1276

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

H

of 60 mm, mean diameter

D

50

of 0.21 mm, and uniform

coefficient

U

c

of 1.70

.

Reinforced roadbeds were introduced in Cases 3 and 4. A

Toyoura sand roadbed (

D

r

= 90%,

H

= 60 mm) was overlain by

an asphalt mixture layer in Case 3, and a Natom sand roadbed

(

D

r

= 95%,

H

= 60 mm) was overlain by the same asphalt

mixture layer in Case 4. The

D

50

of the Natom sand was 0.70

mm, and its

U

c

was 3.09. The 10 mm thick asphalt mixture was

composed of straight asphalt 80–100 and sands.

Table 1. Model ground conditions

Cyclic loadings were applied to the model grounds with

footing at a constant displacement rate of 0.05 mm/s. The

amplitude of the cyclic stress applied in Case 1 was 110 kN/m

2

;

that applied in Cases 2, 3, and 4 was 80 kN/m

2

. During the

cyclic loadings, consecutive images of the model grounds were

captured by a digital camera.

In each test, 100 cyclic loadings were first applied. Tie-

tamper repair modeling was performed in the following manner.

As shown in Fig. 2, the footing was reset to the initial position

after 100 cyclic loadings were applied. A small spoon was next

inserted into the model ground near lateral sides of the footing.

After the spoon reached a fixed ground depth, it was tilted

several times to permit the crushed stones to move laterally.

This procedure was followed at several locations until the voids

between the footing and the ground surface were completely

filled by the crushed stones. Finally, additional crushed stones

were introduced to the ground surface near the footing sides to

produce a flat ground surface. After this tie-tamper modeling

was implemented, 100 of cyclic loadings were applied again.

Figure 2. Tool and procedure used for simulating tie-tamper repair

3 RESIDUAL DEFORMATION CHARACTERISTICS

3.1 Effects of ballast thickness

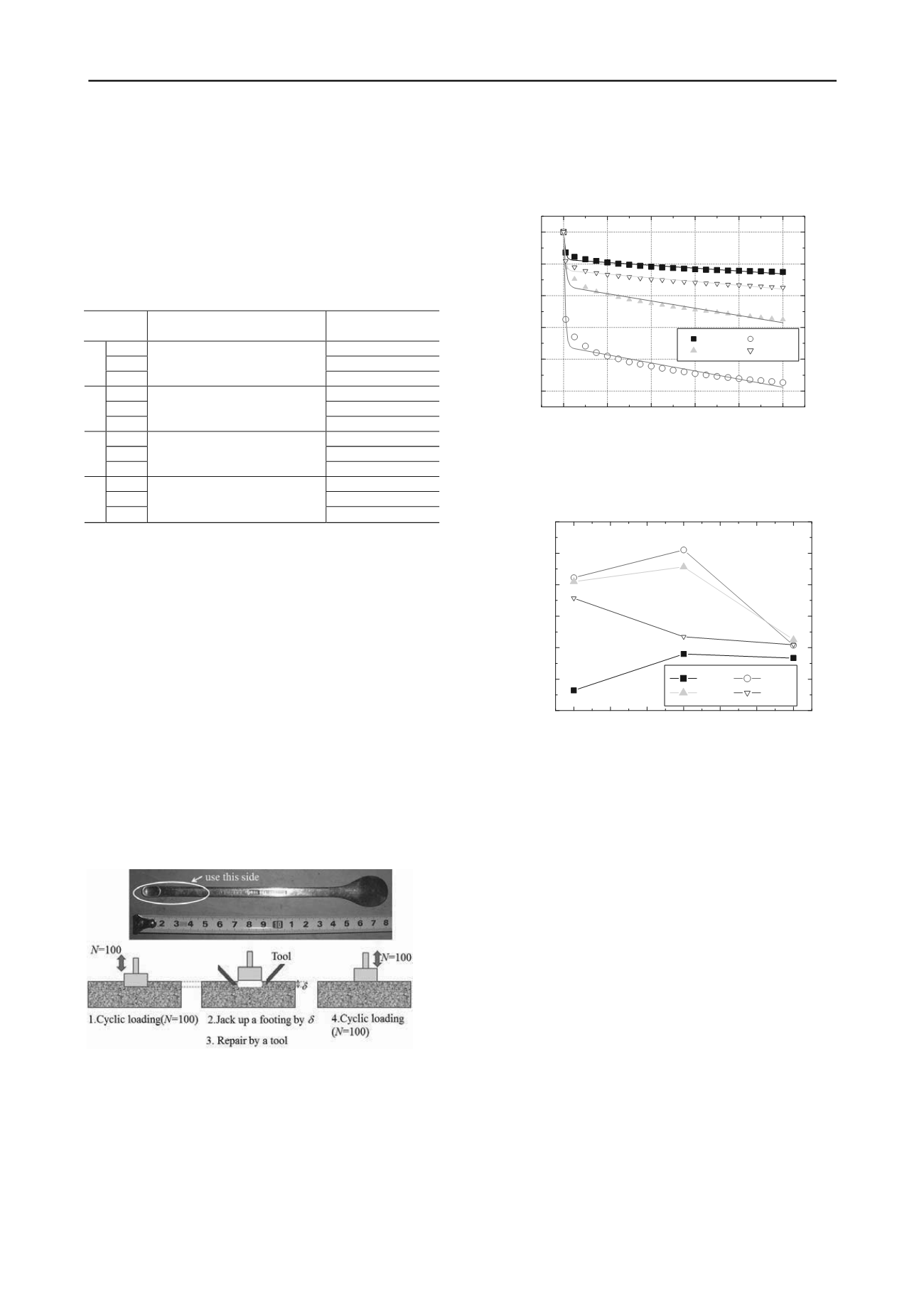

The relationships between the number of cyclic loadings

N

and

footing settlement

were obtained before and after tie-tamper

repair, as shown in Fig. 3. Each relationship obtained could be

fitted by the following equation

2)

:

N

e C

N

1

(1)

where

C

and

are parameters representing the initial settlement

process, and

represents the process of gradual subsidence.

0

20

40

60

80

100

10

8

6

4

2

0

Case1-2

Case2-2

Case3-2

Case4-2

H

b

=50mm

Number of cyclic loading ,

N

Settlement of footing

,

(mm)

Figure 3. Relationships between number of cyclic loading cycles and

footing settlement before tie-tamper implementation. Ballast thickness,

H

b

, = 50 mm

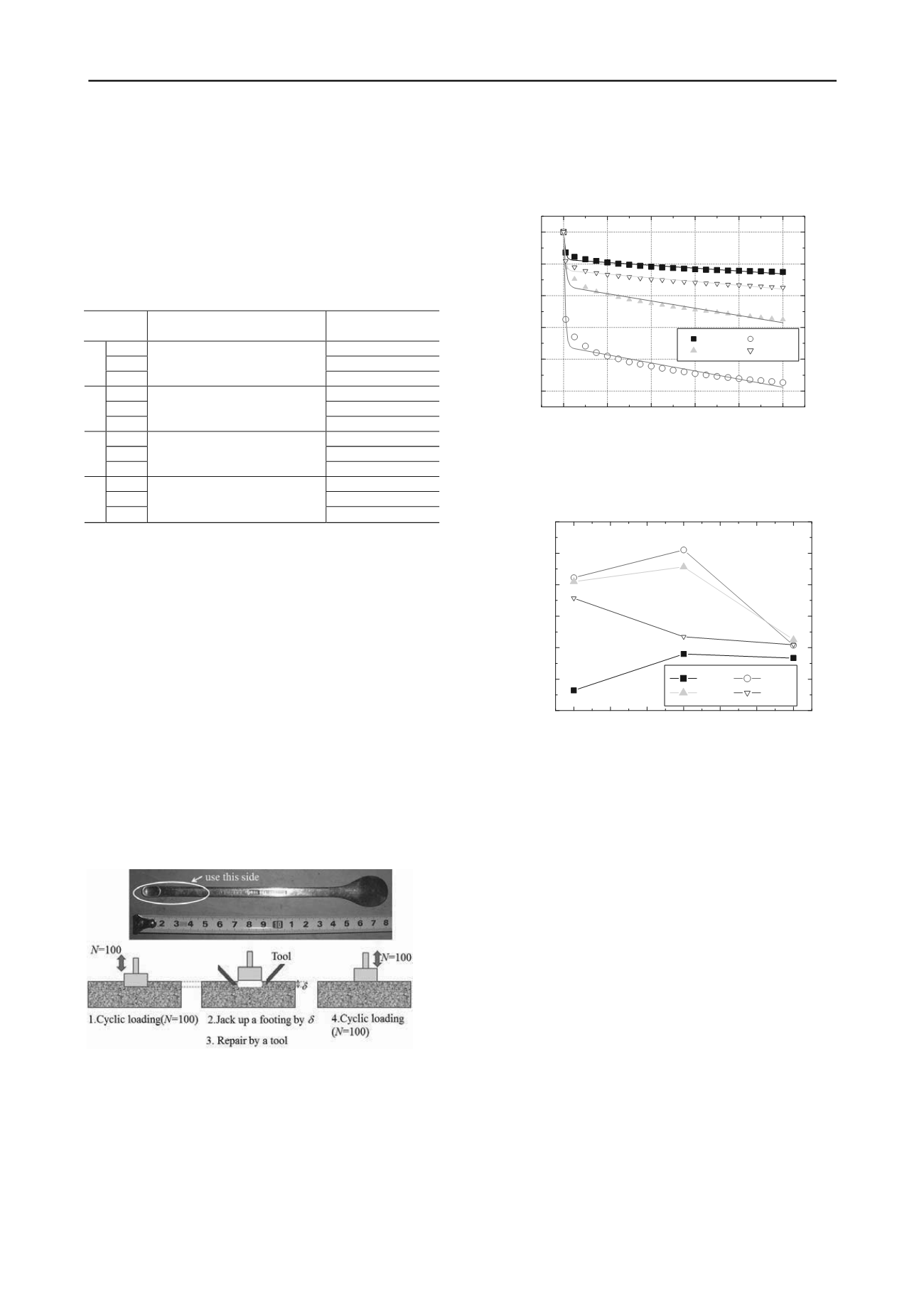

Figure 4. Relationships between gradual subsidence parameter

and

ballast thickness

H

b

before tie-tamper implementation

Figure 4 shows the relationships between the gradual

subsidence parameter

and ballast thickness

H

b

before tie-

tamper implementation. It should be noted that 50 mm

H

b

was

used to represent the 250 mm ballast thickness adopted for the

standard design because the model size was at a scale of one-

fifth. Interestingly, it is seen in the figure that

was highest

when

H

b

= 50 mm in Cases 2 and 3. High

values indicate a

substantial amount of gradual settlement; thus, these results

suggest that the standard ballast thickness of 250 mm is

ineffective for minimal settling.

The residual settlement characteristics were investigated in

detail with PIV analysis. First, the displacement magnitude and

direction of crushed stones and roadbeds induced by 100 cyclic

loadings were estimated by analyzing consecutive digital

images. The distributions of maximum shear strain

max

generated in the crushed stones and roadbeds were next

calculated. Figures 5 to 7 show the results obtained from Cases

1, 2, and 3. Results could not be obtained from Case 4 because

the monotonic color of dark gray Natom sand resulted in

ineffective pattern matching of PIV.

As shown in Fig. 5, a high value of

max

was noted in Cases

1-1 and 1-2 until the ground depth reached the bottom steel

plate. However, the concentration of

max

could not be observed

in Case 1-3 near the bottom steel plate. Similarly, the

concentration of

max

could not be observed in the roadbeds for

Cases 2-3 and 3-3, as shown in Figs. 6 and 7. These results

indicate that when

H

b

= 80 mm,

max

can be sustained in

Case No.

Roadbed

Ballast thickness

H

b

(mm)

1-1

20

1-2

50

1

1-3

Steel (Bottom plate of a sand

box)

80

2-1

20

2-2

50

2

2-3

Toyoura sand (

D

r

= 90%,

H

=

60 mm)

80

3-1

20

3-2

50

3

3-3

Toyoura sand (

D

r

= 90%,

H

=

60 mm) + Asphalt mixture

(layer thickness = 10 mm)

80

4-1

20

4-2

50

4

4-3

Natom sand (

D

r

= 95%,

H

= 60

mm) + Asphalt mixture (layer

thickness = 10 mm)

80

20 30 40 50 60 70 80

0.000

0.005

0.010

0.015

0.020

0.025

0.030

Case1

Case2

Case3

Case4

Ballast thickness,

H

b

(mm)