1018

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

4 SIMULATION RESULTS

The simulation was conducted on four specimens at

S

Hb

= 0%,

15%, 24% and 41% at a pore water pressure of 8 MPa and a

temperature of 5C in order to compare to the experimental data

published in Masui et al. (2005).

S

Hp

is assumed to be

approximately 26% according to the data in Masui et al. (2005).

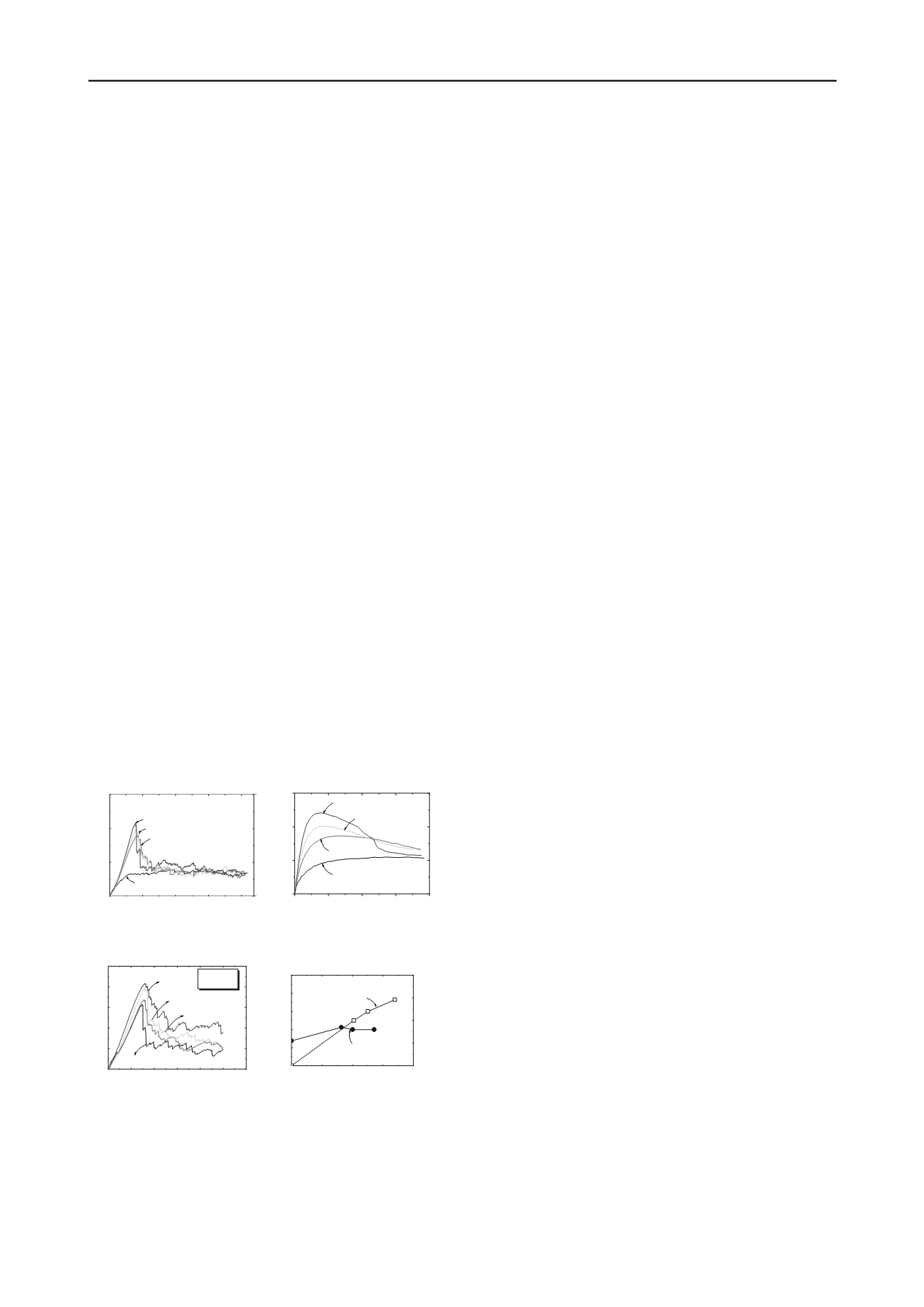

Fig. 8 shows the simulated stress-strain response at an

effective confining pressure of 1 MPa and test results obtained

under the same conditions. Although the simulation can not

quantitatively reproduce the tests, it captures the essential

features such as strain softening at

S

H

> 26%. At higher

S

H

, the

peak strength is mobilized when the axial strain exceeds

approximately 3%, and the residual strength coincides at a large

strain regardless of hydrate saturation due to complete breakage

of hydrate bonds. This agrees well with experimental data.

However the peak deviator stress obtained from the simulation

is lower than the test results. Besides the difference between

biaxial and triaxial tests, one of the reasons is that the bond

tension and compression strength could be underestimated in

the model. The size of the specimen used in material strength

tests is much larger than inter-particle bonds in MHBS. The

strength measured from a large specimen is much lower than

that of a much smaller specimen.

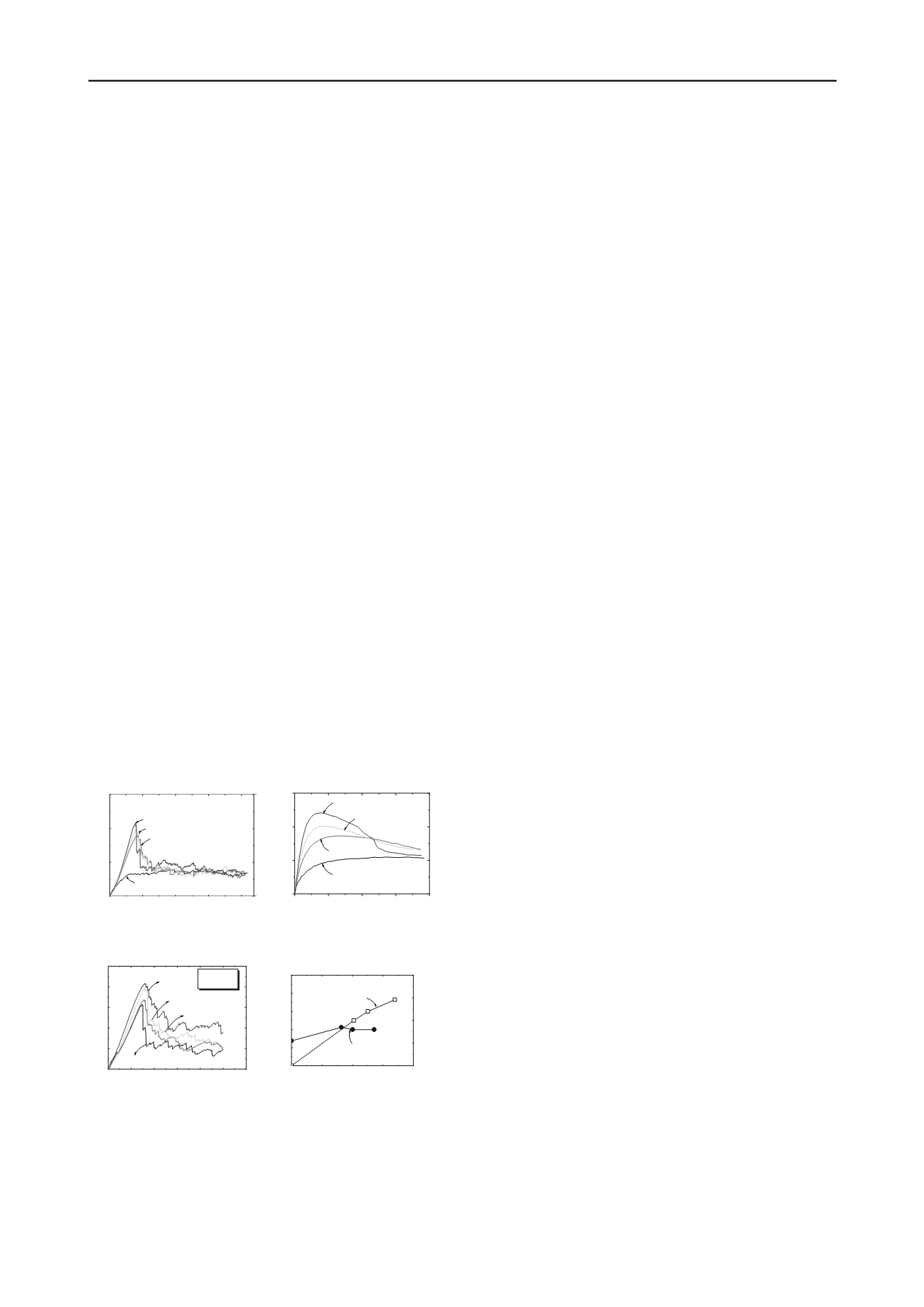

Fig. 9(a) presents an example of the stress-strain behavior

under different confining pressures, which leads to a

relationship between the peak strength parameters and

S

H

as

depicted in Fig. 9(b). The presence of hydrate cause the increase

in cohesion, while no significant change in the internal friction

angle is found associated with increasing

S

H

. This agrees well

with the experimental observation (Masui et al. 2005). However

the friction angle obtained from the simulation (approximately

20) is lower than the test data (approximately 30). This could

be improved by introducing the inter-particle rolling resistance

in the model. The micro parameters associated with the rolling

resistance can be first calibrated from a simulation on a

specimen without MH bonds in order to reach high friction

angle. These parameters set are then brought into MHBS model.

Considering the inter-particle rolling resistance will result in a

higher peak deviator stress, which better matches the test data as

shown in Fig. 8(b).

0

4

8

12 16

0

1

2

3

S

=67%

0-26%

40%

50%

Deviator Stress

(

MPa

)

Axial Strain

(

%

)

(a)

0

4

8

12

16

0

3

6

9

26.4%

40.9%

50.1%

Deviator stress (MPa)

Axial strain (%)

S

H

=67.8%

(b)

Figure 8. Deviator stress vs. axial strain: (a) DEM simulation; and (b)

triaxial test results performed by Masui et al. (2005)

0 2 4 6 8 10 1

0.0

0.5

1.0

1.5

2.0

2.5

2

S

H

=50%

0.7MPa

0.52MPa

1.1MPa

Deviator stress

(

MPa

)

Axial strain (%)

1.5MPa

(a)

0 20 40 60 80

0.0

0.2

0.4

0.6

0.8

1.0

16

18

20

22

24

Cohesion

Friction angle

(

o

)

Cohesion

(

MPa

)

S

H

(

%

)

Friction angle

(b)

Figure 9. Simulation result (a) deviator stress vs. axial strain at different

confining pressure for a specimen with SH=50%; and (b) peak strength

parameters at different SH.

5 CONCLUSIONS

This paper proposed a two-dimensional bond contact model of

MHBS for considering the bonding effect of MH. The bond

strength envelope was partially derived from laboratory data.

The model parameters are related to the hydrate saturation,

confining pressure, temperature and density of MH. Using this

model, the DEM simulation of the biaxial test is capable of

capturing the major mechanical response of MHBS specimen

such as strain softening and shear dilation at high hydrate

saturation. This study can help to better understand the

connection of the microscopic formation habit of MH to

macroscopic mechanical behaviors of MHBS.

Though the DEM simulation produced results qualitatively

comparable to available test data, quantitative agreement

remains still a challenge. The current model ignores the bond

thickness, which however affects the hydrate saturation and the

bond strength parameters. Consideration of inter-particle rolling

resistance in the model will improve the model performance.

Moreover, the size effect on the bond strength remains unclear

and deserves more caution. Further investigation on these issues

is definitely needed in the future work.

ACKNOWLEDGEMENTS

This work is funded by China National Funds for Distinguished Young

Scientists (No. 51025932), and the EU FP7 IRSES grant (No. 294976).

REFERENCES

Brugada J. et al. 2010. Discrete element modelling of geomechanical

behaviour of methane hydrate soils with pore-filling hydrate

distribution.

Granular Matter

12(5, SI): 517-525.

Cundall P.A. and Strack O.D.L. 1979. A discrete numerical model for

granular assemblies.

Géotechnique

29(1), 47–65.

Ellyin F. and Xia Z.H. 2006. Nonlinear viscoelastic constitutive model

for thermoset polymers.

Journal of Engineering Materials and

Technology

128:579-585.

Hussein A. and Marzouk H. 2000. Behavior of high-strength concrete

under biaxial stresses.

ACI Materials Journal

97(1):27-36.

Hyodo M. et al. 2005. Basic research on the mechanical bahavior of

methane hydrate-sediments mixture.

Japanese Geotechnical Society

45(1):75-85.

Jiang M.J. et al. 2003. An efficient technique for generating

homogeneous specimens for DEM studies.

Computers and

Geotechnics

30(7): 579-597.

Jiang M.J. et al. 2012a. Contact behavior of idealized granules bonded

in two different interparticle distances: An experimental

investigation.

Mechanics of Materials

55: 1-15.

Jiang M.J. et al. 2012b. An experimental investigation on the

mechanical behavior between cemented granule,

Geotechnical

Testing Journal

(

ASTM

) 35(5): 678-690.

Jiang M.J. et al. 2006. Bond rolling resistance and its effect on yielding

of bonded granulates by DEM analyses.

International Journal for

Numerical and Analytical Methods in Geomechanics

30(8): 723-

761.

Jung J. et al. 2012. Stress-strain response of hydrate-bearing sands:

Numerical study using discrete element method simulations.

Journal of Geophysical Research-Solid Earth, 117, B04202,

doi:10.1029/2011JB009040.

Kupfer H. et al. 1969. Behavior of concrete under biaxial repeated

loading.

ACI Journal Proceedings

66(52): 656-666.

Kvenvolden K.A. 1988. Methane hydrate-a major reservoir of carbon in

the shallow geosphere?

Chemical Geology

71(1-3):41-51.

Masui A. et al. 2005. Effects of methane hydrate formation on shear

strength of synthetic methane hydrate sediments.

Proceedings of

the 5th International Offshore and Polar Engineering Conference

,

Seoul, Korea: 364-369.

Nadreau J.P. and Michel B. 1986. Yield and failure envelope for ice

under multiaxial compressive stresses.

Cold Regions Science and

Technology

13:75-82.

Waite W.F. et al. 2009. Physical properties of hydrate-bearing soils.

Reviews of Geophysics

47, RG4003:1-38.