1009

Technical Committee 105 /

Comité technique 105

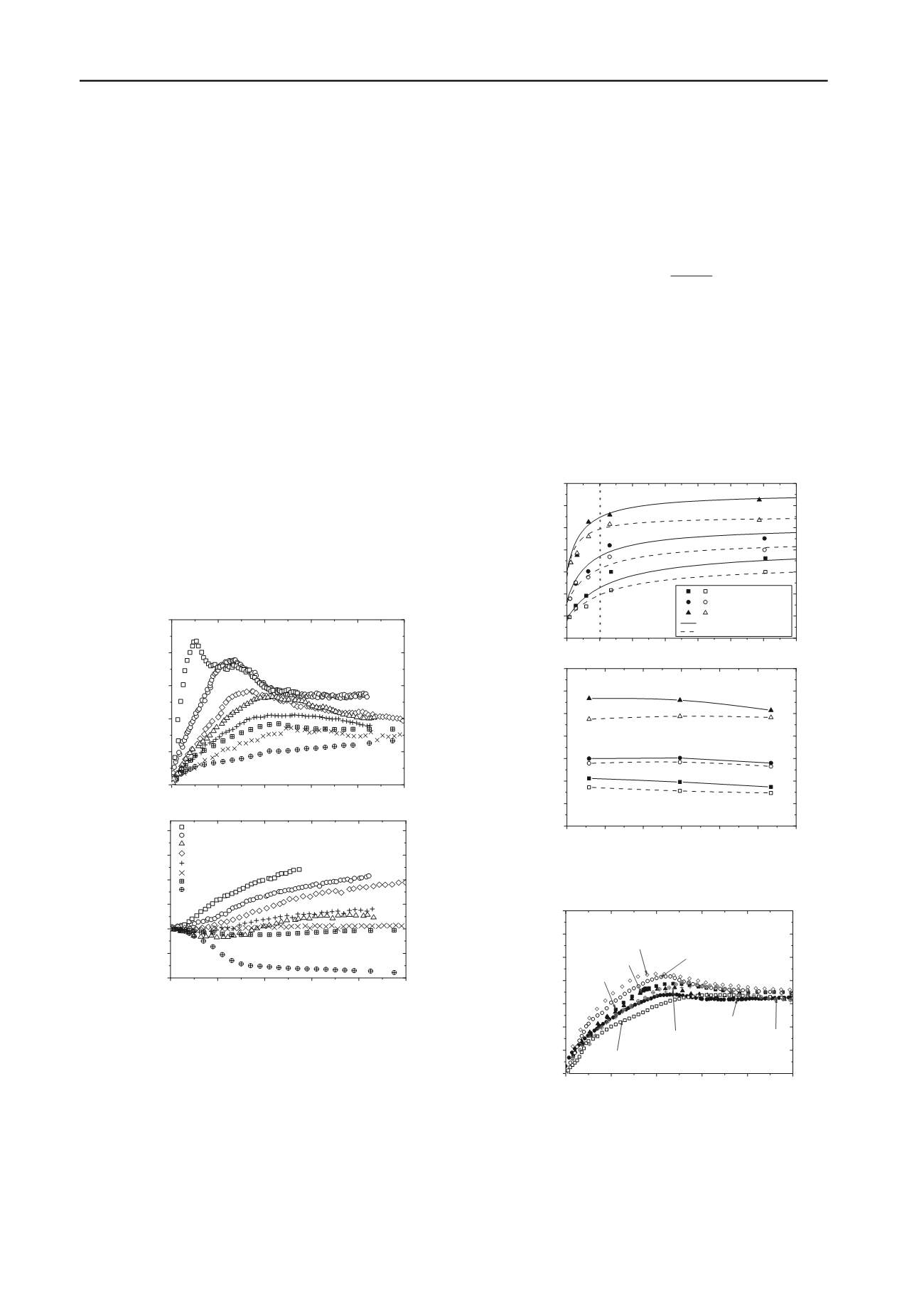

suction in a non-linear fashion, the rate of increase seems to

gradually decrease with increasing suction. Moreover, the

envelopes seem to suggest the existence of a critical suction

value, after which shear strength increase with suction is not

very significant. For this particular study this value seems to be

at suction of 100kPa, which corresponds to approximately

11.3% water content. It is interesting to note that the difference

between the peak and ultimate shear strength envelopes

increases with the applied vertical stress. This difference is

probably due to the larger reduction in void ratio attained at the

end of the compression stage for the specimens tested with

higher vertical stresses. At the beginning of the test, these

specimens have denser particle arrangement and would likely

experience a more pronounced softening behaviour that in turn

causes larger differences between the peak and ultimate shear

strength. In figure 5 (b) the peak and ultimate shear strength

data of specimens prepared at approximately the same water

content is represented with the level of compaction energy. The

peak shear strength seems to decrease with increasing energy

while ultimate shear strength is less affected. This difference

may be attributed to the fact that initial soil structure is being

erased during shearing. The differences in peak shear strength

are then probably associated with the difference in soil

structure, particularly when the line of optima is exceeded

(Figure 1, i.e. Kodikara, 2012). In addition, the specimens for

whom the compaction end states are located on the wet side of

the compaction plane may have experienced during compaction

larger pore water pressures that were quickly dissipated. This in

conjunction with the change in structure may contribute to the

deterioration of the soil strength; however, further confirmation

of this hypothesis is desirable.

0

2

4

6

8

0

20

40

60

80

100

10

Shear stress,

(kPa)

Horizontal displacement,

x (mm)

(a)

0

2

4

6

8

-1.0

-0.5

0.0

0.5

1.0

1.5

2.0

10

w

= 8.5%

w

= 10.5%

w

= 12.8%

w

= 12.6% (356kJ/m

3

)

w

= 13.0% (834kJ/m

3

)

w

= 14.0% (834kJ/m

3

)

w

= 14.1%

w

= 16.8%

Vertical displacement,

y (mm)

Horizontal displacement,

x (mm)

(b)

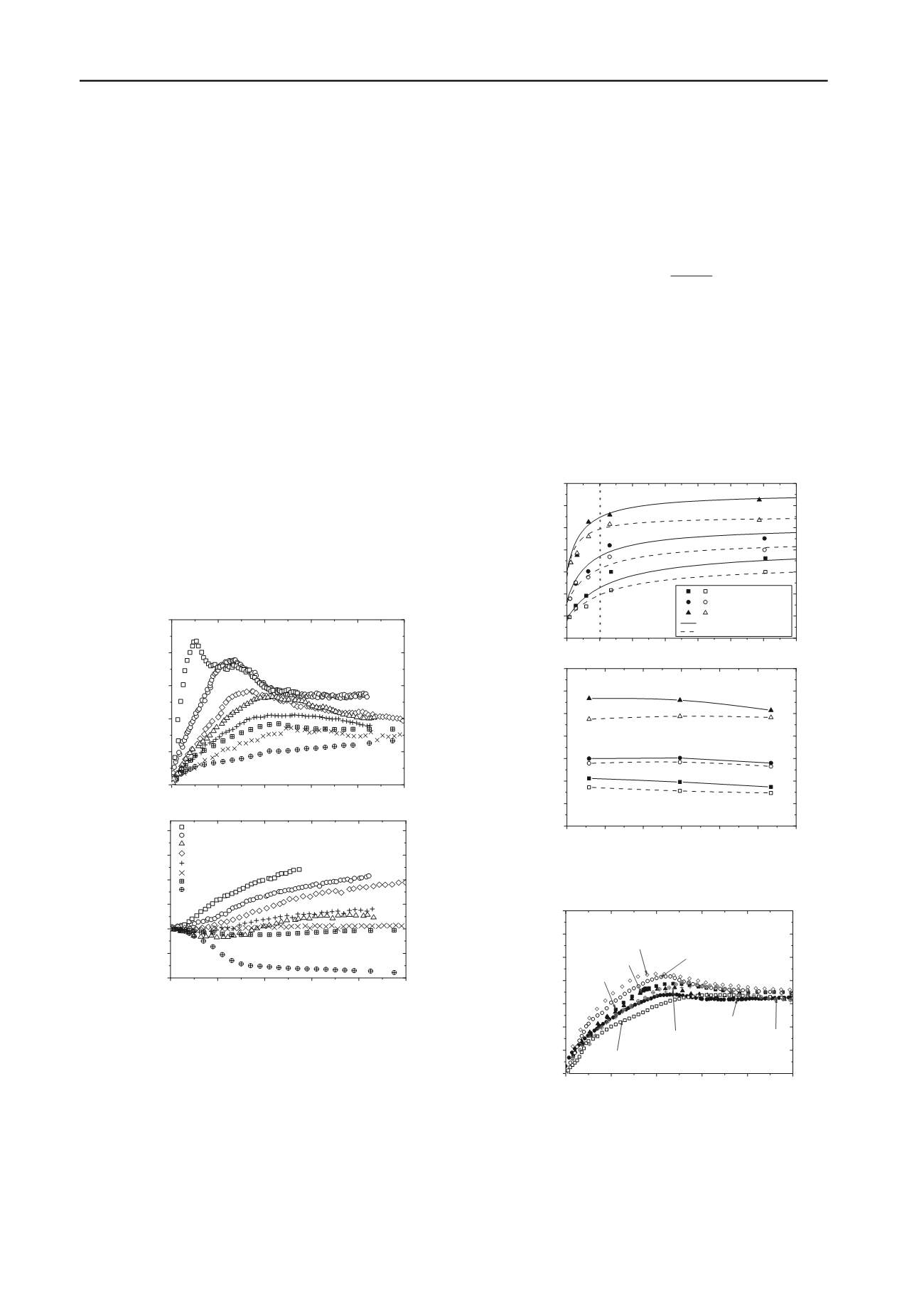

Figure 4. Shear tests results for an applied vertical stress of 38.4kpa in

terms of (a) shear stress and (b) vertical displacement.(w =8.5

16.8%

and E=358, 596 and 834kJ/m

3

)

3.2.2

Ultimate shear states

The ultimate shear state results were modelled using two

different approaches, namely, (a) the average skeleton stress

(Tarantino and Tombolato, 2005) and (b) critical stress ratios

(Toll and Ong 2003). Both approaches make reference to the

saturated states which were found to be relatively independent

of the compaction characteristics (Figure 6). Saturated tests

were only conducted for specimens compacted at 12.5%, given

the similarities of stress-strain behaviour between the saturated

specimens and as-compacted specimens that reached saturation

conditions during compression and shearing.

The average skeleton approach is based on the assumption

that the water menisci have a negligible effect on the ultimate

shear strength. The shear strength,

, is given by considering

the shear strength of saturated states at the same average

skeleton stress

sat

and the degree of saturation of the

macropores, or S

rm

, as follows:

w wm

sat

v

rm sat

v

wm

e e

sS

s

e e

(3)

where

e

w

and

e

are the water ratio (

e

w

=e

S

r

) and void ratio,

respectively, and

e

wm

is the microstructural water ratio. The

value of

e

wm

adopted is 0.237 and it was found by the least

squares method fitting of Eq. (3). Figure 7 (a) shows the

comparison between the measured and predicted ultimate shear

strength for all specimens, considering the average skeleton

stress defined in terms of

S

r

and

S

rm

. The prediction of shear

stress is favoured by the adoption of the

S

rm

instead of

S

r

.

Similar observations were reported by Tarantino and Tombolato

(2005) for statically compacted kaolin, despite the fact that the

fabric considered was mainly representative of the dry side of

optimum.

0

100 200 300 400 500 600 700

0

25

50

75

100

125

150

175

(a)

,

v

=38.4kPa

,

v

=79.5kPa

,

v

=146.7kPa

Peak shear strength envelopes

Ultimate shear strength envelopes

Shear stress,

(kPa)

Matric suction, s (kPa)

300

400

500

600

700

800

900

0

25

50

75

100

125

150

175

(b)

Shear stress,

(kPa)

Compaction energy, E (kJ/m

3

)

Figure 5. Shear strength envelopes for specimens compacted at (a)

energy level of 596kJ/m

3

and (b) w=12.8

13% (close and open symbols

represent peak and ultimate states, respectively).

0

2

4

6

8

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

10

AC-14.1(38.4)

AC 14.0(38.4)

AC-14.1(79.5)

AC-13.0(146.7)

AC-12.8(146.7)

sat-12.5(146.7)

sat-12.5(79.5)

sat-12.5(38.4)

Stress ratio ,

v

Horizontal displacement,

x (mm)

AC: As-compacted CWDST

Numbers in brackets represent vertical pressures

Figure 6. Stress ratio with horizontal displacement for saturated

drained tests (w

c

=12.5%, solid symbols) and constant water content test

at high

S

r

(open symbols).

In contrast, in the critical stress ratio approach the

contribution of the total stress and suction to the shear strength

is considered separately (Toll and Ong, 2003). The soil fabric

changes are reflected in the variation of two individual stress

ratios governed by the degree of saturation. Toll and Ong