1020

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

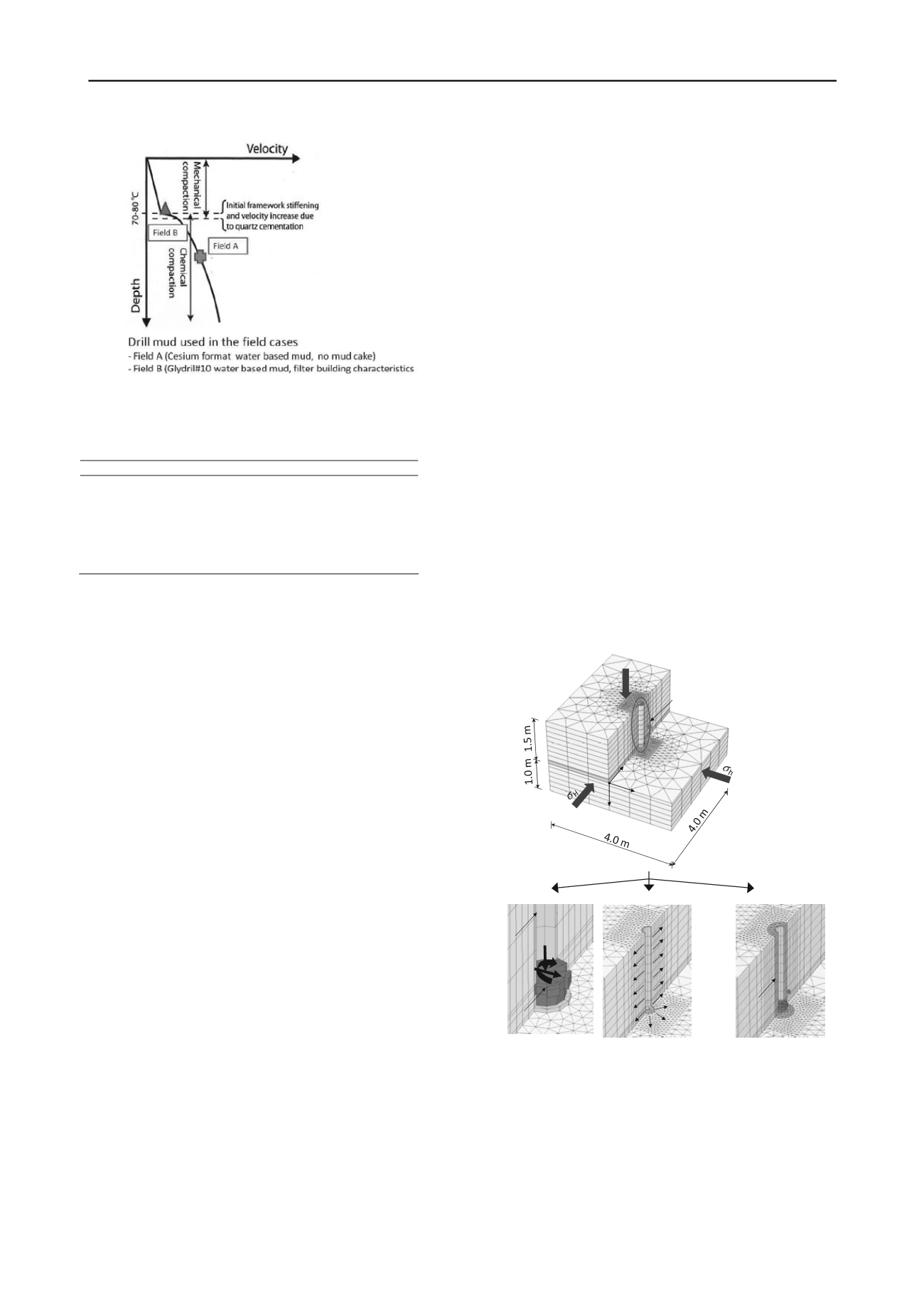

Figure 1. Field data used for study of formation damage. Depth of burial

varies between two fields A and B, leading to pronounce difference in

terms of quartz cementation. Also use of different muds leads to

different mud cakes at wellbore walls.

Table 1. Material properties at wellbore at Field A and B.

Parameters

Field A

Field B

Unit

Depth

~4100

~2400 mTVD

Porosity

16-25

27-32

%

Young modulus

5

GPa

Poisson’s ratio

0.15

0.27

-

Cohesion

8.7

3.2

MPa

Friction angle

33

29.1

degree

Tensile strength

3.2

1.2

MPa

formation during drilling and coring operations. In the first part,

an example of workflow will be outlined throughout the

numerical modelling performed at two macro (continuum) and

micro scales based on data from the two field cases: Field A and

B. Figure 1 illustrates the locations of Field A and B where the

Radial Diapole Profiling data is available. The material

properties at the two field cases are given in Table 1. They

basically differ from each other in term of burial depth, leading

to different degrees of cementation between grains.

The second part will present the FE-results calculated by

using the macro FE-model while the third part will discuss in

detail about the application of the 2D micro FE-model for

analysing and predicting tensile fracturing observed on a micro

level (grain scale) in the formation during drilling and coring

operations.

2 METHODOLOGY AND WORKFLOW

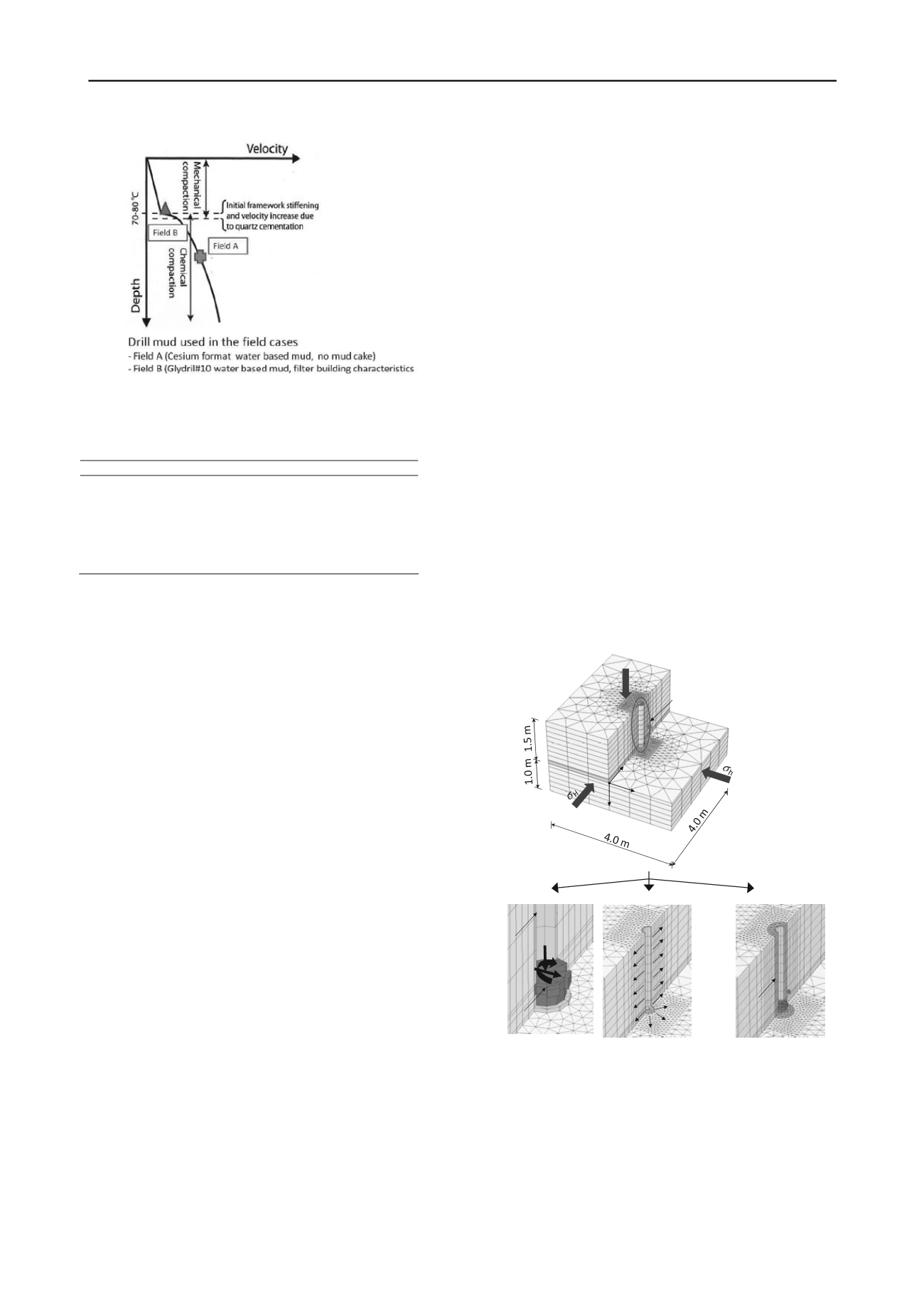

In the first stage a macro 3D FE-model was established for

calculation of continuum stress changes around wellbore, which

were mainly caused by lateral vibrations and torque from drill

bit, radial stress release and mud-fluid flowing into the

formation and temperature changes as illustrated in

Figure 2

.

Several assumptions have been made:

•

The rocks behave as a homogeneous material. Hence, its

mechanical behaviour can be described by using a

continuum mechanical approach;

•

The distances from the wellbore to the boundaries in the

two horizontal (x) and (z) and vertical (y) directions were

sufficiently large to avoid any effect of the outer boundaries

on the stress changes close to the wellbore;

•

The elements were modelled assuming an elastic

perfectly plastic, frictional-cohesive material that followed

the Mohr-Coulomb failure criterion after the onset of yield.

In addition to shear failure, the model also performs failure

in tension. The material parameters used in the Mohr-

Coulomb model are summarised in Table 1.

This FE-model was applied for the detailed study of the two

Field cases A and B presented in Figure 1. A transient pore

pressure analysis was performed in order to study the time

dependent dissipation of excess pore pressure due to the mud-

fluid flowing into the formation. In general, a total of five

numerical simulation steps need to be performed in order to

evaluate the stress changes in the rock surrounding the wellbore

during drilling and coring operations:

a. Initial stresses are first generated by applying the in-situ

stresses to the FE-model without the wellbore. The

considered stress states correspond to 2400 m “true vertical

depth” (TVD) and 4100 m TVD below mean sea level for

Field B and Field A, respectively;

b. The wellbore is then excavated under the hydraulic

support from the net mud pressure to simulate the drilling

stage;

c. In this step, forces at the drill bit are applied. All forces

from cutters, bit body and gauge pads are summed and

applied as resulting forces at the centre of the drill bit;

d. Then the mud-fluid infiltrates into the formation and

gives an applied increase of pore pressure around the

wellbore;

e. Finally, the reduction of the temperature is simulated by

reducing the volumetric strain.

From a parametric study the mud temperature was found to be

important with respect to generation of tensile fractures which

are the most plausible failure mechanism. Downhole

temperature logs measured at the drill bit were available, but

these did not cover the entire history of temperatures during the

various stages of drilling and circulations in the period between

drilling and logging of the actual intervals. Due to the large

impact of temperature on failure and the poorly documented

temperature history of the study intervals, an assumed constant

temperature change is applied one wellbore radius into the

formation in order to simulate the cooling of formation during

process of drilling. The stress situation one radius into the

formation was evaluated with respect to fracturing due to tensile

failure.

WOB

F

bit

From drill bit

Drill bit

Mud cake

TOB

From

temperature

T within 1

radius from

wellbore side

Frommud

v

Borehole

(r ×h : 0.108 × 1.5 m

infiltration of

mud-fluid

y

A

y

z

x

A

Figure 2. Full 3D FE modelling of different loads due to drill bit torque

and axial load, mud-flow into formation and temperature change within

one radius from wellbore wall.