1011

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

SHEAR STRENGTH AND DEFORMATION OF METHANE HYDRATE BEARING

SAND WITH FINES

Résistance au cisaillement et déformation des sables avec des fines contenant

de l’hydrate de

méthane

M. Hyodo, N. Yoshimoto & A. Kato

Yamaguchi University, Ube, Japan

J. Yoneda

The National Institute of Advanced Industrial Science and Technology, Tsukuba, Japan

ABSTRACT: A series of triaxial tests has been carried out to determine the mechanical properties and dissociation characteristics of

sands with fines containing methane hydrate, using an innovative high pressure apparatus which has been developed to reproduce the

in-situ conditions expected during proposed methane extraction methods. It was found that the strength of MH sand increased with

MH saturation due to particle bonding and that the bonding effect was particularly dependent on the grain size of the host sand. A

high pressure and low temperature plane strain testing apparatus was also developed for visualizing the deformation of methane

hydrate bearing sand due to methane hydrate production. Using this testing apparatus, plane strain compression and methane hydrate

dissociation by depressurization tests were performed with the measurement of localized deformation.

RÉSUMÉ: Une série d'essais triaxiaux ont été effectués pour déterminer les propriétés mécaniques et les caractéristiques de

dissociation des sables avec des fines contenant du hydrate de méthane (MH), en utilisant un appareil innovant de haute pression qui

a été développé pour reproduire les conditions in-situ attendues pour des méthodes proposées d'extraction du méthane. Il a été

constaté que la résistance du sable avec MH augmente avec la saturation du MH due au collage des particules et que l'effet de collage

est particulièrement dépendant de la granulométrie du sable. Un appareil d'essai à haute pression et basse température en contraintes

planes a aussi été développé pour la visualisation de la déformation du sable contenant des hydrates de méthane grâce à la production

de méthane hydraté. En utilisant cet appareil, des essais de compression en contraintes planes et de dissociation des hydrates de

méthane par dépressurisation ont été effectués avec la mesure de la déformation locale.

KEYWORDS: metane hydrate, sand, fines, temperature, high stress triaxial test, high stress plane strain test, local deformation

1 INTRODUCTION

Recently there has been much research into Methane

Hydrate (referred to as MH hereafter) in the deep seabed as a

developable material. In Japan, an MH rich layer was found in

the Nankai Trough and production tests will be performed from

2013 (MH21 Research Consortium, 2012). MH in the deep sea

bed can exist at certain water pressure and temperature

conditions. It exists in the pore space of the sand, bonding the

sand particles. The MH rich layer is located around 100m-300m

from the seabed, in deep seas with depths of over 1000m. As

MH exists in uncemented sand sediments, there are many

geotechnical-engineering related problems in order to confirm

the stability of the production well and the grounds in its

vicinity (Yamamoto. K. 2009). Hyodo, et al. (2008) developed

temperature-controlled high-stress triaxial compression testing

apparatus, and used this to perform a series of shear tests on not

only undisturbed MH bearing sand samples from Nankai

Trough, but also artificially produced MH in Toyoura sand to

investigate the variation of shear strength due to cementation of

MH. In this study, specimens of sand with fines were prepared

to simulate the sediments in Nankai Trough and MH was

produced with various degree of MH saturation in the

specimens. A series of triaxial tests was performed and a newly

developed high-stress plane strain shear testing apparatus with

an observation window was used to investigate the global and

local deformation of MH bearing sand.

2 MATERIALS USED IN EXPERIMENTS

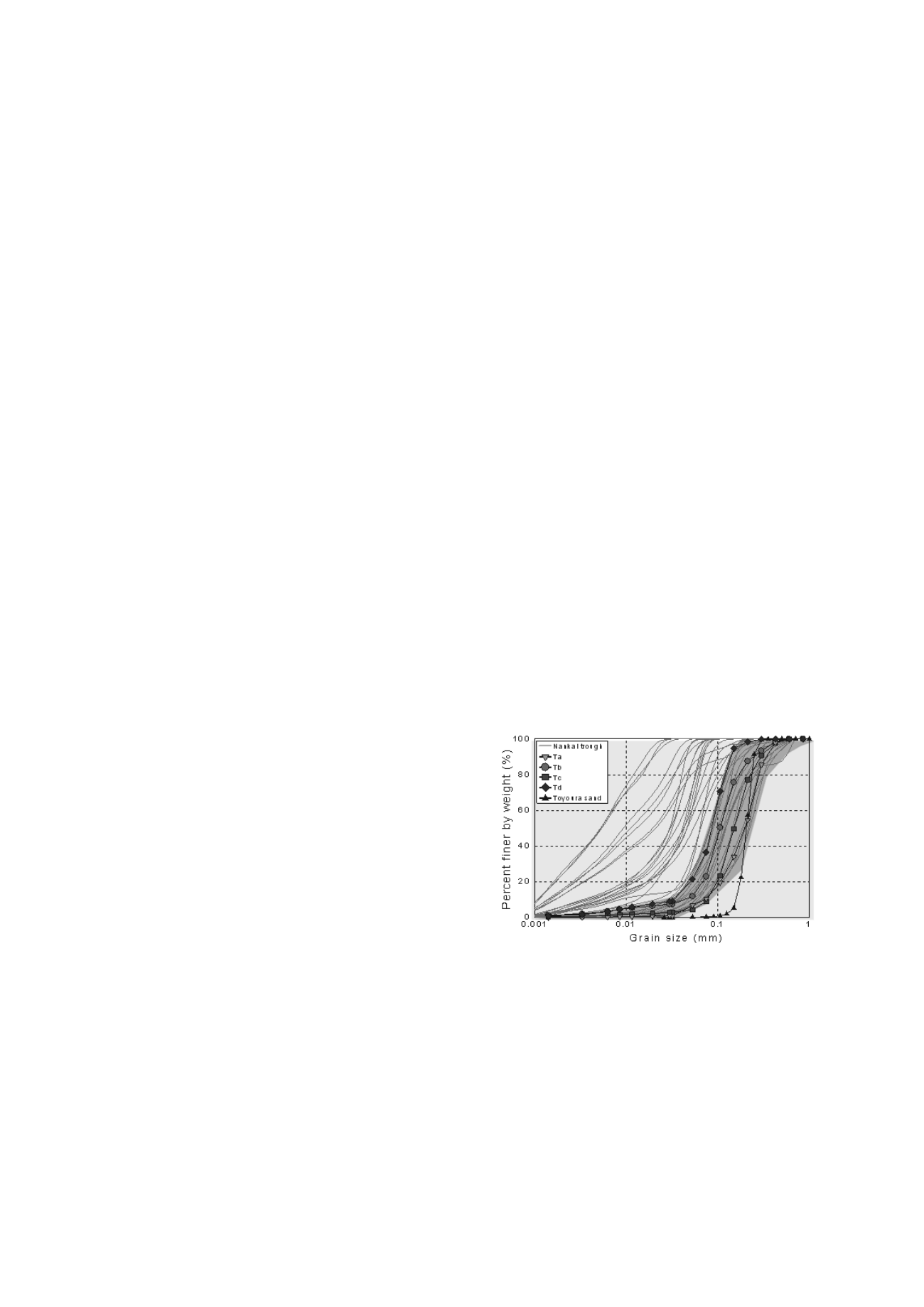

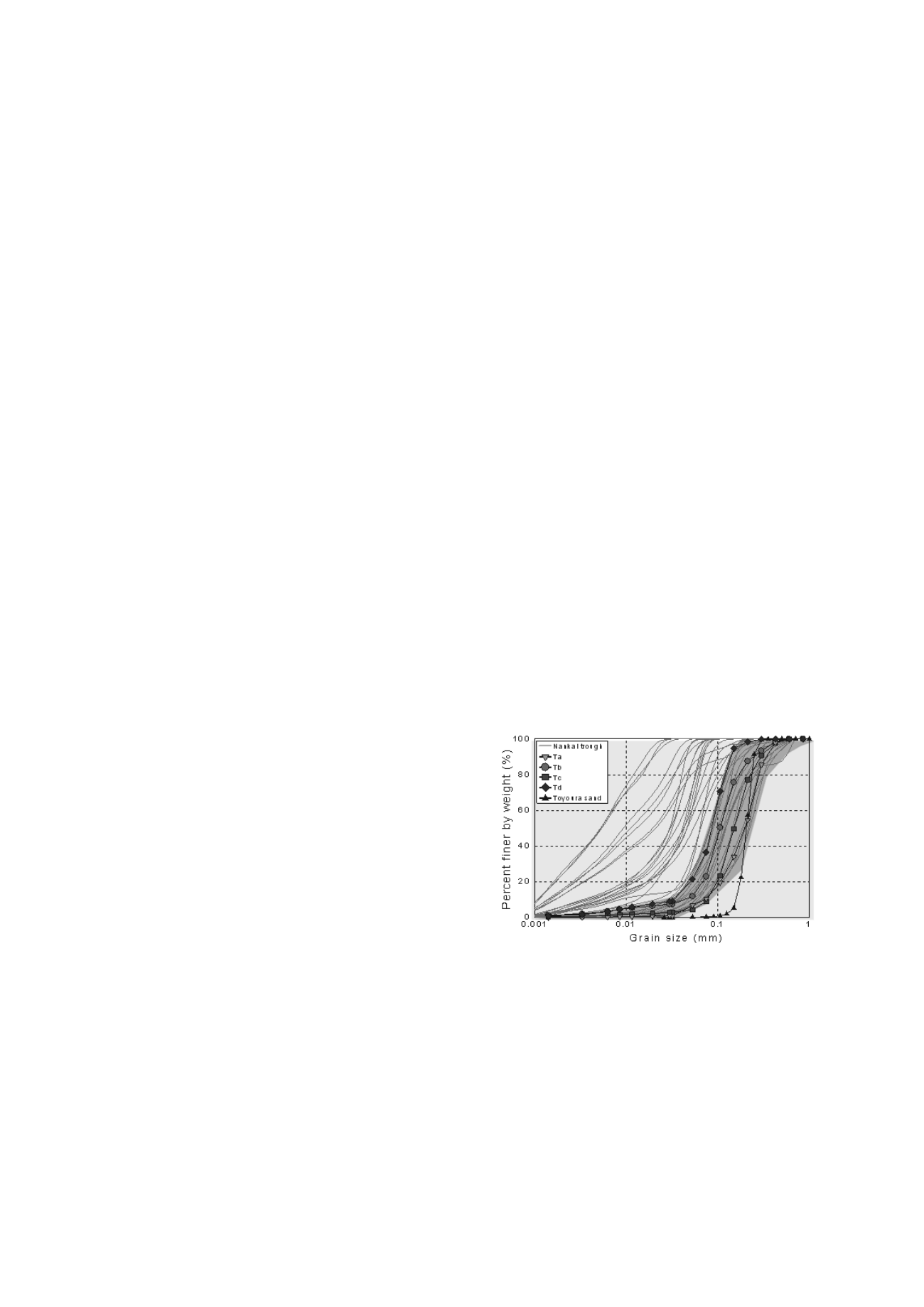

Grain size distribution curves for samples from Nankai Trough

and the simulation materials prepared in this study are shown in

Figure 1. The sediments in Nankai Trough`s seabed soil

constitute turbidite and show stratified layers with wide grain

distribution curves, with contents ranging from sand to clay.

The grain size distribution for the MH rich layer in Nankai

Trough is shown in grey; it is mostly sand with fines content. In

order to simulate the grain size distribution and minerals of this

layer, silica sand, kaolin and mica were mixed and four kinds of

simulated sands T

a

, T

b

, T

c

, T

d

were prepared as host sands. The

fines content increases in order of T

b

, T

a

, T

c

, T

d

and the mean

particle size decreases in order of T

a

, T

b

, T

c

, T

d

.

3 SHEAR CHARACTERISTICS OF MH BEARING SANDS

BY TEMPERATURE-CONTROLLED HIGH-STRESS

TRIAXIAL TESTING

Figure 1 Grain size distribution curves (Nankai trough and

artificial samples)

Shear Strength and Deformation of Methane Hydrate Bearing Sand with Fines

Résistance au cisaillement et déformation des sables avec des fines contenant de l’hydrate de

méthane

Hyodo M., Yoshimoto N., Kato A.

Yanaguchi Universit, Ube, Japan

Yoneda J.

The National Institute of Advanced Industrial Science and Technology, Tsukuba, Japan