1257

Technical Committee 202 /

Comité technique 202

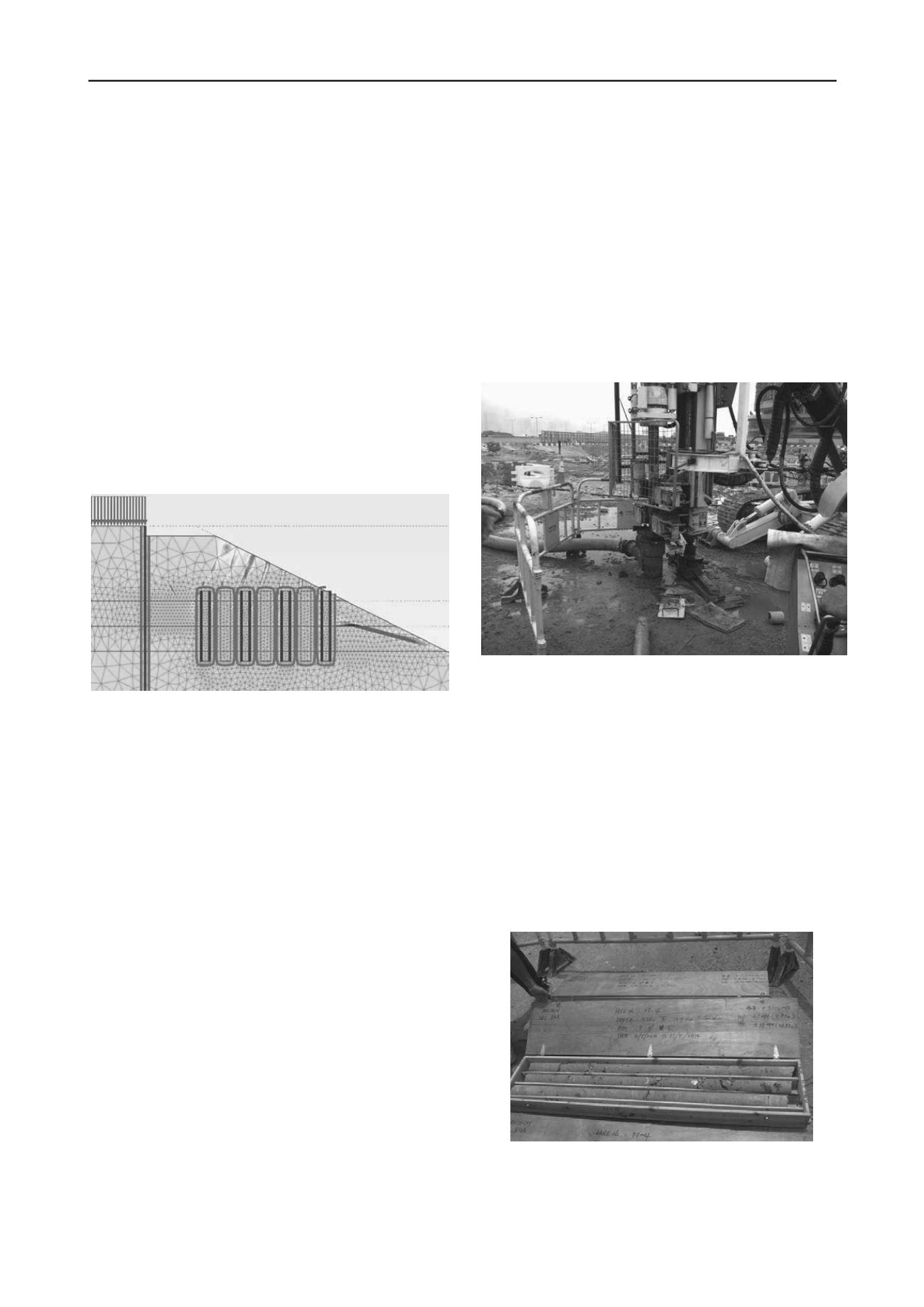

simplified design scenario shown in Figure 2 if ground

treatment is not carried out. In the absence of ground treatment,

equilibrium solutions could not be obtained and the likely

failure mechanisms are shown in Figure 3. The predicted failure

mechanism involves concentrated shear strains mobilised along

the base of the marine clay layer due to the constant strength

assumption. The overall stability is directly dictated by the

elevation of the soft marine clay layer which controls the

overburden pressure exerted on the potential failure soil mass.

To enhance the overall stability, jet grouting works was

proposed. The potential working principle of the jet grout

columns has been studied by finite element analyses. The

technique of strength reduction has been used in the analysis to

quantify the margin of safety and to identify the most critical

failure mechanism of the design scheme. In the analyses,

several rows of 2 m diameter discrete jet grout columns which

pass through the marine clay and alluvium layers are assumed.

The uniaxial compressive strength (UCS) and the Young’s

modulus of the jet grouted material are assumed to be 2 MPa

and 300 MPa respectively. Due adjustment of these parameters

have been made in the plane strain models.

Figure 4. Finite element prediction for bermed excavation with jet

grouting - incremental shear strain distributions at failure.

Figure 4 shows the incremental shear strain distributions at

failure when soil strengths have been reduced by a factor of

1.45 through strength reduction calculations. It can be seen that

the most critical failure mechanism no longer involves a sliding

plan along the base of the marine clay layer due to the presence

of the jet grout columns. Instead, a local failure in the marine

clay and alluvium is observed.

In the analysis, the jet grout columns are modeled as a non-

porous elastic perfectly plastic material, with the maximum

shear strength governed by the Mohr-Coulomb failure criterion.

Jet grouted material is brittle and therefore the mobilised shear

strains in the jet grout columns have been calculated to ensure

sufficient strength can be mobilised at small deformation. A

limiting criterion of maximum shear strain of 0.5% has been

adopted.

The design scenario depicted in Figure 2 is a gross

simplification of the actual site conditions. It conservatively

considers the adverse effects of the presence of soft marine clay

on the overall stability. The actual characteristics of the marine

clay, including its strength, thickness and elevation, may vary

across the site. The finite element analyses merely confirm the

feasibility of the design scheme under an extreme condition.

The actual amount of jet grout columns to be installed is

determined by considering the local ground conditions,

excavation profiles and the characteristics of the marine clay.

The key design criteria are the overall safety margin of the

excavation including the slope in front of the wall, the

mobilised deformation in the jet grouted material as well as the

structural forces induced in the diaphragm wall. Verification of

the assumed material parameters for the jet grout columns is

described in the next section.

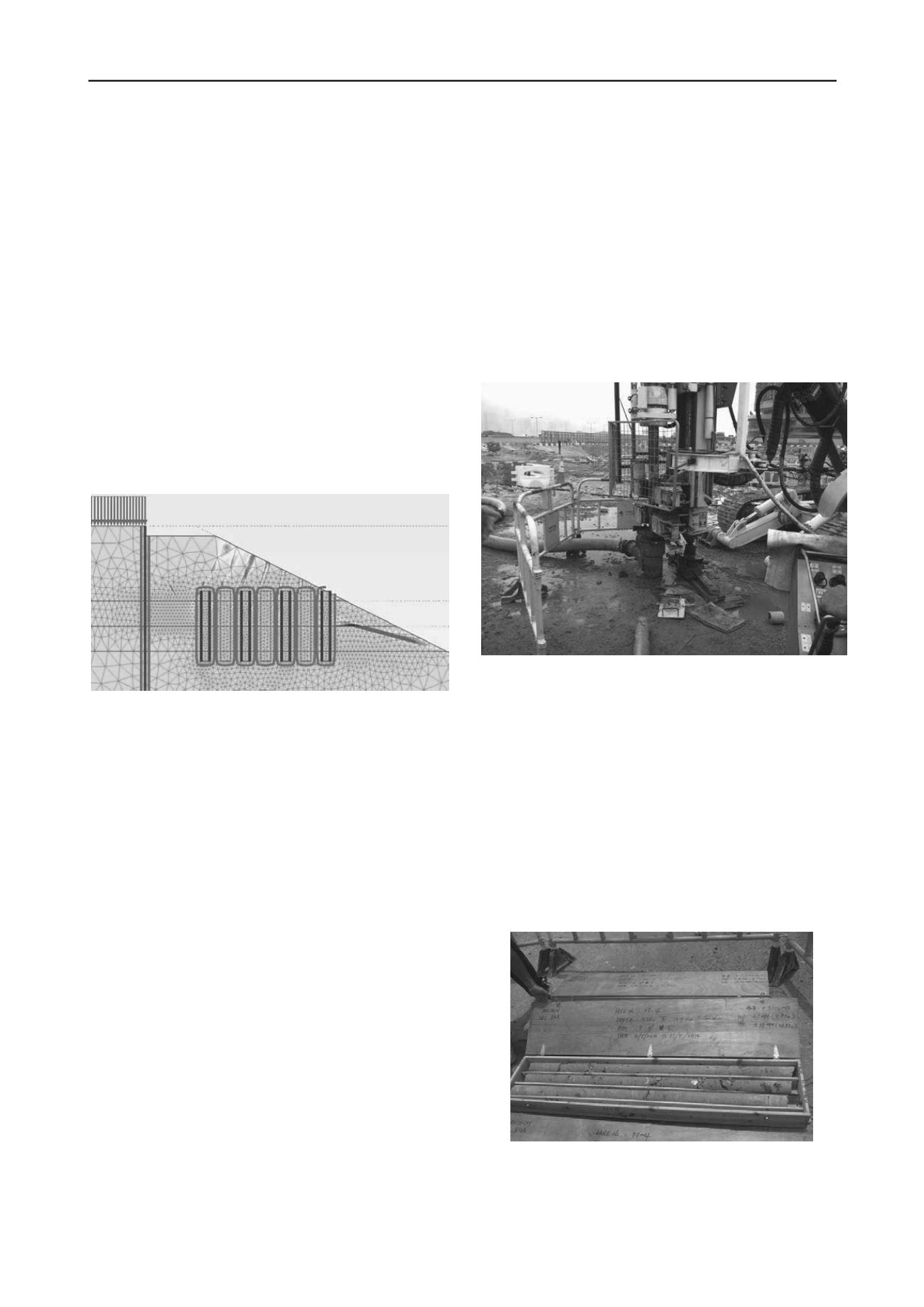

3 PERFORMANCE VERIFICATION

Although jet grouting has been used widely in many parts of the

world, it has not been common in Hong Kong. Therefore, not

much field data was available. As such, a site trial was carried

out before commencement of the actual jet grouting works. The

purpose of the site trial is to determine the control parameters of

the grouting operation, for example, the grout pressure, nozzle

size and lifting rate, etc. In addition, the site trial serves to

confirm that the assumed design strength and stiffness of the jet

grouted materials can be obtained. A total of twelve trial jet

grout columns were constructed using different combinations of

operation parameters. A photo showing the jet grouting works is

shown in Figure 5. The entire process is fully automated with

all the operation parameters shown on a digital display panel.

Figure 5. Plant used for jet grouting works with fully automated control

system.

A comprehensive post-grouting investigation was carried

out. This included multiple full-depth coring in the trial jet grout

columns, laboratory testing of the core samples and in-situ

pressuremeter tests in the core holes. Core samples were

obtained at differnet depths and at different locations in order to

confirm that an effective diameter of 2 m could be acheived.

The core samples were tested to obtain the Young’s modulus

and the UCS of the specimens. In-situ pressuremeter tests were

conducted in the core holes to measure the stiffness of the

grouted zone. The final operation parameters of the jet grouting

works were determined according to the results of site trial.

For working jet grout columns, full-depth corings were

obtained at a particular sampling frequncy as a quality control

measure. Typical cores are shown in Figure 6.

Figure 6. Typical core sample obtained from jet grout column