1033

Technical Committee 105 /

Comité technique 105

in the work by Santamarina (2001). This phenomenon was also

reported by Yang and Gu (2012) in their experimental study.

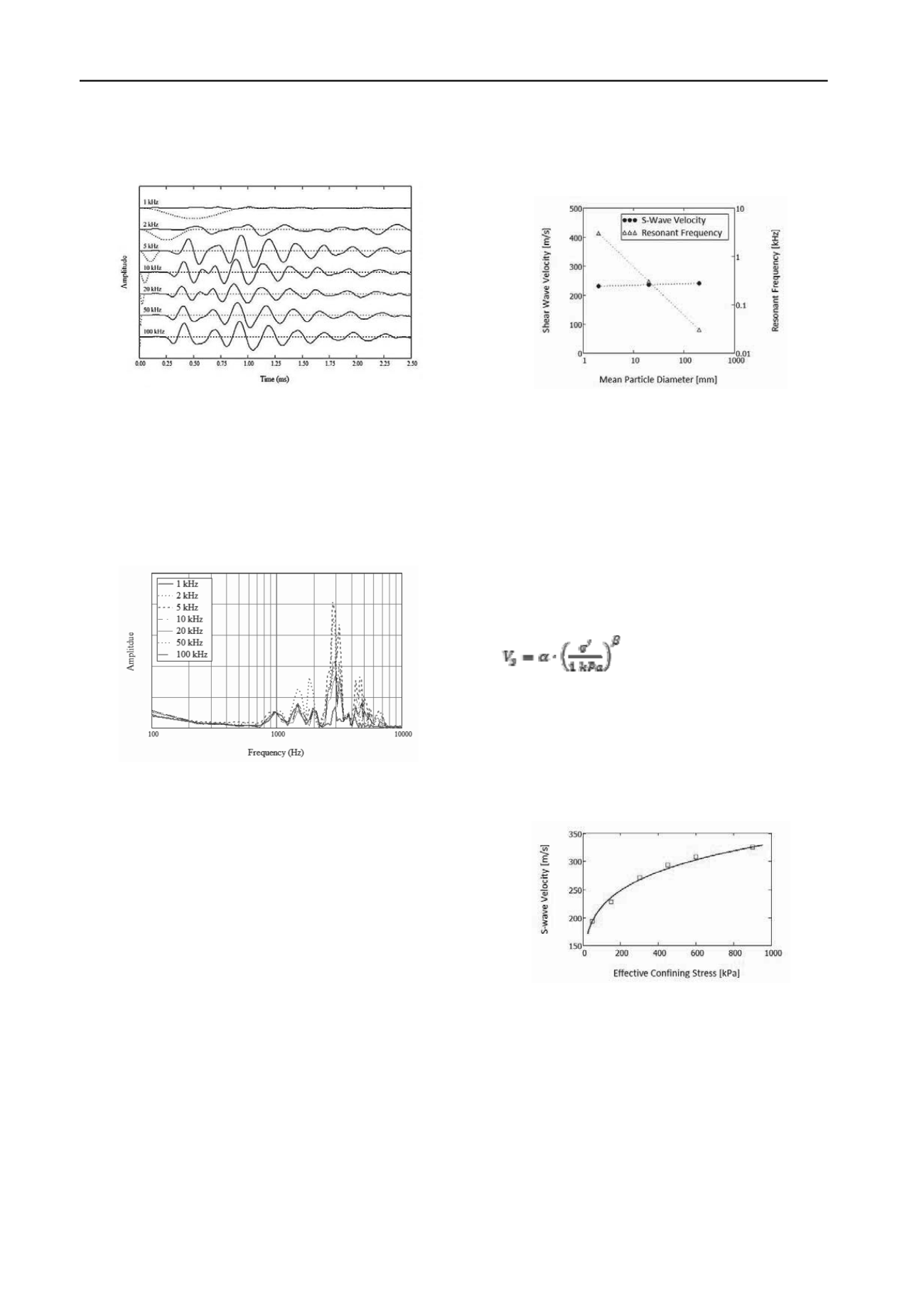

Figure 3. Response of a receiver in the time domain, excited by a sine

pulse with different frequencies (D

50

= 2.0 mm; e = 0.63; σ'

3

= 150 kPa.

Note: for clarity, the scale of the magnitude for the source signal and the

receiving signals are different)

Because the materials with internal spatial scales are

inherently dispersive (Santamarina 2001), wave propagation

velocity varies with frequency in granular soils. There are

experimental studies (Blewett et al. 2000; Styler and Howie

2012) showing frequency-dependent S-wave velocity responses.

In the 2D DEM simulation by O’Donovan et al. (2012), the S-

wave velocity increases linearly with the transmitted frequency.

Figure 4. Response of receiver in frequency domain, excited by sine

pulse with different frequencies (D

50

= 2.0 mm; e = 0.63;

σ'

3

= 150 kPa)

.

Figure 3 shows that the variation of the first arrival of the S-

wave can be observed, though it is not obvious. The S-wave

velocity increases slightly (from 220 m/s to 231 m/s) when the

transmitted frequency increases from 1 kHz to 5 kHz. This is

attributed to the viscous damping effect at the inter-particle

contacts (O’Donovan et al. 2012). When the transmitted

frequency is higher than the resonant frequency, the variation of

S-wave velocity becomes even less appreciable (a consequence

explained by the aforementioned low-pass filter effect).

4 PARTICLE SIZE AND CONFINING STRESS EFFECTS

The effect of particle size on S-wave velocity has been widely

studied by using bender element tests. A recent work by Yang

and Gu (2012) found controversial results by comparing many

previous researches. DEM simulation allows for the study of

particle size effect with a much larger size range than physical

test does. Knowing the particle size effects on wave propagation

problem is also important for DEM simulation to determine

whether the mass-scaling (O'Sullivan, 2011) is applicable.

Three mean particle sizes were considered (2 mm, 20 mm, 200

mm). Since wave propagation involves high frequency effects,

different responses are expected from models with different

particle sizes. Figure 5 shows the effects of particle size on S-

wave velocity and resonant frequency. There was little change

in S-wave velocity over three orders of magnitude in particle

size. This agrees with Yang and Gu (2012), who found that S-

wave is effectively size independent. Regarding the resonant

frequency of model, a linearly decreasing trend with the particle

size was observed.

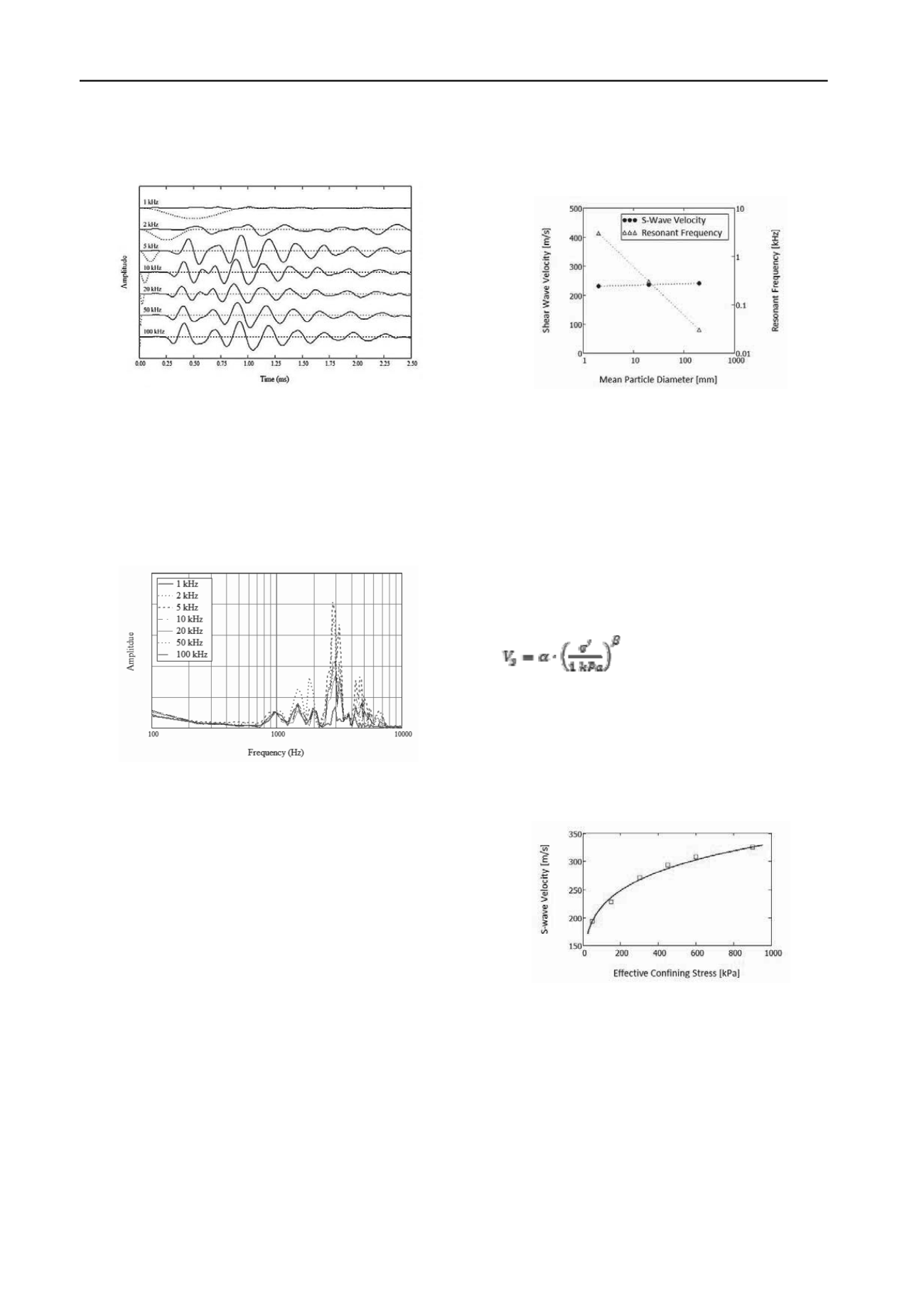

Figure 5. Effects of particle size on S-wave velocity and resonant

frequency (D

50

= 2 mm, 20 mm, 200 mm; e = 0.62–0.63; σ'

3

= 150 kPa)

These results indicate that mass-scaling (e.g. by manipulating

the particle size; Evans and Frost 2007, Jacobson et al. 2007,

Belheine et el. 2010) can be applied to reduce computing time

in DEM simulations of S-wave propagation. The excitation

frequency should be carefully selected near the resonant

frequency (a function of the particle size) to obtain strong

frequency response in the model.

Stress state affects interparticle stiffness (Santamarina 2001)

and, perhaps more significantly, contact quality (Evans et al.

2011) and thus, wave propagation speed. Many empirical

relationships between S-wave velocity and effective confining

stress have been proposed (Hardin and Richart 1963) for sands.

One general form is as follows:

(1)

where

α

and

β

are fitting parameters and

σ'

is the effective

confining stress in kPa.

In this study, the S-wave velocities of a DEM specimen with

D

50

= 2.0 mm were determined under confining stresses ranging

from 50 to 900 kPa. The simulation results present a similar

trend as observed in the lab as shown in Figure 6. The fitting

parameters

α

and

β

were found to be 95.5 and 0.18 respectively,

which fall into the range of typical values for sand and OC clay

(Fernandez 2000)

Figure 6. Effects of confining stress on S-wave velocity (D

50

= 2.0 mm;

e = 0.62-0.63)

5 MICROMECHANICAL OBSERVATIONS

In laboratory tests, it is not possible to directly observe complex

wave motions within the specimen. DEM simulations allow for

micromechanical predictions of material response, which can

help to provide a better understand of the complexity of wave

propagation mechanisms in granular materials. Observations of

the particle velocity vectors are briefly considered below.

Figure 7 shows particle velocity vectors on three specific

cutting planes of a DEM specimen 10 ms after excitation. The

cutting plane on the left goes through the central axis of the

specimen with its normal parallel to Y-axis. The cutting plane

1-1 and the cutting plane 2-2 are at the height of two receivers

respectively with their normal parallel to Z-axis. The particle