1442

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

290 300 310 320 330 340 350 360 370 380 390 400 410 420 430 440

No. of cycles

0

1

2

3

4

5

s

0

2

4

6

8

10

v

(%)

290 300 310 320 330 340 350 360 370 380 390 400 410 420 430 440

R

max

=4.71

R

max

=5.25

(%)

(d)

Test no. : L-433

Volumetric strain

Shear strain

R

max

=5.061

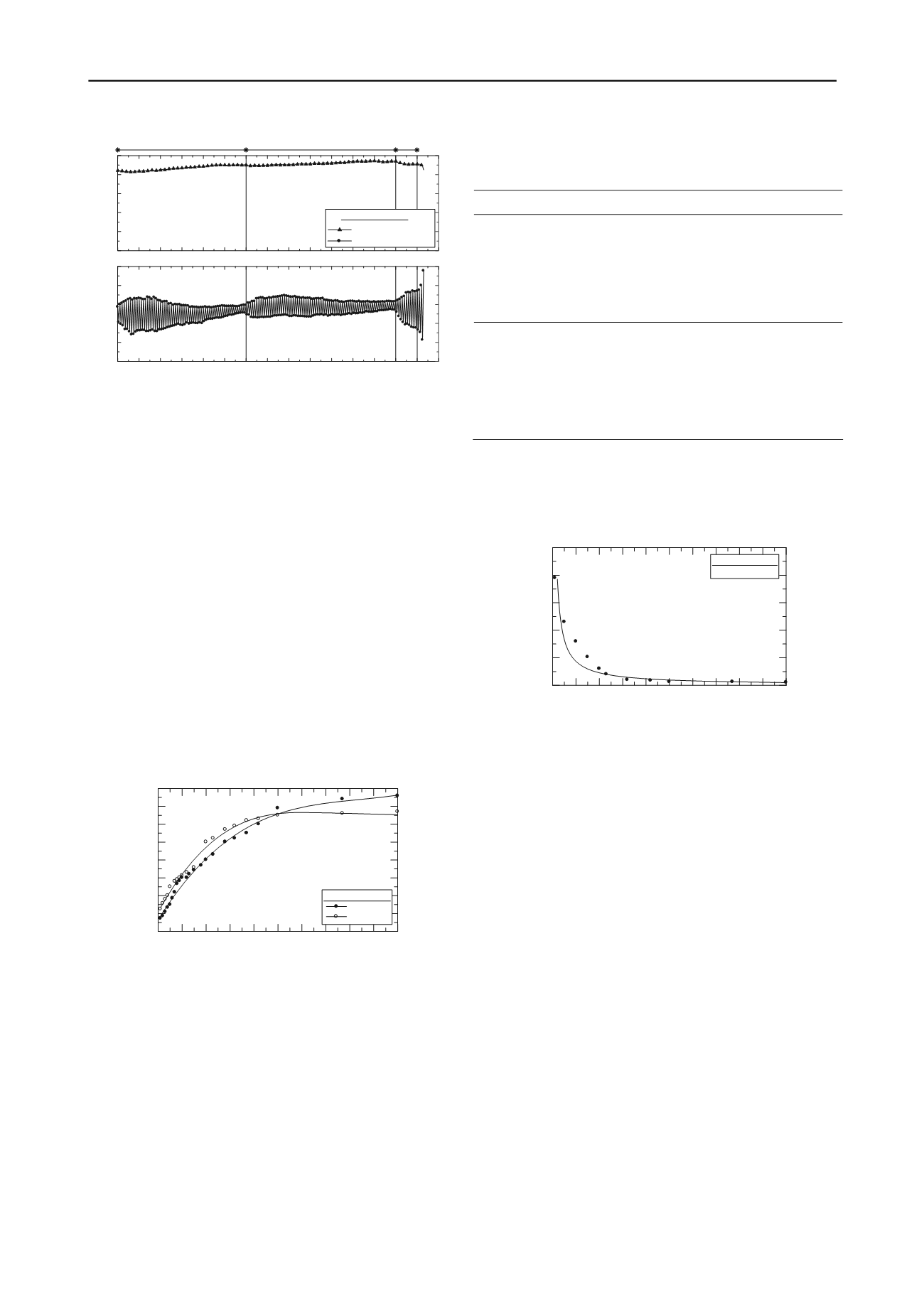

Figure 5. (Continued)

The initial peak stress ratio for the loose sand, Figure 5, started

at t/s=0.40 (R

max

=2.33) in order to prevent premature failure

prior to densification. When sans attains a form of elastic

behavior, R

max

was again increased. It is clear that even at high

stress ratio (R

max

=5.061), the sand tends to reach a steady state.

6.4 Evaluation of shear modulus and damping ratio

Most experimental investigations have implied that the shear

modulus-shear strain relations are mainly affected by voids ratio

and mean confining stress (e.g. Alarcon-Guzman et al, 1989).

Sand under cyclic stressing exhibits non-linear hysteretic stress-

strain behavior. The equivalent linear shear modulus, G, can be

defined by the slope of the chord passing through the ends of

hysteresis loop. As mentioned earlier after many cycles the open

stress-strain hysteresis loop transforms almost into a unique line

during reloading and unloading (Figures 4 and 5). It is evident

with increasing number of cycles the hysteresis loop of stress-

strain becomes gradually narrower and the line whose slope

shows the equivalent shear modulus cannot be separated from a

single stress-strain path during unloading and reloading. This

implies that the sand essentially behaves elastically.

0 10 20 30 40 50 60 70 80 90 100

No. of cycles

0

10

20

30

40

50

60

70

80

Shear modulus (GPa)

Test No.: D-290

R =4

R =4.33

max

max

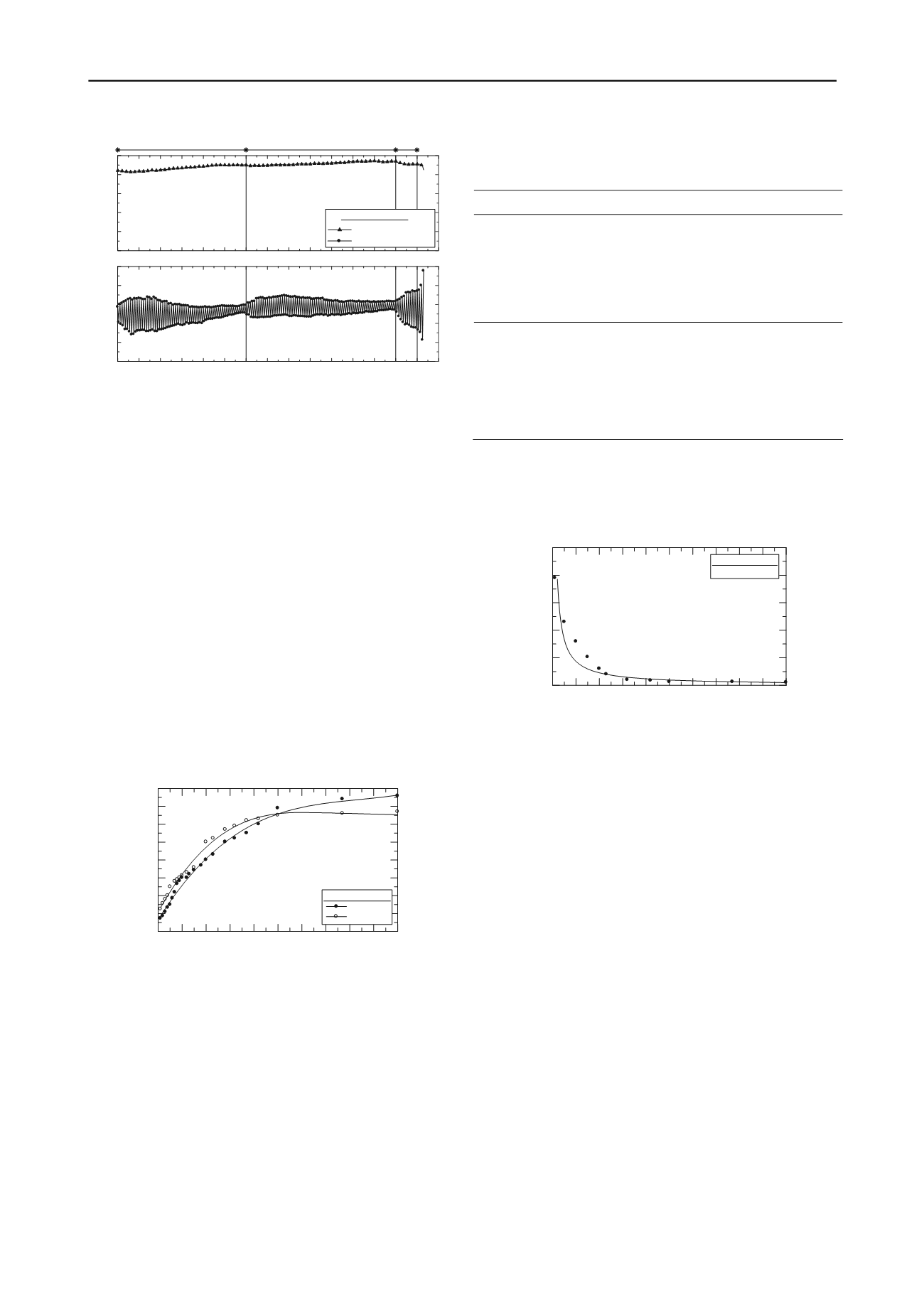

Figure 6. Variation of shear modulus with number of cycles

Shown in Figure 6 are the variations of shear modulus with

number of cycles. It is clear that after many cycles the

magnitude of shear modulus tends to remain constant, implying

an elastic behavior. The following table summarizes the

magnitudes of shear modulus as evaluated after several cycles at

each of eight different stress ratios. The derived magnitudes of

shear modulus for dense test, indicate that for all stress ratios

below R

max

=5.15 the sand attains a form of elastic deformation

as the number of cycles approaches 50. An average magnitude

of G=70 MPa for all stress levels below R=5.15 implies that if

sand behaves elastically at any maximum principal stress ratio,

R

max

5.15, then there exists a unique value for shear modulus

which is independent from the stress level and current voids

ratio. However, when the maximum stress ratio is as high as

R

max

=5.67, the magnitude of G=32.9 MPa, is considerable lower

than the average magnitude, G=70 MPa, obtained earlier.

Table 2. Evaluation of shear modulus for dense and loose sand at

several peak stress ratios.

Test Number

R

max

No of cycle

G (GPa)

D-290

4.00

4.33

4.71

5.15

5.67

6.27

7.00

50

100

150

200

250

270

275

75.8

67.8

69.3

71.2

32.9

4.53

4.52

L-433

2.33

3.00

3.44

3.71

4.00

4.33

4.71

5.06

100

124

149

189

229

289

349

419

45.2

38.7

20.0

35.2

30.8

28.8

36.7

34.7

The damping ratio for dense test is shown in Figure 7. The

damping ratio decreases with increasing number of cycles. After

a large number of cycles, damping ratio tends to becomes zero,

again indicating an elastic behavior.

0 10 20 30 40 50 60 70 80 90 100

No. of cycles

0

10

20

30

40

50

Damping ratio (%)

Test No.: D-290

R = 4

max

Figure 7. Variation of shear modulus with number of cycles..

7 CONCLUSIONS

The following points have been raised in this research:

When sand is subjected to cyclic stressing between two equal

peak stress ratios, the sand particles arrange themselves to resist

the directional loading.

Ideally true elastic response can only be achieved when the soil

reaches its densest possible state. However, a strong induced

structure may give the same shear modulus even though the soil

is not at densest state.

There is a unique stress ratio below which cyclic stressing

causes sand to attain an elastic state and above it cyclic stressing

results in a softening response which eventually leads to a

run

away

failure.

8 REFERENCES

Abdul Lahil B. M., Cheung Robert S. L., Mizanur M. R. 2010. Cyclic

instability behavior of sand-silt mixture under partial cyclic reversal

loading,

Recent Advances in Geotechnical Earthquake and Soil

dynamics Symposium

, San Diego, California.

Alarcon-Guzman A., Chameau J. L., Leonards G.A., Frost J. D., 1989.

Shear modulus and cyclic undrained behaviour of sands

,

Soils and

Foundations

, Vol. 29, No. 4, pp. 105-119

Huang Y., Huang A., Kuo Y. C. and Tsai M. 2004. A laboratory study

on the undrained strength of a silty sand from Central Western

Taiwan,

Soil Dynamics and Earthquake Engineering

24, 733-743.

Sitharam T. G., Govinda Raju L., Srinivasa Murthy B.R. 2004. Cyclic

and monotonic undrained shear response of silty sand from bhuj

region in india,

ISET Journal of Earthquake Technology, Vol. 41,

No. 2-4, pp. 249-260

Springman, S. & Norrish, A., (1995), "

Integral bridges - Researches'

viewpoint

", The University of Cambridge.