1021

Technical Committee 105 /

Comité technique 105

Vertical stress,

V

Horizonatl stress,

h

Horizonatl stress,

h

Pore pressure,

u

Rotation

fixities

Beam

elements

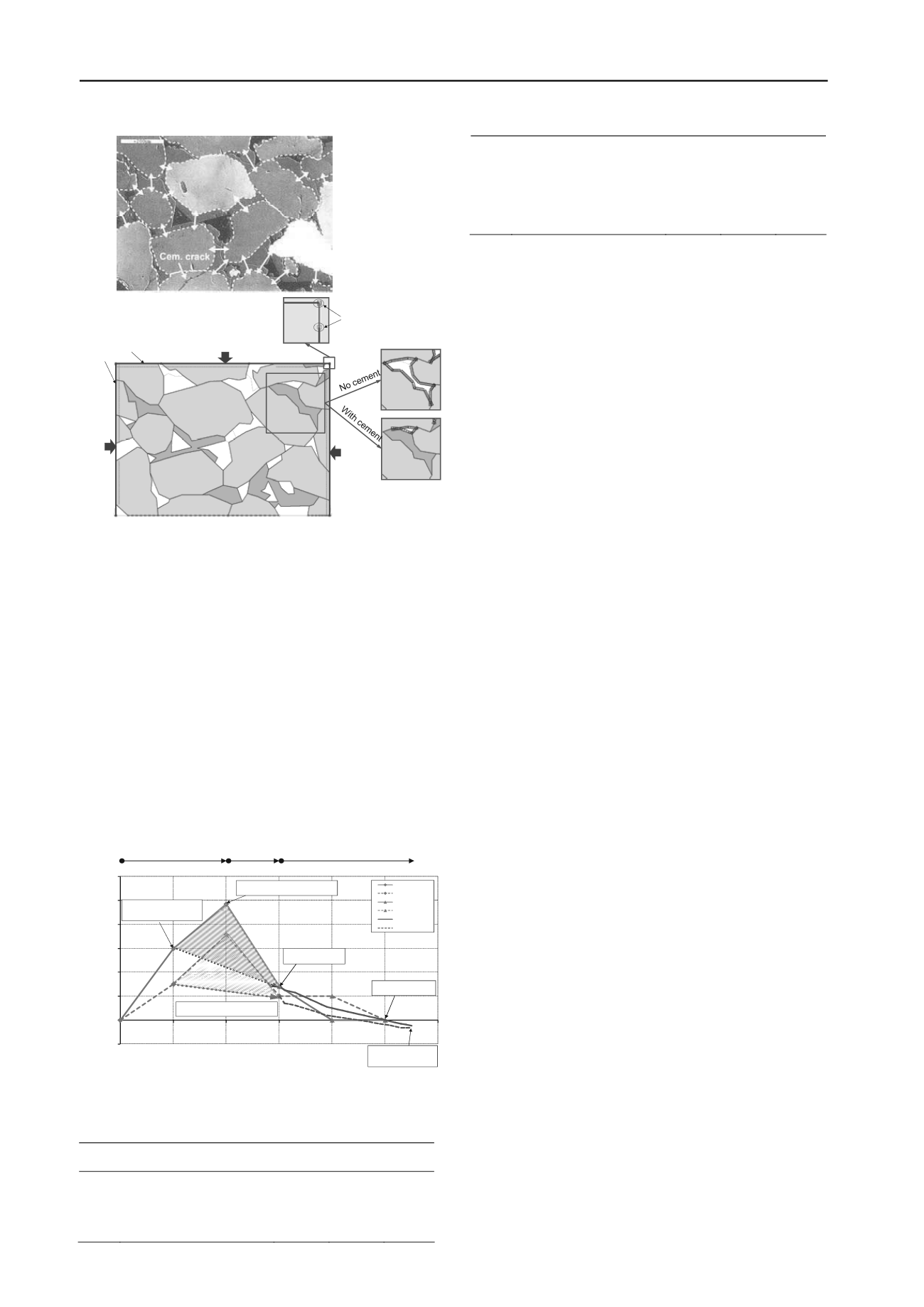

Figure 3. Cathodoluminescence SEM picture (top) from Storvoll (2004)

and equivalent 2D micro FE-model (bottom) used for studying

formation damage around wellbore during drilling and coring

operations.

Then in the second stage the stress changes obtained from

the macro FE-model are applied at the boundary of a micro FE-

model in order to investigate tensile fracturing on the micro

level. Figure 3 shows the FE-model established based on a high

resolution cathololuminescence SEM picture of well cemented

sandstone (from Storvoll, 2004), where authigenic quartz

cement can clearly be separated from the original grains. For the

deeply buried Field A which has undergone both mechanical

and chemical compaction the cemented areas were activated at a

stress condition corresponding to a burial depth of about 4.1 km

corresponding to depth for onset of quarts cementation at

temperatures of 70 - 80

0

C (Bjørlykke, 1989). Field B has

undergone purely mechanical compaction due to the shallow

burial depth (< 2.4 km), and no cement was applied for this

model.

-10

0

10

20

30

40

50

60

0

1

2

3

4

5

6

Effective stresses (MPa)

Loading step

Sig'_v

Sig'_h

Sig'_vCoring

Sig'_hCoring

Sig'_vDrilling

Sig'_tDrilling

Approximatestressat2500 m

beforequarts cementation

Assuming hydrostaticpressure

Maxpossiblestressat 4100 m TWD

Assuming hydrostaticporepressure

Final effectivestress

aftercoring and retrieval

Measured in-situ stress

at4100 m TVD

Uncertain stresspath

Porepressure history is not known

Final effectivestress in

formationafterdrilling and

temperature reduction

Coring and

drilling

Mechanical and

chemical compaction

Mechanical

compaction

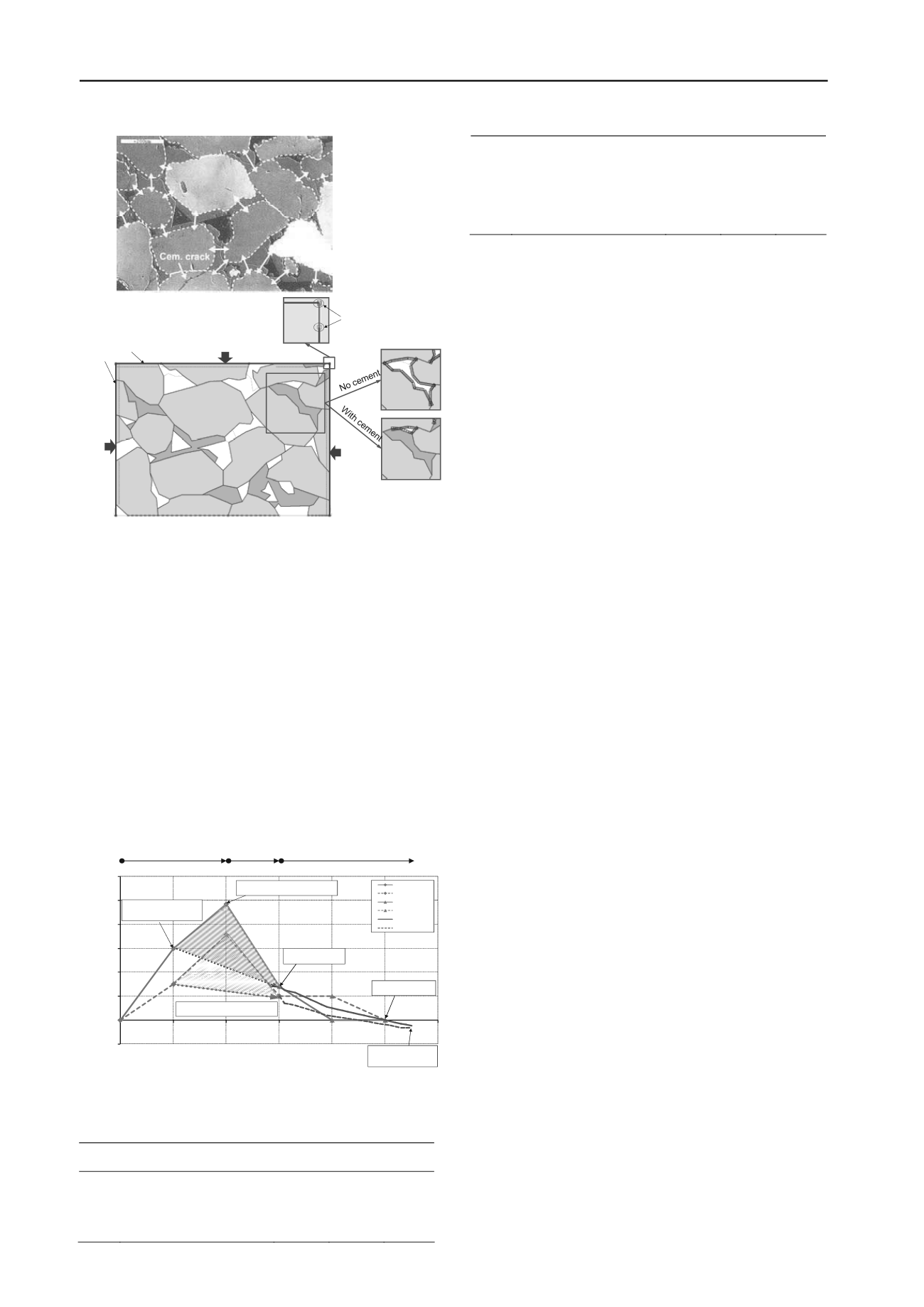

Figure 4. Idealized stress paths for Field A. Stress changes during

drilling and coring process are based on “macro” stresses released at

material point A plotted in Figure 5.

Table 2. Simplified burial history applied in micro FE-model.

Step Description

V

(MPa)

h

(MPa)

u

(MPa)

1

At 2500 m, no cement

55

40

25

2

At 4100 m, with cement

90

77

41

3

At 4100 m, in-situ state

90

85.8

75.8

4

Mud pressure & mud-flow

88.4

82.8

82.2

5

Temperature reduction (

0

C)

-

2.4

87.9

82.4

82.2

-

9.5

86.4

81.4

82.2

-

19.1

84.4

80.0

82.2

-

33.3

82.2

81.4

82.2

-

57.1

76.3

74.4

82.2

-

66.7

74.4

72.7

82.2

-

71.4

73.5

72.6

82.2

V

,

h

are total vertical and horizontal stresses, respectively

u is pore pressure

Figure 4 shows an idealized loading path being applied to the

micro FE-model at Field A. The stress changes during drilling

and coring processes are based on the “macro” stresses released

at the material Point A located at a distance of one radius into

the formation from the wellbore wall and two radius up from

the wellbore tip (see Figure 5). In the process of coring there is

first a total vertical stress unloading. This corresponds to

removing the weight of overburden during coring. Finally, the

horizontal stress is completely unloaded. This corresponds to a

situation after coring and core retrieval when pushing out the

core from the core cylinder. In the formation adjacent to the

wellbore the stress change is a combination of effect of pore

pressure changes, temperature effects and stresses from the

process of drilling. This is a complex process that requires FE

modelling. Therefore the final load step has been directly taken

from the calculated results of the macro FE-model. The

effective vertical and effective radial stresses at Point A after

drilling are shown in Figure 4. This includes unloading due to

mudflow into the formation and cooling of the formation. Note

that the final effective stresses shown in the figure corresponds

to a cooling of about 70

0

C, which is a higher temperature

reduction than experienced in the field. Also, the tangential

stress which is most critical with respect to micro fractures is

not shown in this figure. Table 2 summarizes the burial history

at Field A which is applied at the boundary of a micro FE-

model in order to investigate tensile fracturing on the micro

level.

3 RESULTS FROM MACRO FE-MODEL

From the results of the 3D modelling in it is found that at a

distance of one radius from the wellbore wall the application of

the drill bit forces gives minor effect in terms of stress changes

compared to the effects from mud pressure, mud-fluid flowing

into the formation and temperature reduction. In fact, damage

only occurs very locally at the edges of the gauge pads and

drilling cutters. Since the effects from the drill bit can be

neglected, for a matter of modelling simplification and also to

minimize the time necessary for processing, a macro

axisymmetric FE-model has been established and used for

studying the other effects with respect to the wellbore damage.

Figure 5 shows that the macro (continuum) analysis predicts

tensile fracturing within one radius into the formation (point A)

after circa 67

0

C of cooling. This value is not in agreement with

field observations which indicate fracturing at much lower

temperature differences as observed from the Radial Dipole

Profiling data. Hence a further evaluation of tensile fracturing

on a micro level was performed with a 2D micro FE-model

(grain scale).

4 RESULTS FROM MICRO FE-MODEL

In both the Field A and the Field B case, it is found that onset

and development of tensile fractures starts at a lower

temperature reduction in the micro FE-model (Figure 6) then in

the macro FE-model (see Figure 5). The micro FE-model thus

seems to pick up formation damage that cannot be found when

applying a macro FE-model, and this model is closer to explain

the observed potential stiffness reduction based on the

difference between the mud temperature and the formation

temperature of 25-35

0

C as indicated from downhole

temperature log. There are however limitations in the 2D micro

model and the results should only be used as a indications of