1275

Effects of ballast thickness and tie-tamper repair on settlement characteristics of

railway ballasted tracks

Les effets de l'épaisseur de ballast et de la réparation de lien-bourreur sur le tassement des voies

chemin de fer

Hayano K., Ishii K.

Yokohama National University

Muramoto K.

Railway Technical Research Institute

ABSTRACT: The effects of ballast thickness and tie-tamper repair on the settlement characteristics of ballasted tracks are

investigated by conducting a series of cyclic loading tests on model grounds. A model sleeper at a one-fifth scale was used, and tie-

tamper implementation was physically simulated in the model tests in which relationships between the number of loading cycles and

sleeper settlement were obtained. In addition, maximum shear strain distributions generated in the model grounds were analyzed with

particle image velocimetry. Results suggest that the 250 mm ballast thickness currently adopted as the standard design is ineffective

for minimizing settlement that occurs when the nonlinearity of roadbed compressibility is relatively moderate. Moreover,

characteristics of the initial settlement process are altered significantly after tie-tamper implementation, although the degree of gradual

subsidence undergoes minimal change regardless of ballast thickness and roadbed type.

RÉSUMÉ : Les effets de l'épaisseur de ballast et de la réparation de lien-bourreur sur les caractéristiques de nivellement des voies

lestées sont étudiés. Une série d'essais cycliques de chargement sur un modèle à une échelle d'un cinquième a été effectuée.

L’exécution de lien-bourreur a été physiquement simulée dans les essais sur maquette. Les relations entre le nombre de cycles de

chargement et le déplacement sont respectées. De plus, les distributions des contraintes de cisaillement maximales du modèle sont

analysées par analyse d’image. Les résultats montrent que l’épaisseur de ballast de 250 mm adoptée actuellement comme standard est

inefficace pour minimiser le tassement qui se produit pour une compressibilité de terre-plein non linéaire relativement modérée. De

plus, le processus de tassement initial change considérablement après mise en oeuvre du lien-bourreur, malgré les effets minimes

durant l’implantation.

KEYWORDS: Railway ballasted track, Maintenance, Residual settlement, Model test

1 INTRODUCTION

Railway ballasted tracks, which are composed of crushed

stones, rails, and sleepers, usually undergo residual settlement

due to railway traffic. In order to perform appropriate

maintenance on these tracks, it is important to clarify such

settlement characteristics. However, optimum relationships

between ballast thickness and roadbed rigidity have not been

well understood

1)

, particularly with the 250 mm thick ballast

currently used as the standard design. Ballasted tracks that show

a substantial amount of settlement is often restored to the

original positions by tie-tamper implementation. However, the

manner in which this type of implementation alters the

settlement characteristics of the ballasted tracks is poorly

understood.

In this study, therefore, the effects of ballast thickness and

tie-tamper repair on the settlement characteristics of ballasted

tracks are investigated. A series of cyclic loading tests are

conducted on a model sleeper at a one-fifth scale, as shown in

Fig. 1. In the loading tests, tie-tamper repair was physically

simulated by inserting a small tool into the ballasts. In addition,

particle image velocimetry (PIV) analysis was performed to

interpret deformation of the ballasts and roadbeds.

2 MODEL GROUNDS AND CYCLIC LOADING

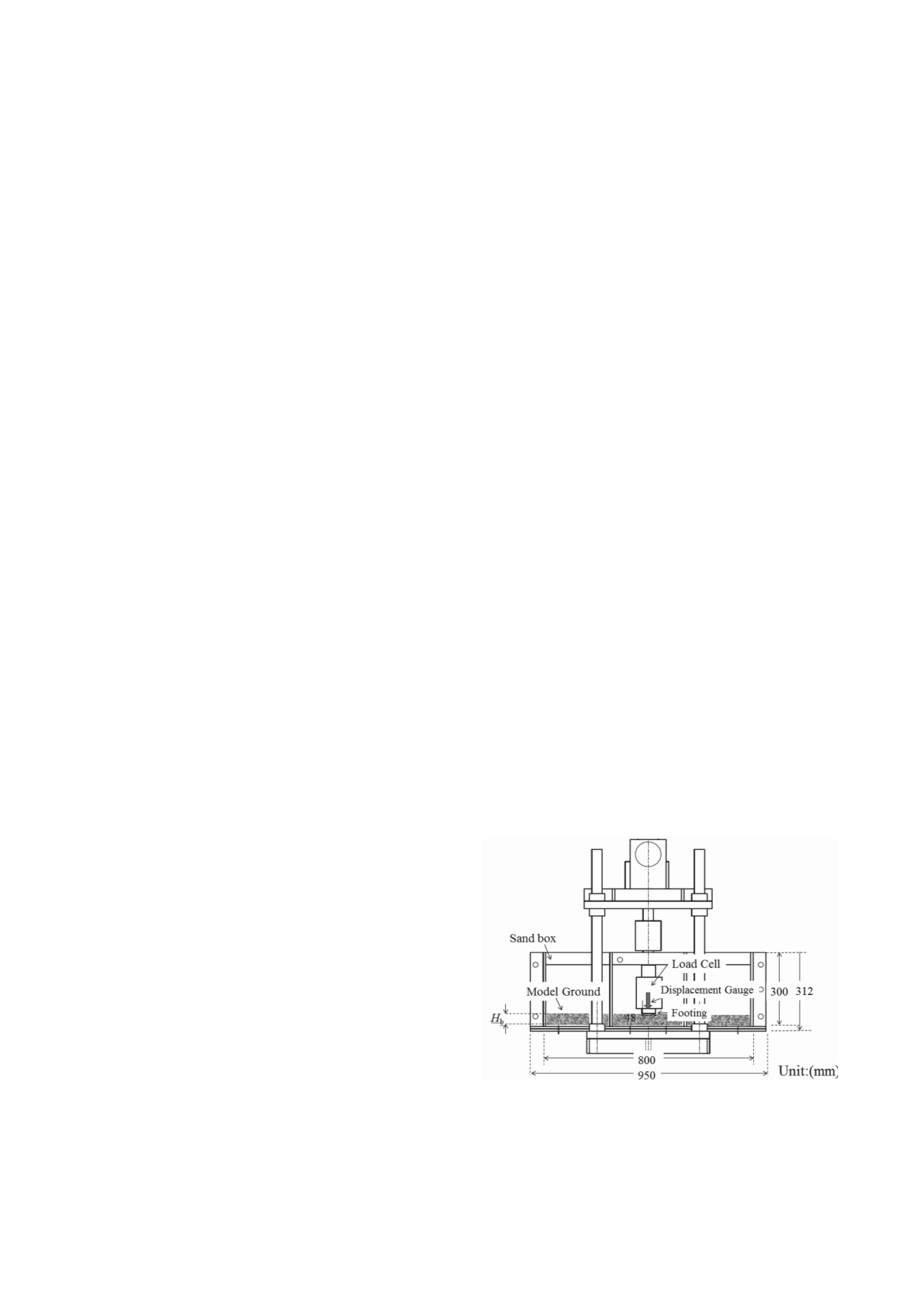

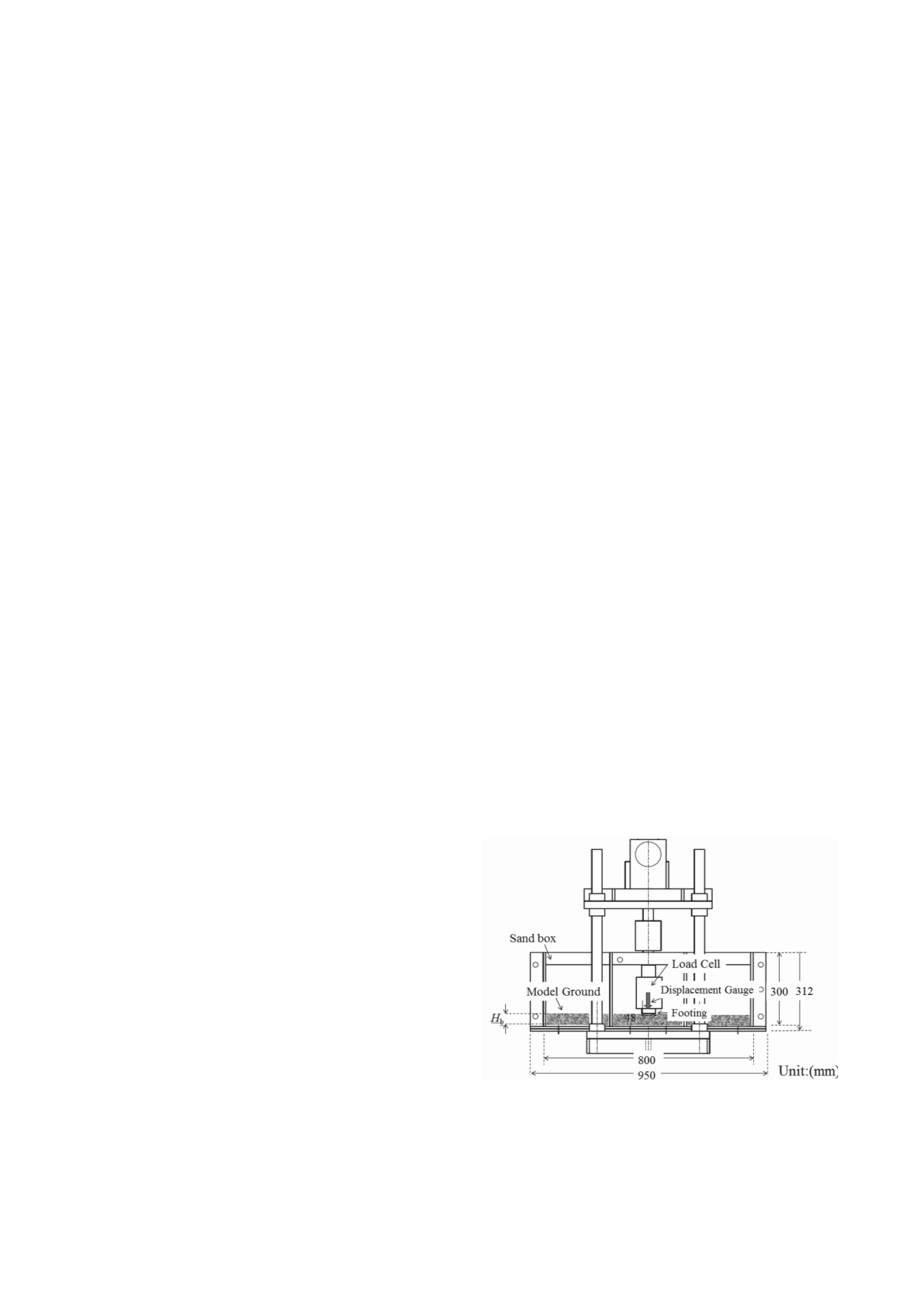

Figure 1 shows the model test apparatus used in this research.

Model grounds at a scale of one-fifth were constructed in a sand

box with interior dimensions of 800 mm wide, 304 mm deep,

and 300 mm high. A duralumin footing with a width of 48 mm

was used to model the sleeper. Crushed stones approximately

one-fifth the size of actual ballasts were selected to model the

ballasts. The maximum particle diameter

D

max

was 19 mm, and

the mean diameter

D

50

was 8.0 mm.

Cyclic loading tests were conducted on 12 model grounds

under various conditions. Crushed stones with 20, 50, and 80

mm thicknesses were constructed on four types of roadbeds

(Table 1). Crushed stones were compacted to achieve a dry

density of 1.60 g/cm

3

in each test.

Figure 1. Model test apparatus for cyclic loading test in the case of a

steel roadbed

As shown in Table 1, the roadbed in Case 1 was represented

by the bottom steel plate of the sand box. The roadbed in Case 2

was constructed with Toyoura sand (

D

r

= 90%) with a thickness