1436

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

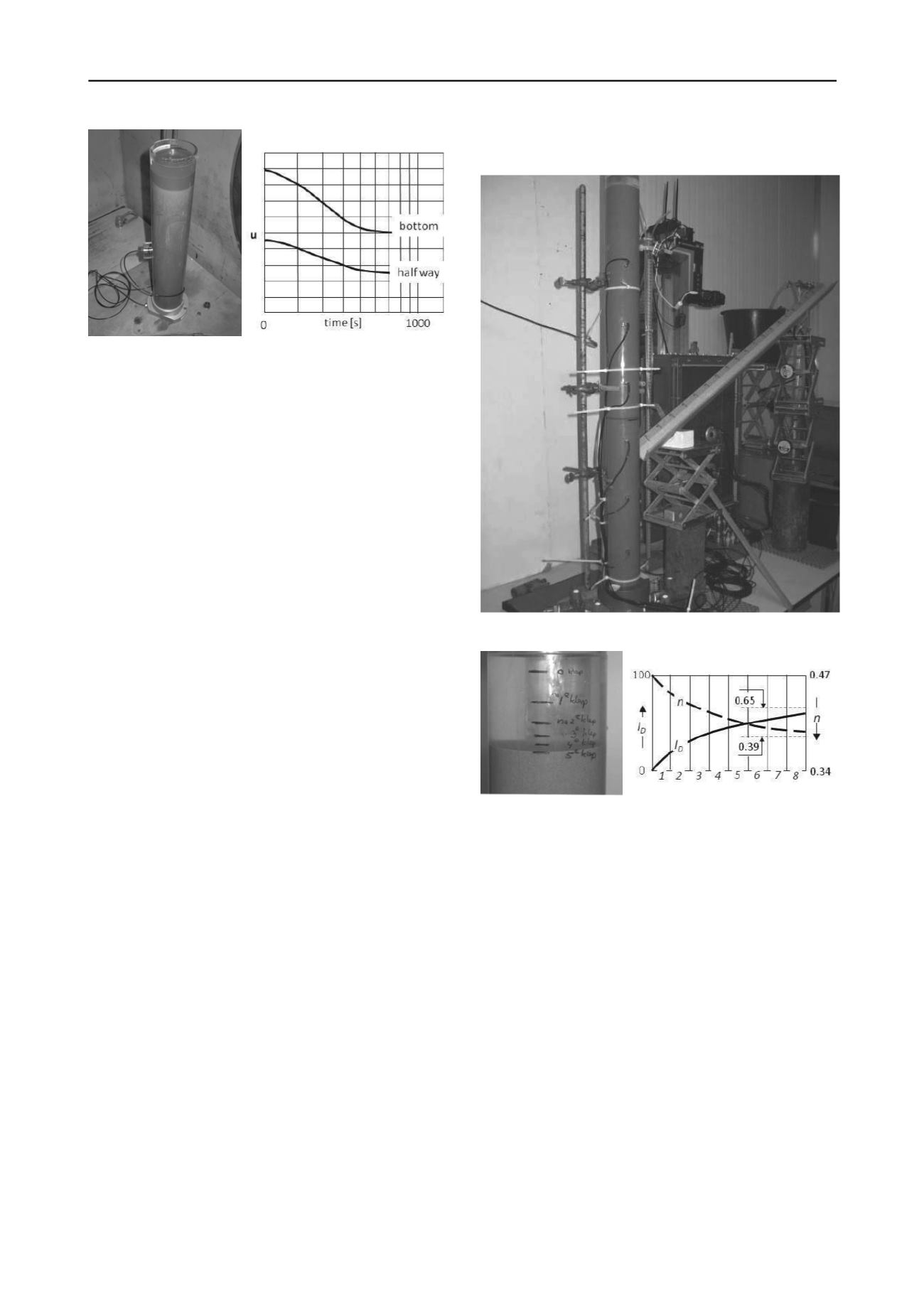

Figure 1a. The test setup Figure 1b. A typical test result

Remarkably, in the early stage of sedimentation the mud

weight causes high excess pore pressures everywhere, nearly

two times the hydrostatic pressure, see Figure 1b. A typical test

shows a maximum pore pressure gradient of 18.8 kPa/m, at the

beginning, representing a mud weight of 18.8 kN/m

3

. The

induced excess pressures dissipate in a way similarly to

hindered sedimentation and consolidation, as described by Pane

& Shiffman (1985), including Kynch's theory. Although the

process locally is highly nonlinear, the period of sedimentation

is about proportional to the square of the dissipation path.

Therefore, we could define a global sedimentation coefficient,

which attains the following value for this material:

s

v

=

(0.5)

2

/7x60

0.6 10

-3

m

2

/s. In the field the sedimentation time

can be roughly obtained with this coefficient for a similar

material of thickness

h

reaching full sedimentation, by using

concepts of the consolidation theory, such as

t

= 2

h

2

/

s

v

.

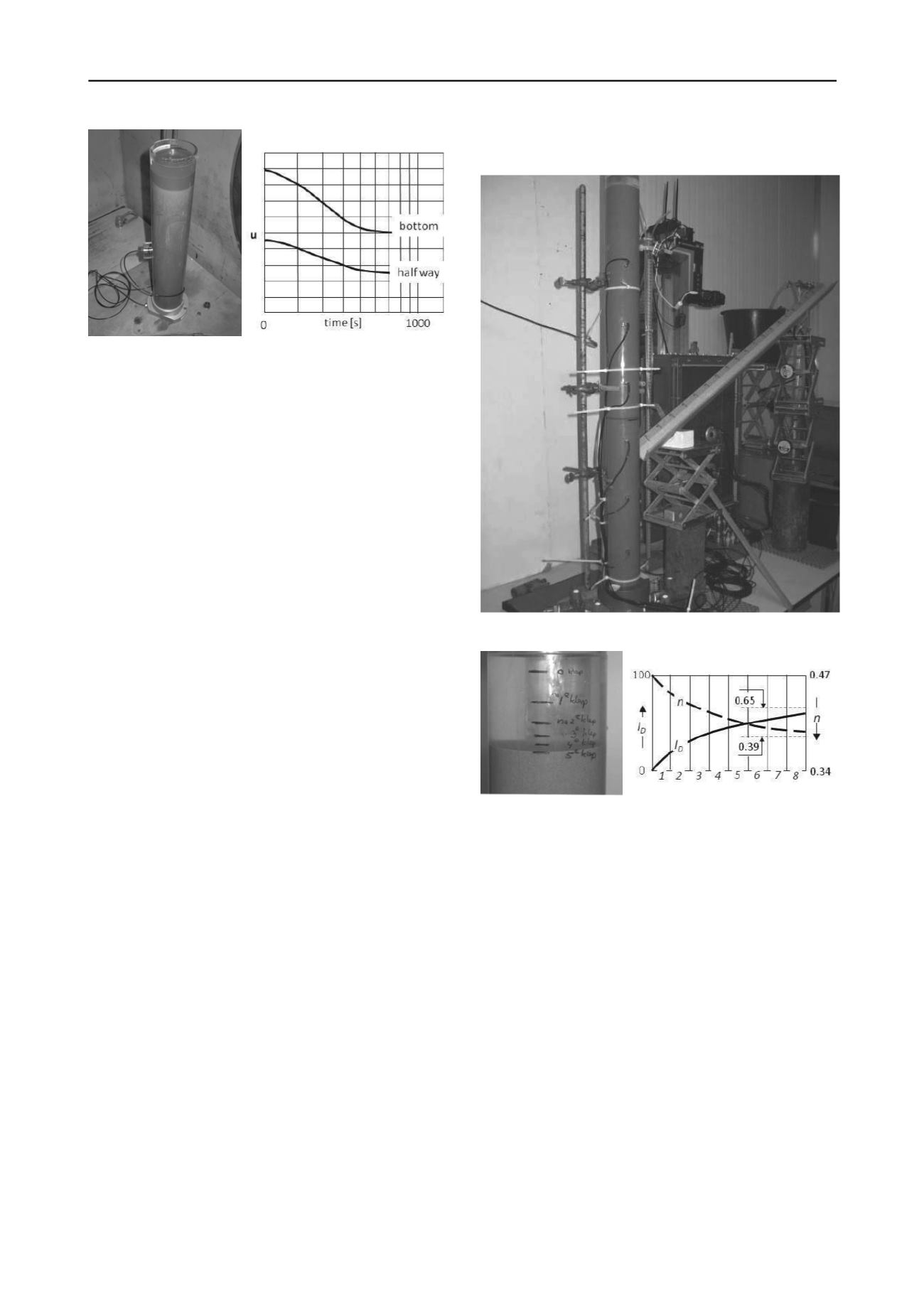

2.2

1D liquefaction effect of packing and trigger

As shown in Section 2.1, during liquefaction large excess

pore pressures can exist. It is of interest how these excess

pressures proceed in an adjacent densely packed sand

formation. In a 1D column test of 100 cm height and 6.5 cm

diameter, equipped with six sensors at 12.5 cm sequential

distance, recording total pore pressures at a sampling rate of

200 Hz, a two layer sand system was prepared with fully

saturated Baskarp B15 sand (

n

min

= 0.34,

n

max

= 0.47,

s

= 26

kN/m

3

). The bottom layer of 42 cm high was placed at a high

uniform density at

n

0.34, and the top layer of 50 cm high was

produced at a very low uniform density at

n

0.47, see Figure

4. The separation between the loose and dense formation was

marked by a thin disc of colored sand, see Figure 2. Care was

taken to eliminate any air intrusion.

Several test series have been performed. The trigger for

liquefying the top layer was produced by rolling a bullet of

0.066 kg over a inclined (20

o

) gutter impacting the column at

about 30 cm height (Figure 2) The intensity of the trigger was

changed by the rolling height (from a distance of 5 up to 100 cm

over the sloping gutter). After every impact the top level

lowering of the loose sand has been measured (Figure 3a). The

lower dense sand layer showed practically no densification

change, and in the very beginning of every hit some dilatancy

(negative excess pore pressures). The intensity of the trigger

showed full liquefaction of the loose top layer for a bullet

impact after rolling over more than 50 cm over the gutter, for

lesser the trigger intensity was too small to invoke complete

liquefaction, but excess pore pressures were observed. Next,

repeated hits of sufficient intensity showed full liquefaction of

the top sand layer each time, followed by sedimentation and

consolidation, at a decreasing tendency. The corresponding

porosity

n

and the relative density

I

D

was determined after each

hit (Figure 3b). Many impacts should reach a critical density of

n

crit

0.39 or relative density

I

D

65% (Lindenberg & Koning

1981, Poulos 1971).

Figure 2. The test setup

Figure 3a. Top level lowering Figure 3b. Effect at successive hits

The top three sensors (nr 1, 2 and 3), located in the loose

sand, showed constant high pore pressure during liquefaction,

see Figure 4. The effect of hindered dispersion during

sedimentation is noticed by a regular decrease of the pore

pressures. Similar related high pore pressures are noticed also

in lower sensors, nr 4, 5 and 6, all in the dense sand, also

decreasing in accordance with the sedimentation process of the

liquefied layer on top. After completion of the sedimentation a

hydrostatic situation is restored.

For several hits, sand settlement due to sedimentation is

shown in Figure 3a. As it seems, subsequent hits produced a

sedimentation period that seems each time about 25% shorter

than the previous one. The mud weight was about 18 kN/m

3

.

The sedimentation coefficient (defined in Section 2.1) for the

case shown in Figure 4 is:

s

v

1.5 10

-3

m

2

/s. The slight decline

of the constant pore pressure during liquefaction phase observed

in the top sensors is due to mud passing the sensor during

sedimentation. The tests reveal that during partly liquefaction

corresponding excess pore pressures extend outside the

liquefied zone, and remain high during the sedimentation, In

these tests about two minutes. Thicker layers may show

significantly longer sedimentation time.