1251

Technical Committee 202 /

Comité technique 202

stress state after load repetitions, overconsolidation ratio OCR

of natural soft soil is systematically recalculated due to the

modification of the stress history. In total 10 iterations of cyclic

loading have been adopted with 10 load repetition each one, so

that the analysis reaches 100 load applications.

The decrease of clay stiffness due to increase of the load

repetitions is well known issue. To take into account this effect

Idriss et al. (1978) proposed that the decrease in modulus could

be accounted for by a degradation index

according to (1).

= (E

S

)

N

/ (E

S

)

1

= N

-t

(1)

Where: (E

S

)

N

is the secant young’s modulus for Nth cycle;

(E

S

)

1

is the secant young’s modulus for the first cycle; and t is a

degradation parameter, which represent the slope of the curve

log E

S

– logN.

On the other hand, in order to take into account the influence

of the typical small strains produced below the pavement

structures, it was assumed the soil stiffness degradation due to

strain level. Hardin and Drnevich (1972) proposed a simple

hyperbolic law to describe how the shear modulus of soil decays

with the increase of shear strains. Afterward, Santos and Gomes

Correia (2001) modified this relationship to determine de

variation of secant shear modulus G

S

as a function of the initial

(and maximum) shear modulus at small strains G

0

, and of the

shear strain

0.7

related to the 70% of the maximum shear

modulus 0.7G

0

as a threshold. Equation 2 describes this relation

in the domain of a certain range of shear strain, commonly

within values from 1·10

-6

to 1·10

-2

. The tangent shear modulus

G

t

can be determined taking the derivative of G

S

.

7.0

0

S

0.385

1

G

G

;

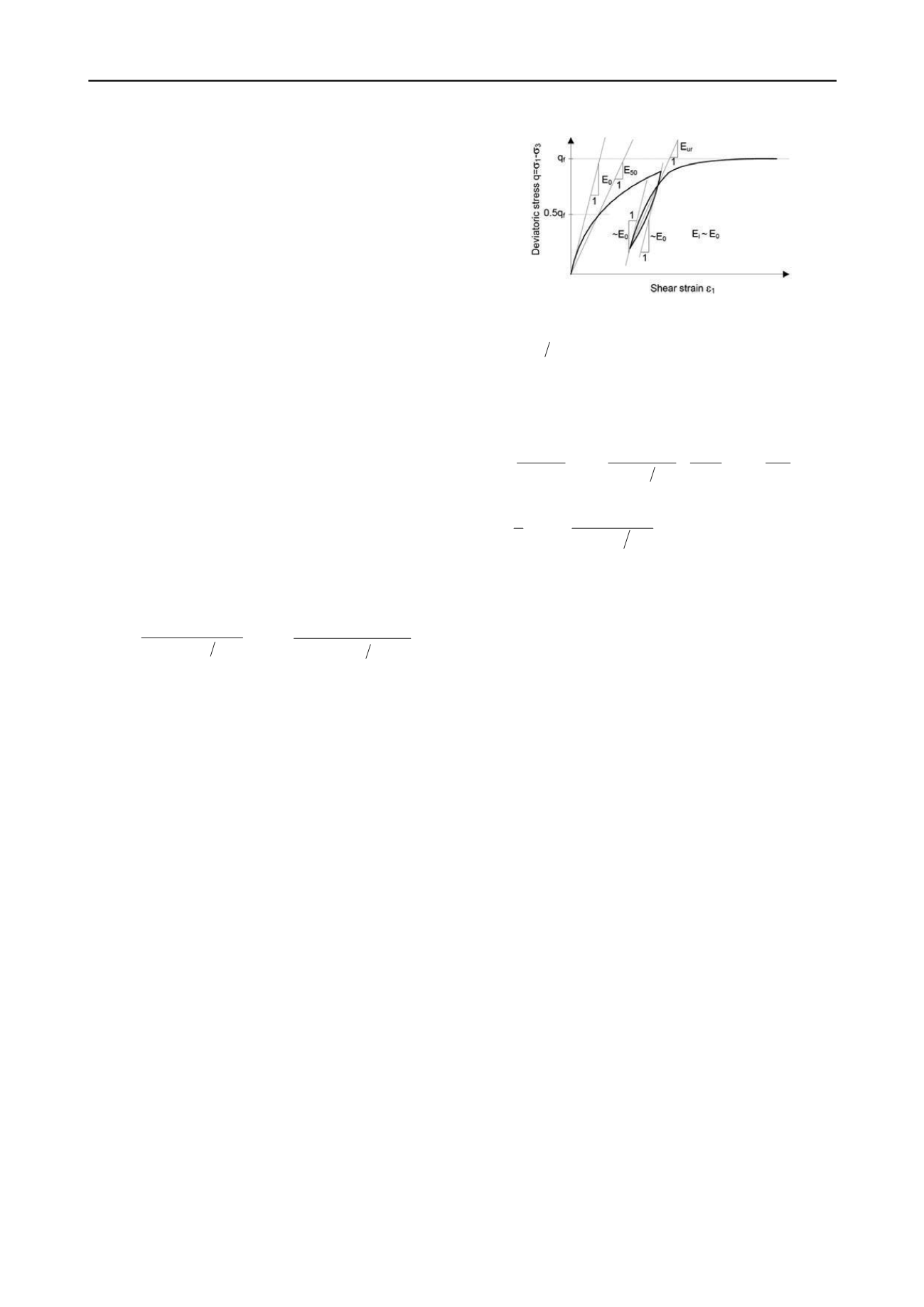

Figure 3. Hyperbolic stress-strain relation and moduli E

0

, E

50

and E

ur

adopted in the HS-small model.

S

D

Eπ4 Eξ

(3)

Where E

D

is the dissipated energy in a load cycle comprised

from the minimum to maximum shear strain (Equation 4), while

E

S

is the energy stored at maximum shear strain

c

(Equation 5).

0.7

c

0.7

c

0.7

c

c

0 0.7

D

γ

aγ

1 ln

a

2γ

aγ γ1

γ

2γ

a

G 4γ

E

(4)

7.0

2

2

0

2

S

22

2

1 E

c

c

cS

a

G

G

(5)

Where a= 0.385

2

7.0

0

t

0.385

1

G

G

(2)

This approach is based on the research carried out by

Vucetic and Dobry (1991) and Ishihara (1996), which

demonstrated that beyond a volumetric threshold strain

v

the

soil starts to change irreversibly. At this strain level, in drained

conditions permanent volume change will take place, whereas

in undrained conditions pore water pressure will build up

(Santos and Gomes Correia 2001). Furthermore, it is well

known that the degradation of G/G

0

with shear strains depends

on many factors e.g. plasticity index, stress history, effective

confine pressure, frequency and number of load cycle, etc.

Indeed, with the purpose of consider the influence of the most

importance factors on the degradation of shear moduli, Santos

and Gomes Correia (2001) used the average value of

v

related

to the stiffness degradation curves (G/G

0

= f(

)) presented by

Vucetic and Dobry (1991), in order to define a unique curve of

G/G

0

as a function of normalized strain

/

v

. In this way they

concluded that when the ratio

/

v

= 1 the best fit tends to

correspond to a ratio G/G

0

= 0.7.

This approach aids to develop the small-strain stiffness

model (HSsmall) proposed by Benz (2006) that is already

included in the latest version of Plaxis code. Unlike the standard

Hardening Soil Model (Schanz et al. 1999) where a linear stress

strain relationship controlled by the stiffness E

ur

is assumed

during unloading-reloading process, the HS-small model takes

into account hysteresis loops during loading and unloading

cycles with moduli variation among initial E

0

, secant E

50

and

unloading-reloading E

ur

stiffness (Figure 3). In fact, such model

also presents a typical hysteretic damping when the soil is under

cyclic loading due to energy dissipation caused by the strains;

Brinkgreve et al (2007) proposed an analytical formulation to

estimate the local hysteretic damping ratio according to

Equation 3:

Once assumed the calculation procedure described above,

the hysteretic damping ratio according to Equation 3 is

estimated from the strain updating after each iterative

calculation (10 iterations each consisting of ten load

repetitions), considering the calibration of soil stiffness due to

strain level (

), current stress state (OCR) and number of load

repetitions (N). Moreover, viscous damping effects may be

added by means of the rayleigh damping features of the used

Plaxis version (v8.2). Rayleigh damping consists in a

frequency-dependent damping that is directly proportional to

the mass and the stiffness matrix through the coefficients

and

respectively (C =

·

M +

·

K). In fact, the damping process

subjected to a cyclic loading should be analyzed from the

combination of two approaches: mechanical hysteretic damping

depending on the strains level, and viscous damping depending

on the time, which has to fit well with both, natural material and

load application frequency. For this purpose the values adopted

for Rayleigh coefficients are

=

= 0.01.

As small-strain stiffness model is not included in the version

8.2 of Plaxis code used here, the analytical solution of

Brinkgreve et al (2007) is adopted to verify and compare the

damping ratios between the results from the finite element

modeling and the results from such analytical solution. Finally,

the behavior of subgrade soil is analyzed regarding the

accumulated vertical strains due to the cyclic load repetitions.

3.4 Modelling results

3.4.1 Subgrade response under static loading

The settlement after construction stage rise up to 25 mm, which

should last less than few months according to the typical

projects requirements. Nevertheless, the consolidation process

may lasts between 1.5 to 2.5 years considering a soil

permeability of 10

-8

to 10

-9

m/s. Regarding the operation stage,

the maximum value of excess pore pressure due to axle load

rises up to 5.5 kPa. The response of subgrade soil when the axle

load is applied under static conditions can be appreciated

through the values of deviator stresses as well as vertical

resilient and permanent strains depending on the depth

(Figure 4a).