1256

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

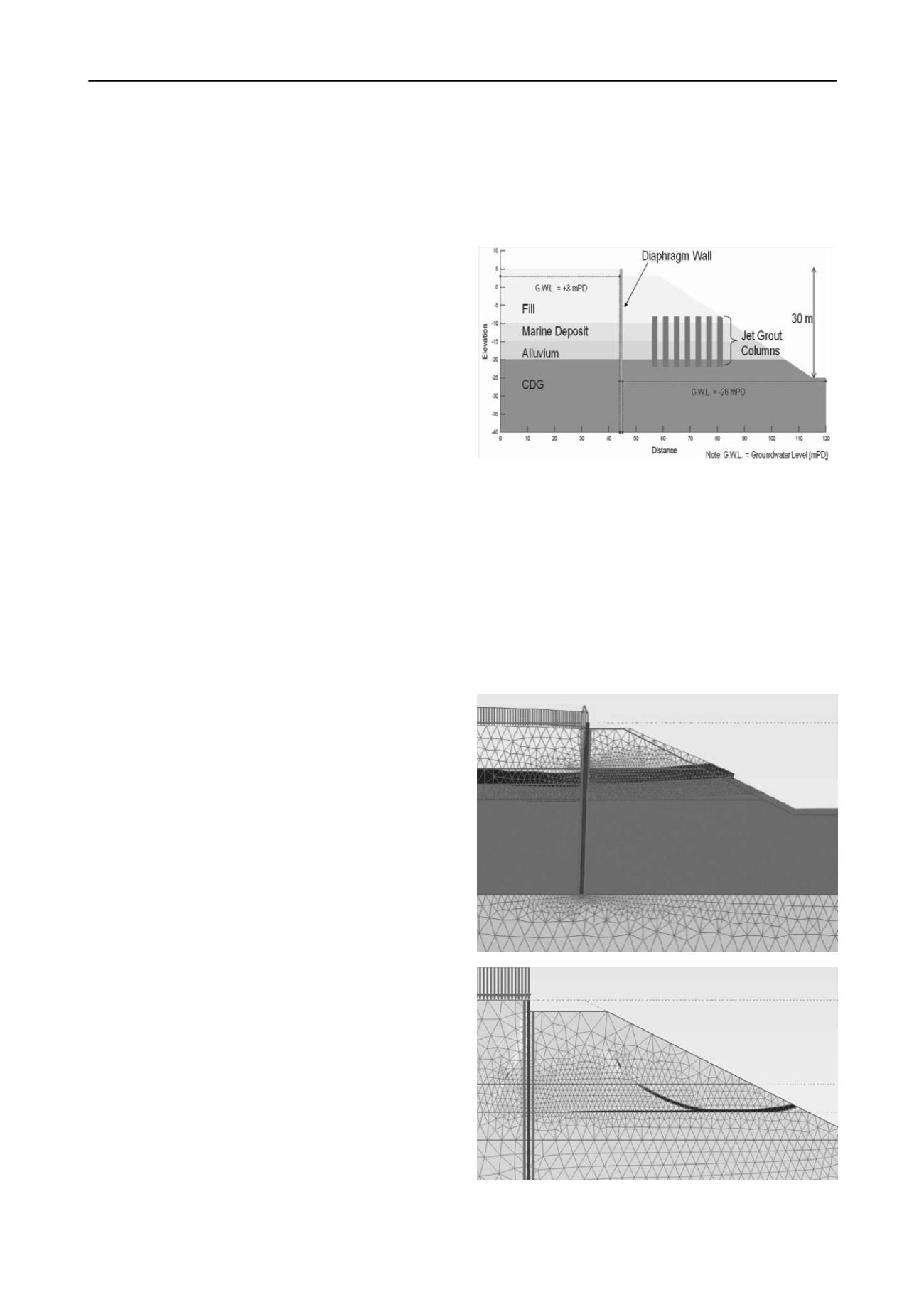

2 DESIGN OF THE DEEP EXCAVATION

The 30 m deep excavation at WKT has a plan area of

approximately 550 m by 220 m, and is surrounded by high-rise

residental and commerical buildings in West Kowloon – an

urban area of Hong Kong. Construction of large diameter bored

piles and rock-socketted steel H-piles for supporitng the station

structure and the perimeter diaphragm wall was carried out

before excavation commenced. The diaphragm wall serves as

the temporary retaining structure for the deep excavation, the

permenent wall of the station structure, as well as a load bearing

wall to support the vertical load from the superstructure. This

Section describes the ground conditions of the site, the

construction seqenence and the design considerations of the

deep excavation.

2.1 Ground conditions

The solid geology within the site area comprises Kowloon

Granite from the Cretaceous Period of the Mesozoic Era which

is a monzogranite pluton centered on Kowloon and Hong Kong

Island. The superficial deposits include fill and transported

materials such as alluvium, colluvium, marine deposits,

estuarine deposits and the like.

Reclamation fill has been placed on the site following the

West Kowloon reclamation works carried out in the 1990s. The

fill comprises the reclamation deposits and the remnants of the

old seawalls, old breakwaters, revetments, old ferry pier and

existing layers of building debris and rock fill. The in-situ

deposits include weathered rock and the soil derived from the

weathered rock such as saprolite and residual soil (i.e. the Grade

VI material according to GEO (1988)). Variably jointed rock

and soil masses with different proportions of rock and soil are

present within the in-situ deposits.

The site topography prior to the bulk excavation is generally

characterised as flat and the average ground level is at about

+5.5 mPD. The available groundwater level records from

standpipes and vibrating wire piezometer indicate that the

highest recorded groundwater level ranged from +1.56 mPD to

+3.60 mPD and the lowest groundwater level recorded ranged

from -1.29 mPD to +1.94 mPD.

2.2 Construction sequence

Excavation and construction of the station structure is carried

out by two separate contractors who adopt different construction

methods. The contractor on the northern side adopts open cut

excavation (see Figure 1) which is then followed by bottom-up

construction. On the southern side, the contractor adopts top-

down construction for the top two levels of slabs and then

changes to bottom-up construction for lower levels.

The focus of this paper is the open cut excavation carried out

near the northern part of the site. Upon completion of the

foundation works and diaphragm wall construction, jet grouting

was carried out at locations where soft marine clayey deposits

are present which adversely affect the stability of the bermed

excavation. After sufficient strength had been gained in the jet

grouted material, temporary cut slopes at a gradient of 1 on 2

were formed in front of the diaphragm wall. This was followed

by bottom-up construction of the central core of the station

structure. Construction of the entire structure would then be

completed by top-down method between the diaphragm wall

and the core station structure where the temporary slopes are

gradually removed and replaced by reinforced concrete slabs

connecting the diaphragm wall to the core station structure.

2.3 Design considerations

Figure 2 shows a simplified design scenario which illustrates

the design concept. The diaphragm wall and the soil berm are to

support an excavation with a maximum depth of approximately

30 m. Since the diaphragm wall is designed as a foundation

element for vertical loading, the wall is founded on the bedrock

with a nominal embedment of 300 mm. The sufficiency of the

embedment depth of the wall has been checked by trial wedge

methods. For areas with a shallow rockhead, mini piles, denoted

as shear pins, were constructed beneath the base of the

diaphragm wall to increase the resistance against overturning.

Figure 2. Simplified design scenario of bermed excavation design with

ground treatment by jet grouting.

The trial wedge method considers the soil berm as a passive

support as far as stability of the embedded wall is concerned.

The stability of the soil berm has to be considered separately.

The marine deposits sandwiched between the reclamation fill

and alluvium consist of interbeded cohesive and granular

materials. The cohesive portion typically comprises of clay and

in places silt with various proportion of sands and gravels. The

undrained shear strength ranged from a few kilopascals to >200

kPa. A general design value of 30 kPa was adopted, except for

marine clay at shallow depths where a lower value of 20 kPa

was used.

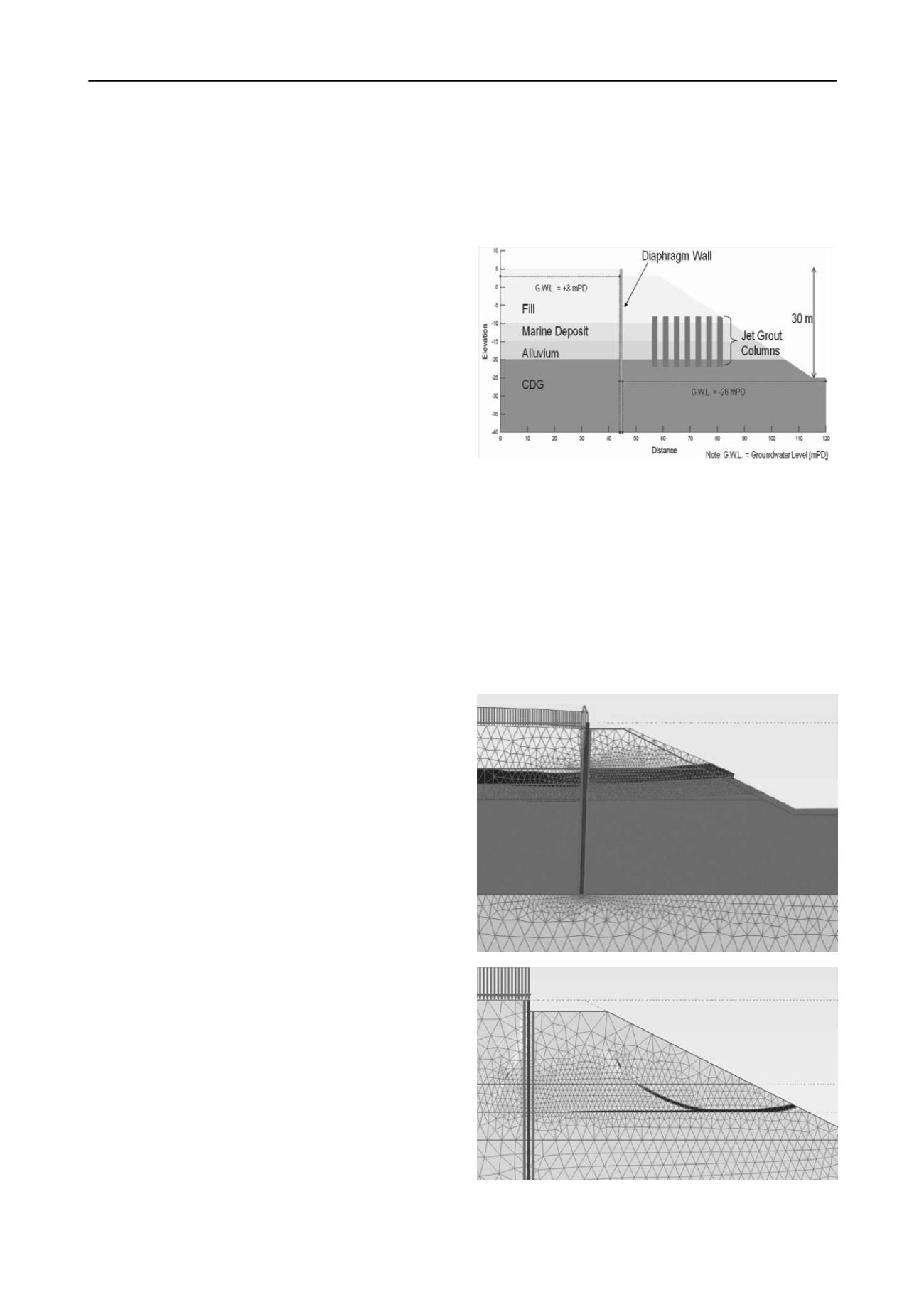

(a)

(b)

Figure 3. Predictions of failure mode from finite element analysis (a)

total deformation, (b) incremental shear strain distributions

Finite element analyses have been conducted using Plaxis to

predict the behaviour of the bermed excavation for the