1265

Technical Committee 202 /

Comité technique 202

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

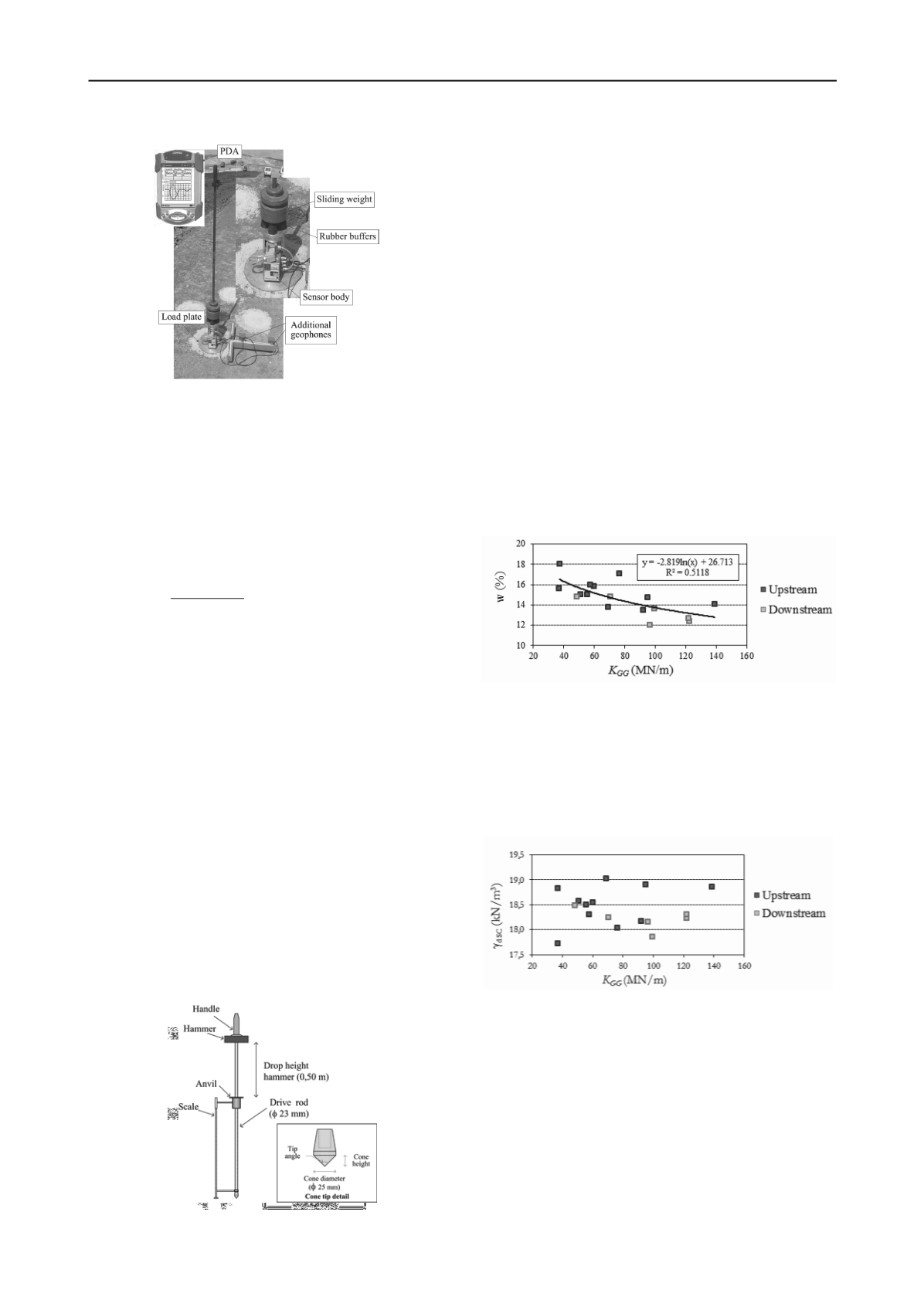

Figure 6. Prima 100 P-FWD device.

The device measures both force and deflection. The software

enables the selection of test setup and to visualize and save the

test results. Time histories and peak values of load and

deflection are displayed in a hand-held computer (PDA). The

peak values of load and deflection allow determining the elastic

stiffness modulus,

E

P-FWD

. The equation used to determine

E

P-FWD

is based on the Boussinesq’s equation. It corresponds to

calculating the surface modulus of a layered material under a

uniform circular load of radius R, assuming an uniform

Poisson’s ratio:

c

FWD P

R

f

E

2

1

(2)

where

f

is the stress distribution factor, assumed 2.0 (flexible

plate),

ν

is th

e Poisson’s ratio, assumed 0.35

,

is the (peak)

impact stress under the loading plate (kPa),

R

is the P-FWD

loading plate radius (150 mm) and

δ

c

is the (1

st

peak) P-FWD

deflection (

m).

Initially, a 300 mm diameter loading plate, four buffers, a 15

kg falling mass and a 0.8 m drop height were adopted. This

configuration proved to be inadequate due to the excessive

energy involved which caused the apparatus to detach from the

ground after impact. It was observed that this affected the

accuracy of the deflection measurement. The experimental setup

was then changed to a 10 kg falling mass and a 0.4 m drop

height, which proved to be adequate in terms of contact and

reading accuracy (Conde

et al

., 2009). With this setup the

equipment applies a contact pressure between 85 and 100 kPa.

2.6

DCP testing

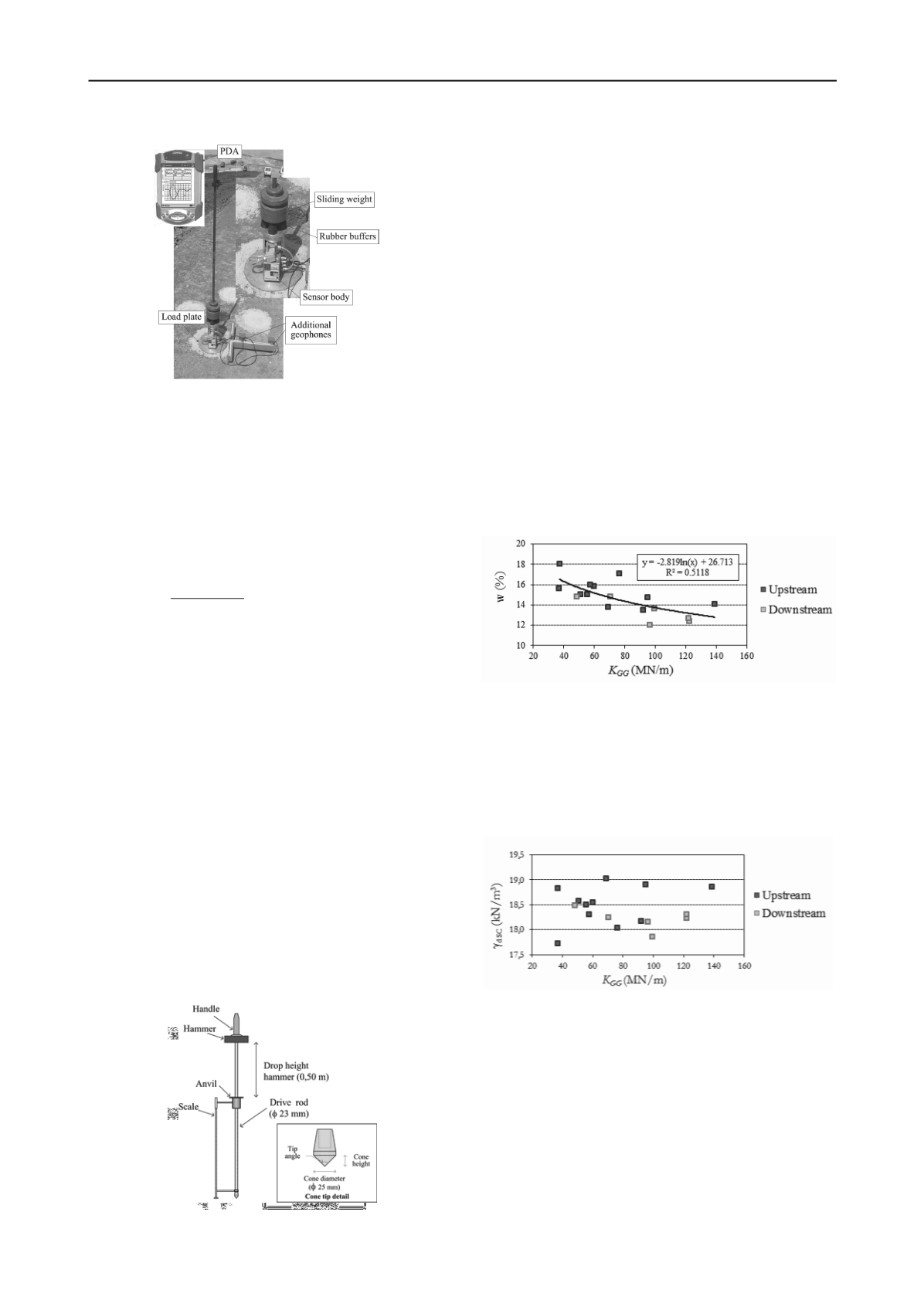

Dynamic cone penetrometer (DCP) allows a simple, fast, and

economical usage and provides continuous measurement of the

penetration resistance of embankment or pavement layers. The

DCP consists of a steel rod with a cone tip at the end. In this

study a light weight configuration was used, i.e. with a 10 kg

hammer, with a falling height of 50 cm (Figure 7).

Figure 7. DCP device.

In this study DCP testing was performed according to

EN ISO 22476-2 standard.

The readings were taken

continuously through the compaction layer depth, i.e. along 40

cm, and recorded every 10 cm. Based on the total number of

blows required to drive the penetrometer through the layer, the

average penetration rate at each 10 cm penetration PN10

(mm/blow) or the cumulative number of blows N

10

were was

calculated.

3 RESULTS ANALYSIS

To evaluate the performance of these devices as tools for the

compaction control of embankment layer, the sensitivity of the

results to variations in water content and in dry density of

geomaterials determined by traditional methods was assessed.

3.1

K

GG

results

Figure 8 shows the correlation between water content (w) and

K

GG

. The chart shows some scattering about the adjusted

negative exponential trend which limits the quality of the

adjustement. A significant increase of the geogauge stiffness

with decreasing water content may be inferred from the data

both in the upstream and in the downstream shells.

Figure 8. Relation between soil stiffness, k

GG

, and water content, w.

Regarding the dependence of

K

GG

on the

in situ

dry density,

the results in Table 2 present minor variations of the relative

compaction, i.e. of

d SC

,

thus making the correlation analysis

dificult. Conde

et al

. (2010) analyzed these results concluding

that small and erratic sensitivity of stiffness values determined

by geogauge occurred with only relatively small variations in

dry density (Figure 9).

Figure 9. Soil stiffness,

k

GG

, and dry density,

d SC

, results.

The joint consideration of both results seems to indicate that

soil stiffness is only a reliable predictor of the water content

variation. This sensitivity of stiffness to changes in water

content were also observed by Abu-Farsakh

et al.

(2004) in a

study conducted on fine soils (silt, sandy clay and clay).

3.2

E

P-FWD

results

Figure 10 shows the relationship between the elastic stiffness

modulus (

E

P-FWD

) and the

in situ

water content (w). While the

adjusted trend is again of the negative exponential type, a

smaller scatter is now observed in comparison with that of the

geogauge results.

100 P-FWD device.

measures both force and deflection. The software enables the selection of test setup and to visualize and save

s. Time histories and peak values of load and deflection are displayed in a hand-held computer (PDA). The peak

and deflection allow determining the elastic stiffness modulus,

E

P-FWD

. The equation used to determine

E

P-FWD

he Boussinesq’s equation. It corresponds to calculating the surface modulus of a lay red m terial under a

lar load of radius R, assuming an uniform Poisson’s ratio:

c

R

f

2

1

(1)

stress distribution factor, assumed 2.0 (flexible plate),

ν

is the Poisson’s ratio, assumed 0.35,

is the (peak)

under the loading plate (kPa),

R

is the P-FWD loading plate radius (150 mm) and

δ

c

is the (1

st

peak) P-FWD

).

300 mm diameter loading plate, four buffers, a 15 kg falling mass and a 0.8 m drop height were adopted. This

proved to be inadequate due to the excessive energy involved which caused the apparatus to detach from the

mpact. It was observed that this affected the accuracy of the deflection measurement. The experimental setup

nged to a 10 kg falling mass and a 0.4 m drop height, which proved to be adequate in terms of contact and

acy (Conde

et al

., 2009). With this setup the equipment applies a contact pressure between 85 and 100 kPa.

sting

e penetrometer (DCP) allows a simple, fast, and economical usage and provides continuous measurement of the

sistance of embankment or pavement layers. The DCP consists of a steel rod with a cone tip at the end. In this

eight configuration was used, i.e. with a 10 kg hammer, with a falling height of 50 cm (Figure 2).

device.

dy DCP testing was performed according to EN ISO 22476-2 standard. The readings were taken continuously

mpaction layer depth, i.e. along 40 cm, and recorded every 10 cm. Based on the total number of blows required

enetrometer through the layer, the average penetration rate at each 10 cm penetration PN10 (mm/blow) or the

mber of blows N

10

were was calculated.