1264

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2.2

Experimental layout

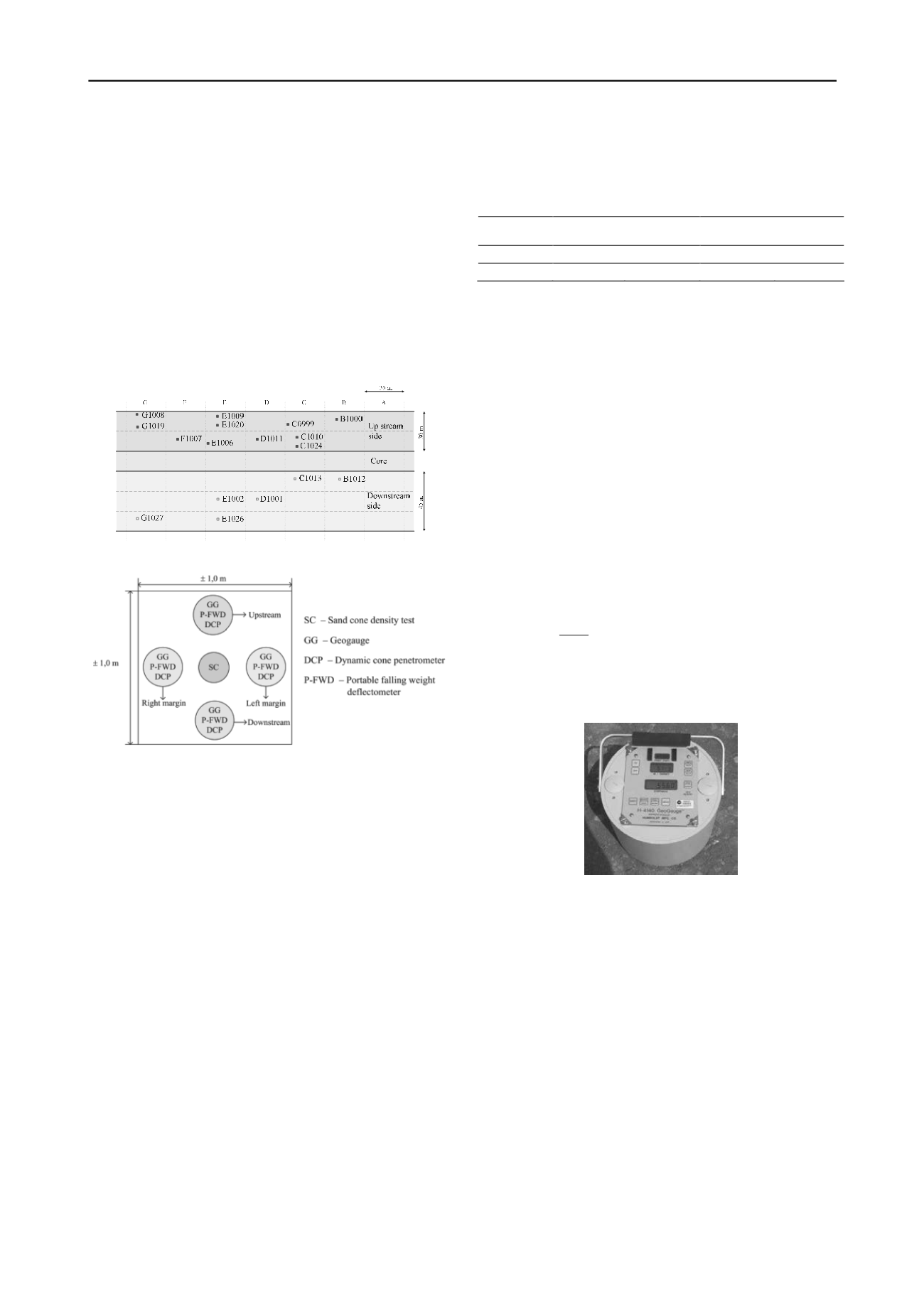

In Figure 3 the field tests performed at the different locations

within 35 m wide bands, from A to G, are summarized. The

layout of the field tests carried out at each position is illustrated

in Figure 4. A cross-shaped configuration was selected with the

traditional tests at the center and the performance base methods

at the cross ends. The sand cone density test was used to

measure in-place unit weight, according to ASTM D 1556

standard. Soil samples were also collected from each test

position for water content (w) determination in the laboratory

by the microwave oven heating procedure, following ASTM D

4643 standard. Measurements with geogauge and P-FWD were

taken at surface. The DCP readings were taken continuously

along the compaction layer depth, i.e. 40 cm, and recorded

every 10 cm.

Figure 3. Plan view of the test positions.

Figure 4. Tests arrangement at each test position.

In order to limit the disturbance caused by each type of test

on the results, the following sequence of tests was selected:

geogauge, P-FWD and DCP.

2.3

Compaction control

The required properties of the compacted fill layers were

established during the construction of a trial embankment.

Accordingly, the layers of the shells were compacted to 40 cm

thickness by eight passes of a smooth steel drum vibratory

roller, model CAT 583. A minimum relative compaction of

95% to the reference standard Proctor was required for

compaction approval. Further, regarding maximum water

content deviation to optimum water content (owc) up to + 2% at

the upstream shell and between

–

2% to + 1% at the

downstream shell was required.

The soils used in the dam construction came from borrow

areas; therefore some degree of heterogeneity in their physical

and mechanical properties was anticipated. The compaction

control in heterogeneous materials, based on dry density and

water content determination at each controlled point would

involve a volume of work and delay in the results presentation,

with potential interference with the construction schedule. Thus,

the Hilf method was selected for control of compaction work

(ASTM D 5080). It allows the determination of the relative

compaction, RC, and the water content deviation from owc,

w,

based uniquely on the soil density value, thus without water

content measurement and previous knowledge of the Proctor

reference curve. Table 2 shows the range of results of the

compaction control by the Hilf method in upstream and

downstream shells. As summarized in Table 2 the relative

compaction and water content deviation values lie within the

expected ranges.

Table 2. Range of compaction results control by the Hilf method.

Location

(kN/m

3

)

d max.

(kN/m

3

)

RC

(%)

w

(%)

Upstream 20.2 to 21.3 17.5 to 18.8 98.5 to 99.7 +0.1 to +1.7

Downstream 19.9 to 20.8 17.6 to 18.3 97.6 to 99.7 -0.7 to +0.7

2.4

Geogauge testing

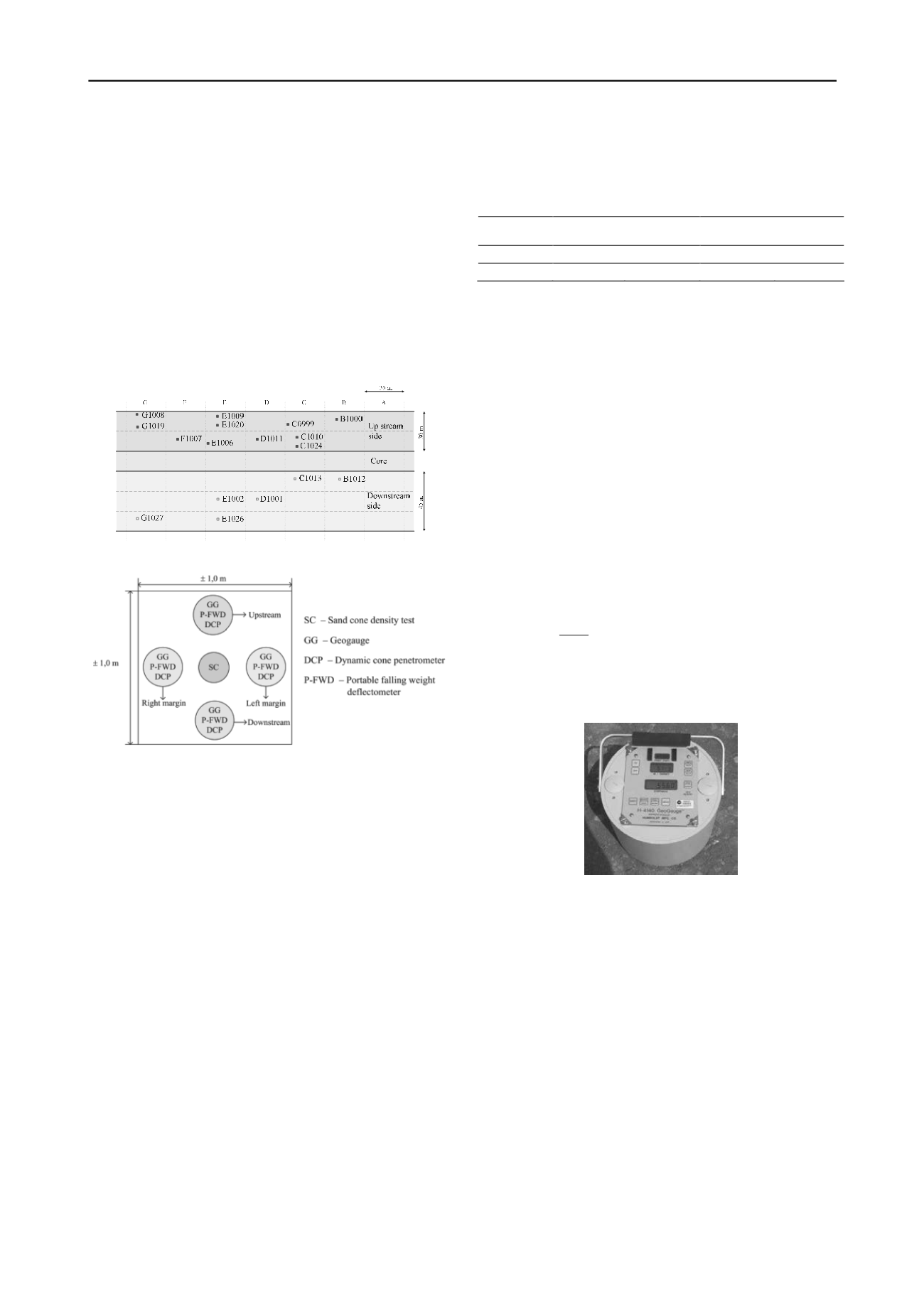

The geogauge device testing procedure is based on the response

of a linear elastic medium to a dynamic force applied at the

surface. It allows the determination of the elastic Young

modulus of the near surface material. The geogauge is a

cylinder with a height of 270 mm and a diameter of 280 mm, as

shown in Figure 5. The equipment weighs approximately

100 N. The device rests on a circular ring placed and seated

firmly at the soil surface. The base cylinder has an outside

diameter of 114 mm and an inside diameter of 89 mm. The

geogauge shaker scans the frequency domain between 100 and

196 Hz with 4 Hz increments, totalizing 25 individual

frequencies (Alshibli

et al

., 2005). During the test sequence, the

small amplitude deflection

and the applied force F are

recorded, thus enabling the determination of the soil vertical

specific stiffness, the so-called geogauge stiffness (

K

GG

). The

average of the 25 stiffness values is taken as the representative

value of

K

GG

.

The elastic Young’s modulus (

E

GG

) of the soil is

then computed by the equation:

R .

ν

-

k E

GG GG

771

1

2

(1)

where

is the

Poisson’s rat

io and

R

is the radius of the

geogauge base (57.15 mm), being

E

GG

expressed in MPa and

K

GG

in MN/m.

Figure 5. Geogauge device.

2.5

P-FWD testing

The P-FWD device used was a Prima 100. It consists of four

major parts: the sensor body, load plate, buffer system and

sliding weight (Figure 6).

The sensor body encloses a load cell and a geophone. The

latter is spring mounted at the center of the load plate and

measures the deflection of the surface caused by the impact

load. The Prima 100 allows the user to vary the drop height,

weight, plate diameter and the number of rubber buffers.

The adjustment of the weight and drop height allows one to

adjust the impact energy. Additional drop weight increases the

stress exerted by the plate. By changing the size of the loading

plate diameter the stress imparted onto the sub-grade soil may

also be adjusted. The number of rubber buffers can be selected

to alter the duration of the load impact impulse.