1025

Technical Committee 105 /

Comité technique 105

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

1) Set-up the geometry of the walls and floor of the container

and the elements on the floor where the contact stresses

will be monitored and the details of the trapdoor as shown

on the left hand side Figure 1. The trapdoor is 150 mm

long and 150 mm wide and consists of three elements 50

mm long by 150 mm wide. The walls and floor of the

container are assumed to be rigid.

The normal and tangential stiffnesses between the floor

elements and the spherical particles are the same as those

of between the spherical elements. The friction coefficient

between the spherical particles and the floor elements is

0.5, which is the same as that between the particles.

2) Generate the spherical elements above the floor in the upper

part of the container to a depth of 150mm. Calculations

are repeated under gravity loading until the displacement

rates of the spheres approach zero and the bed has come

to equilibrium. Knowing the maximum and minimum

void ratios of Toyoura sand, the relative density of the

sand bed was estimated to be 86%.

3) To simulate the trapdoor tests, the trapdoor was lowered at a

constant displacement rate of 5mm/sec. The vertical

stresses on the trapdoor and the floor next to the trapdoor

were calculated.

For the gravity flow simulations, the trapdoor was

removed instantaneously and dynamic vertical stresses on

the floor next to the trapdoor were calculated.

3 RESULTS AND DISCUSSION

First, the experimental data is compared with the DEM analysis

data in the trapdoor tests and then the gravity flow simulation is

discussed.

3.1

Trapdoor tests

Figure 2 shows the variation of vertical stress,

p

, on the trapdoor

against the downward displacement,

d

t

, and on the floor

elements adjacent to the trapdoor. The depth of the sand layer

was 150 mm, equal to the width of the trapdoor; the initial

vertical pressure on the floor of the container was 2.38kN/m

2

.

The plots compare the experimental data obtained by Kikumoto

et al (2003) with the calculated DEM values. The centre of

elements A, B and C are respectively 150mm, 300mm and

450mm from the centre of the trapdoor. It is seen that the

vertical stress adjacent to the trapdoor is affected by the

trapdoor movement but further away the influence of the

movement is negligible. The vertical stress on the trapdoor

rapidly decreased at the onset of the downward movement, and

the experimental and DEM values corresponded well. The final

value when

d

t

= 2.0mm is 0.62kN/m

2

for the DEM results. On

the other hand, the vertical stress on element A increased

rapidly with the lowering of the trapdoor and then settles to a

constant value of 3.0kN/m

2

in the DEM. The initial rate of

increase for the vertical stress for element A in the DEM results

is different from that of the experimental data. This reason is not

clear, but it may be related to the difference in dilation rate

between Toyoura sand and spherical DEM elements.

The vertical stresses on floor elements B and C increased

slightly and there is good agreement between the experimental

data and the calculated DEM results.

Figure 3 shows the distribution of vertical stress laterally

from the centre of the trapdoor when

d

t

= 2.0mm. The vertical

stress on the trapdoor decreased and increased on the floor next

to the trapdoor. The DEM data show a sawtooth distribution not

seen in the experimental data.

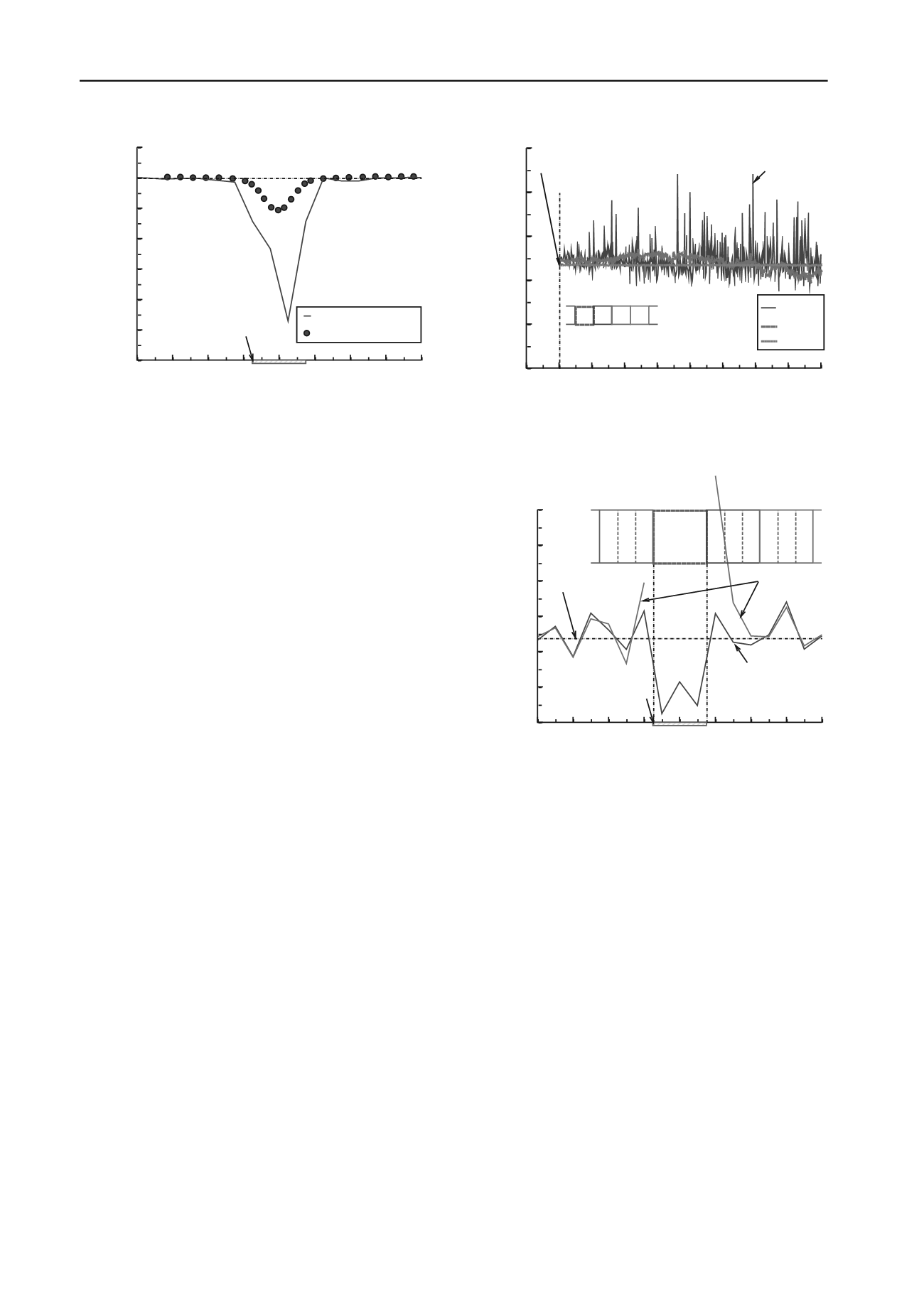

Figure 4 shows the surface settlement of the sand above the

centre of the trapdoor when

d

t

= 2.0mm at the depth of the sand

layer was 150 mm. The experimental data was measured by the

laser displacement scanner which accuracy was 1

m (Kikumoto

et al. 2003). It is, however, Figure 4 that reveals the most

significant shortcoming of the DEM modelling as the

experimental and calculated subsidence trough at the upper

surface of the sand are very different; the surface settlement in

-400 -300 -200 -100 0 100 200 300 400

0

1

2

3

4

5

6

Earth pressure,

p

(kN/m

2

)

Horizontal distance from the centre of trapdoor,

h

d

(mm)

DEM (trapdoor)

DEM

(gravity flow)

gravity flow

initial earth pressure

(=2.38kPa)

trapdoor

t

=0.3sec

Figure 4. Surface settlement of the sand above the centre of the

trapdoor when

d

t

= 2.0mm, layer thickness 150 mm.

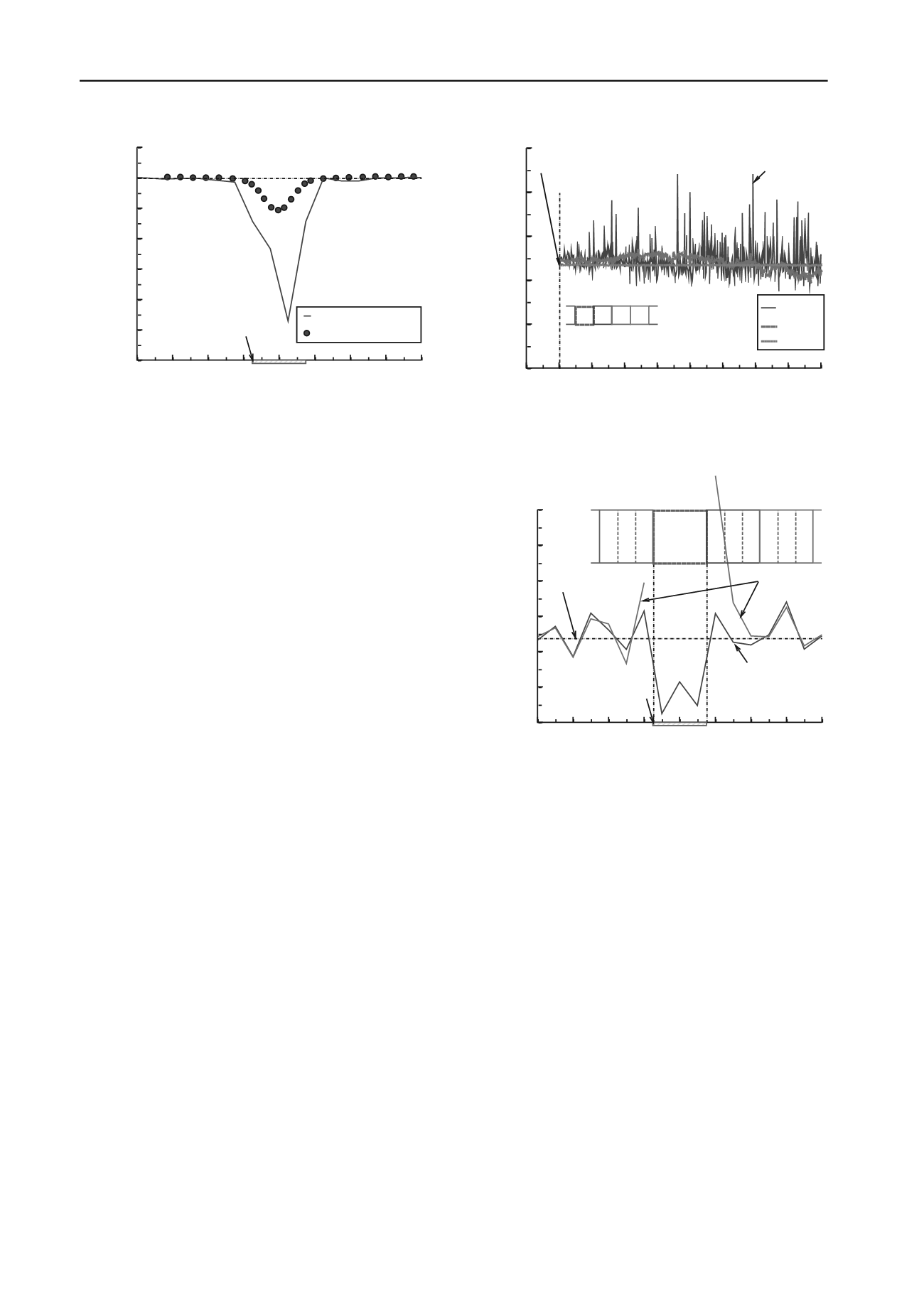

Figure 5. Vertical stress on the floor next to the trapdoor during

gravity flow.

Figure 6. Comparison of vertical stress distributions on the floor

next to the trapdoor during trapdoor lowering and during gravity

flow at the elapsed time of 0.3sec.

-0.05 0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40

0

1

2

3

4

5

Earth pressure,

p

(kN/m

2

)

Elapsed time after the trapdoor deleted,

t

(sec)

C (DEM)

B (DEM)

A (DEM)

gravity flow

A B C

initial earth pressure 2.38kPa

t

=0.3sec

-400 -300 -200 -100 0 100 200 300 400

3.0

2.5

2.0

1.5

1.0

0.5

0.0

-0.5

Surface settlement,

s

s

(mm)

Horizontal distance from the centre of trapdoor,

h

d

(mm)

Kikumoto et al. 2003

DEM

trapdoor