1284

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2.1

Test setup and procedure

A steel plate of 300 mm diameter and 50 mm thickness was

used to represent a hard base such as the deck of a bridge, or

hard rock. A thick sand layer of 100mm thickness was used to

simulate a typical ‘weak’ subgrade. The drop hammer was

raised mechanically to the required height and then released by

an electronic quick release system. After 10 blows, an

attenuation of strains in the ballast layer was reached.

2.2

Single impact loading

The impact load-time history under a single impact load is

shown in Figure 1. Two distinct types of peak forces were seen

during impact loading: (a) an instantaneous sharp peak with

very high frequency

P

1

, and (b) a gradual peak of smaller

magnitude with a relatively smaller frequency

P

2

(Jenkins et al.

1974). It was also evident that multiple

P

1

type peaks followed

by the distinct

P

2

type peak often occurred. The multiple

P

1

peaks occurred when the drop hammer was not restrained

vertically, so consequently it rebounded after the first impact

and impacted the specimen again.

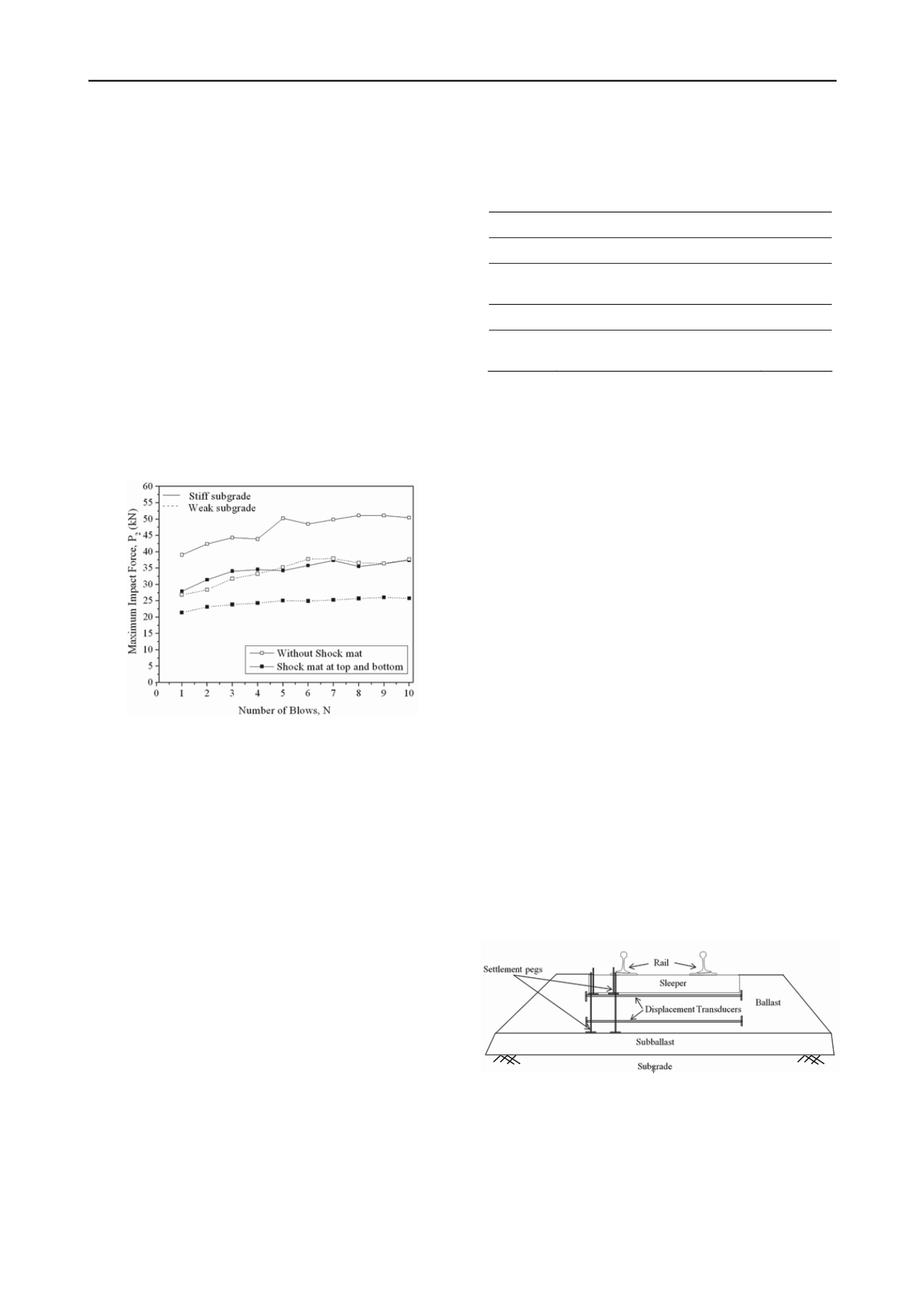

Figure 2. Variation of impact force with number of blows (data sourced

from Nimbalkar et al. 2012).

2.3

agnitude of impact force compared to a stiffer

, 2005, Lackenby et al. 2007, Indraratna and Nimbalkar

20

fo

ak sub

s that the weak subgrade itself

acts flexibl

Table 1. Ballas

ge under impact loading (Indraratna et al.,

2011a).

pe

Multiple impact loading

Figure 2 shows the variation of

P

2

force peak with repeated

hammer blows (

N

). The

P

2

force showed a gradual increase

with the increased number of blows due to the densification of

ballast. A dense aggregate matrix offers a higher inertial

resistance which leads to an increased value of

P

2

. Even without

a shock mat, a ballast bed on a weak subgrade leads to a

decreased m

subgrade.

2.4

Particle breakage

After each test, the ballast sample was sieved to obtain the

ballast breakage index (BBI) as shown in Table 1. The particle

breakage encountered under 10 impact blows was significantly

higher than that under both static and cyclic loads (Indraratna et

al. 1998

11).

The higher breakage of ballast particles can be attributed to

the considerable non-uniform stress concentrations occurring at

the corners of the sharp angular particles of fresh ballast under

high impact stresses. When a shock mat was placed above and

below the ballast bed, particle breakage was reduced by

approximately 47% for a stiff subgrade, and approximately 65%

r a we

as a

grade. This implie

e cushion.

t breaka

Base ty

Test Details

BBI

Stiff

Without shock mat

0.170

Stiff

Shock mat at top and bottom of

0.091

ballast

Weak

Without shock mat

0.080

Weak

Shock mat at top and bottom of

ballast

0.028

3 USE OF GEOSYNTHETICS FOR STABILISING A

BALLASTED TRACK: BULLI CASE STUDY

In order to investigate deformations of a

caused by train traffic, and the associat

multi-layer rail track

ed benefits of using

3.1

mposite layer were

the other two sections, fresh and

th a layer of geocomposite at the

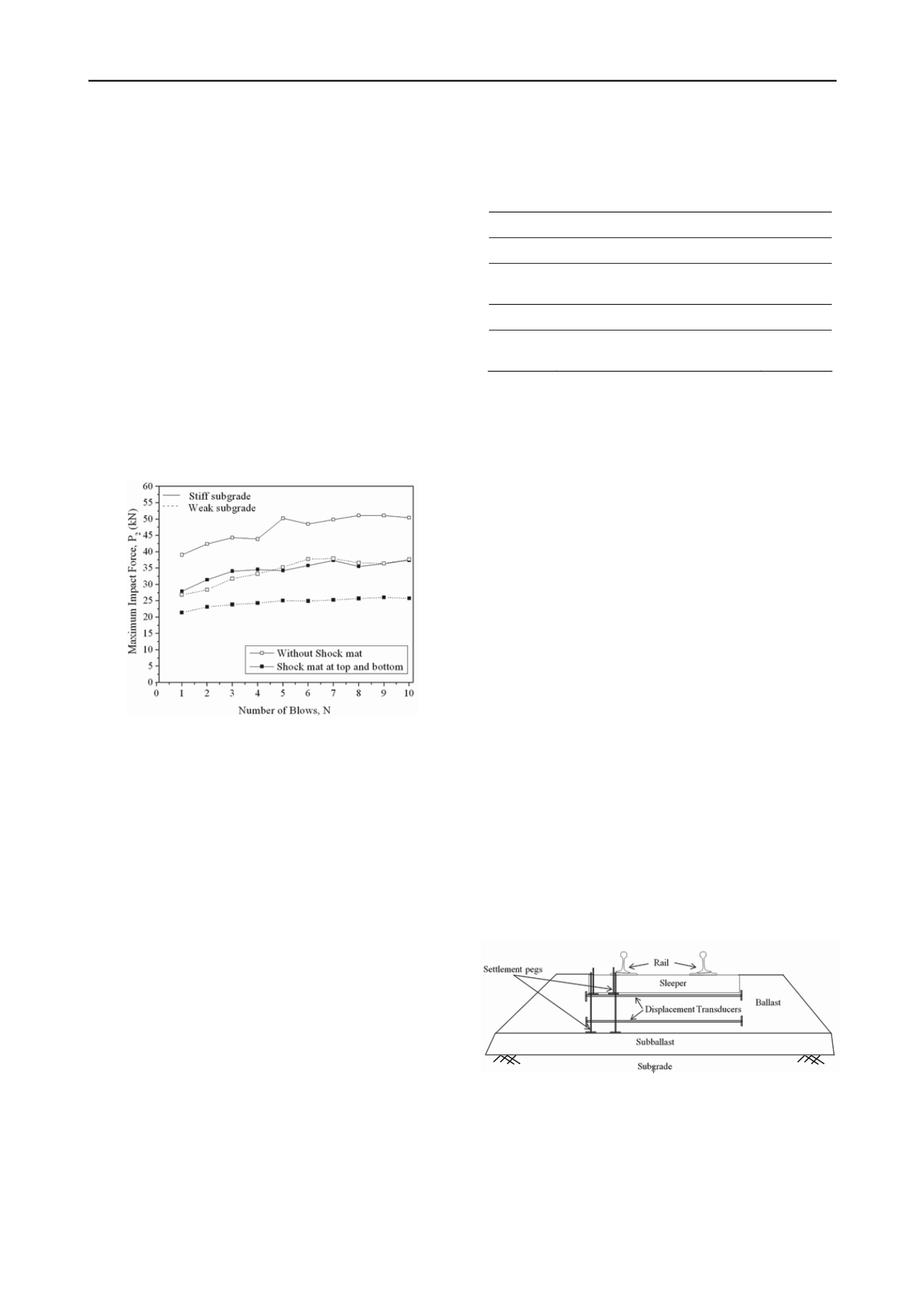

The vertical and horizontal stresses induced in the track bed were

measured by pressure cells. Vertical deformations of the track were

measured by settlement pegs, and lateral deformations were measured

by electronic displacement transducers. The settlement pegs and

displacement transducers were installed at the sleeper-ballast and

ballast-subballast interfaces, respectively, as shown in Figure 3.

geosynthetics in fresh and recycled ballast, a field trial was

carried out on a fully instrumented track in the town of Bulli

north of Wollongong City [Indraratna et al. 2009, 2010]. The

proposed site was located between two turnouts.

Site geology and track construction

A site investigation comprising 8 test pits and 8 Cone Penetrometer

tests was carried out to assess the condition of the sub-surface soil

profiles. The subgrade consisted of a stiff over consolidated silty clay

that showed high values of cone resistance (

q

c

) and friction ratio (

R

f

)

(Robertson 1990, Choudhury 2006).

The instrumented section of track was 60 m long and it was

divided into four equal sections. The layers of ballast and

subballast (capping) were 300 mm and 150 mm, respectively.

Fresh and recycled ballast without a geoco

used in two sections, while in

recycled ballast was used wi

ballast-subballast interface. The physical and technical

specifications of the fresh ballast, recycled ballast and

geosynthetic material used at this site have been reported

elsewhere (Indraratna et al. 2011a, 2012a).

3.2

Track instrumentation

Figure 3. Installation of settlement pegs and displacement transducers at

Bulli site (data sourced from Indraratna et al. 2012b)