.15 (50)

5.67 (50)

6.27 (30)

7.00 (10)

L-433

0.72

433

2.33 (100)

3.00 (25)

3.44 (25)

3.71 (40)

4.00 (40)

4.33 (60)

4.71 (60)

5.06 (70)

5.25 (10)

5.45 (3)

1

The bracket indicates the number of cycles performed at a given stress ratio R

max

where R

max

is the maximum stress ratio during each stage of the tes

6.1 Stress strain behavior

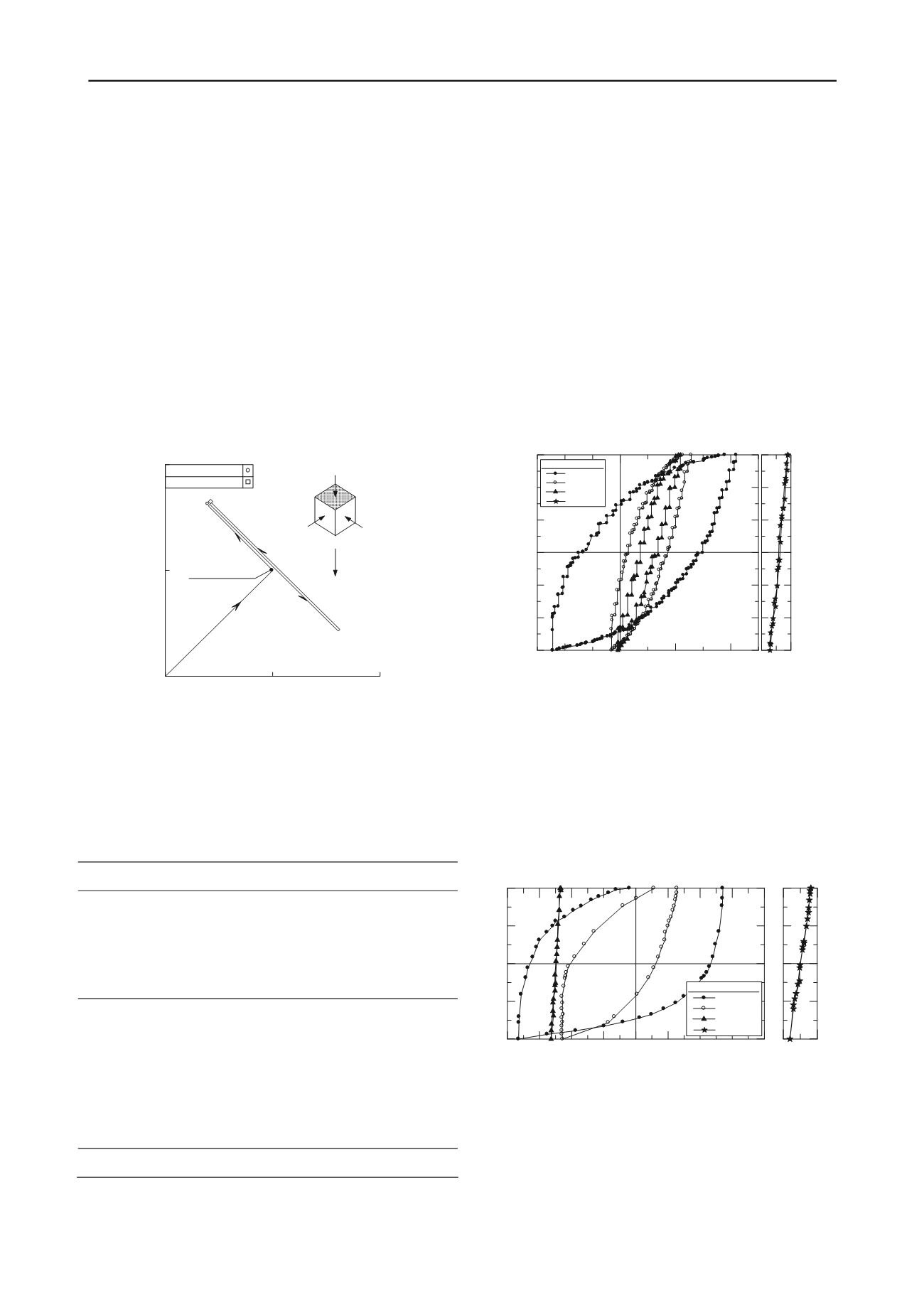

In the course of cyclic stress loading during the first few cycles,

sand exhibits significant plastic deformation accompanied by

open hysteresis loops. Subsequent cycles give less plastic strain

and the loops appear nearly closed, implying the development

of a repeating state.

Dense Sand

: Figure 2 illustrates the hysteresis loops for dense

sand (for cycles 1, 5, 10, 15, and 50) in which the sand sample

was subject to cyclic stressing at different maximum principal

stress ratios from R

max

=4 to R

max

=7. It is worth mentioning that

the test results are shown only for R

max

=4. The Figure shows

that during the first few cycles the hysteresis loops are

open

and

after about 15 cycles the loops appear nearly closed. Further

cyclic stressing led to a progressive stiffening of the material

and resulted in apparent

elastic

behavior in which stress-strain

curves follow the same path during unloading and reloading, i.e.

the area within the hysteresis loop which represents the amount

of dissipated energy during a cycle tends to zero.

-0.5

0

0.5

1

s

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

(Shear strain)%

x

y

x

y

0 0.25

s

t/s=

Test no. : N-290

Cycle 1

Cycle 5

Cycle 10

Cycle 50

Figure 2. Hysteresis loops for dense sand (test No. N-290)

Loose Sand

: The hysteresis loops for loose sand (Test L-430)

in which the principal stress ratio, R

max

varies between 2.33 and

5.45 are shown in Figure 3. The first cycle, in comparison with

10

th

cycle, produced a large hysteresis loop and a huge amount

of unrecoverable strain. Again, repeated cyclic stressing caused

sand to attain an elastic stress-strain response during unloading

and reloading. It is clear that after certain of cycles, say e.g. 20,

further cyclic stressing has no significant influence on the

elastic behavior of material, i.e. no change in shear modulus

will be observed.

-2 -1.5 -1 -0.5 0 0.5 1 1.5 2

s

-0.4

-0.2

0

0.2

0.4

(Shear strain)%

x

y

x

y

-1.5 -1.3

s

t/s=

Test no. : L-430

Cycle 1

Cycle 10

Cycle 50

Cycle 100

Figure 3. Hysteresis loops for Loose sand (test No. L-430)

6.2 Overall Volume Change Behavior

When dense or loose sand samples are subjected to cyclic

stressing at constant stress ratio amplitude, irrecoverable or

plastic strain during each successive cycle tends to reduce with

increasing number of cycles until the induced shear strain over a

cycle remains roughly constant, implying that elastic response

dominates. However, the magnitudes of volume change after

100 cycles are considerably different for the dense and loose