1028

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

appropriate the bentonite was stretched with rounded inert

quartz grains (washed Perth sand, d

50

= 0.24 mm, Cook

Industrial Minerals, Australia).

The pore water of the reconstituted samples was prepared

with a 0.01 mol/L CaCl

2

solution as standardised groundwater

equivalent.

Guanidinium solutions were prepared from analytical grade

guanidinium hydrochloride salt (C(NH

2

)

3

Cl, ≥99%, Fluka

Analytical, Switzerland) and demineralised water.

2.2

Investigations on particle scale

Homo-ionic bentonites were produced by saturation of Calcigel-

clay with 1.0 mol/L calcium and guanidinium solutions,

respectively. Images of the particles and aggregates were taken

with a scanning electron microscope. The grain size distribution

of the suspended material was measured with a Laser scattering

analyser (Partica LA-950, Horiba, Germany).

After saturation, the modified soils were washed in

suspension with demineralised water to remove excess ions and

to avoid salt precipitation in the inter-particle pore space.

Compacted samples were reconstituted from the washed

material at water contents slightly above to their liquid limit.

Mercury intrusion porosimetry (MIP, PASCAL 240/440,

Porotec, Germany) on dry samples was used to quantify the

alterations of the pores system due to guanidine treatment.

Crack-free pieces of the slowly dried clays were subjected to

vacuum evacuation for 2 h prior to mercury intrusion.

2.3

Macroscopic tests

The primary and intended soil improvement of chemically

enhanced drainage is the increase in hydraulic conductivity.

This increase was measured based on the evaluation of time

settlement curves on bentonite samples. For this purpose,

compacted samples of unmodified bentonite were reconstituted

and mounted into a standard oedometer cell. The chemical agent

was then delivered to the soil in the pore water by diffusion

from the top and bottom filter plates. Subsequent loading up to

800 kPa allowed deriving hydraulic conductivities at different

void ratios. Untreated samples served as reference for

comparison.

Oedometric tests on compacted mixtures of bentonite (40 %)

and quartz sand (60 %) were carried out to assess both the

increase in permeability and the effects on stiffness due to the

chemical treatment. Samples were reconstituted with different

chemical composition of the pore water - either artificial

groundwater or guanidinium solutions - and subsequently tested

according to the procedure given in ASTM D2435-04.

The same mixtures were used in constant head permeameter

tests, were the permeability was measured on both modified and

unmodified soil. Additionally, the temporal evolution of the

permeability during flow-through treatment with guanidinium

solutions was recorded for a sample with initially unmodified

soil.

Since chemically enhanced drainage is planned to be applied

in the context of stabilisation measures, the effects of the

chemical modification on the strength parameters of the soil

should not be neglected. Therefore, we assessed the influence

on the residual shear resistance of pure bentonite samples with a

ring shear apparatus. The samples were directly reconstituted

from homo-ionic calcium and guanidinium bentonites, as the

device used in this study did not allow for chemical

modification of the soil within the sample cell.

3 RESULTS AND DISCUSSION

3.1

Modification of particles and pores

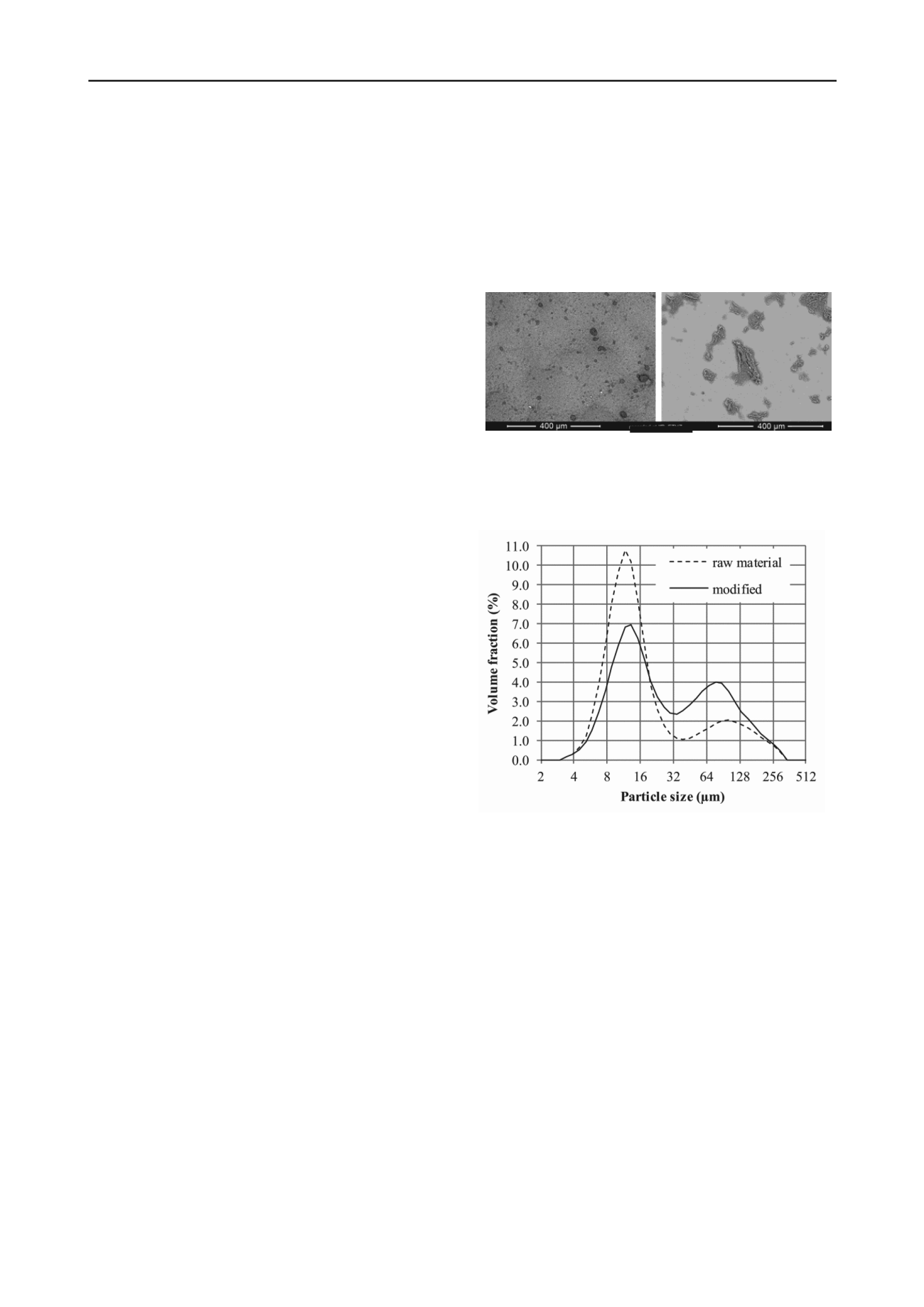

During sample preparation of modified bentonites, a granular,

non-plastic behaviour was observed. Images taken with a

scanning electron microscope (Figure 1) revealed that in

suspension the clay fraction aggregated upon addition of

guanidinium.

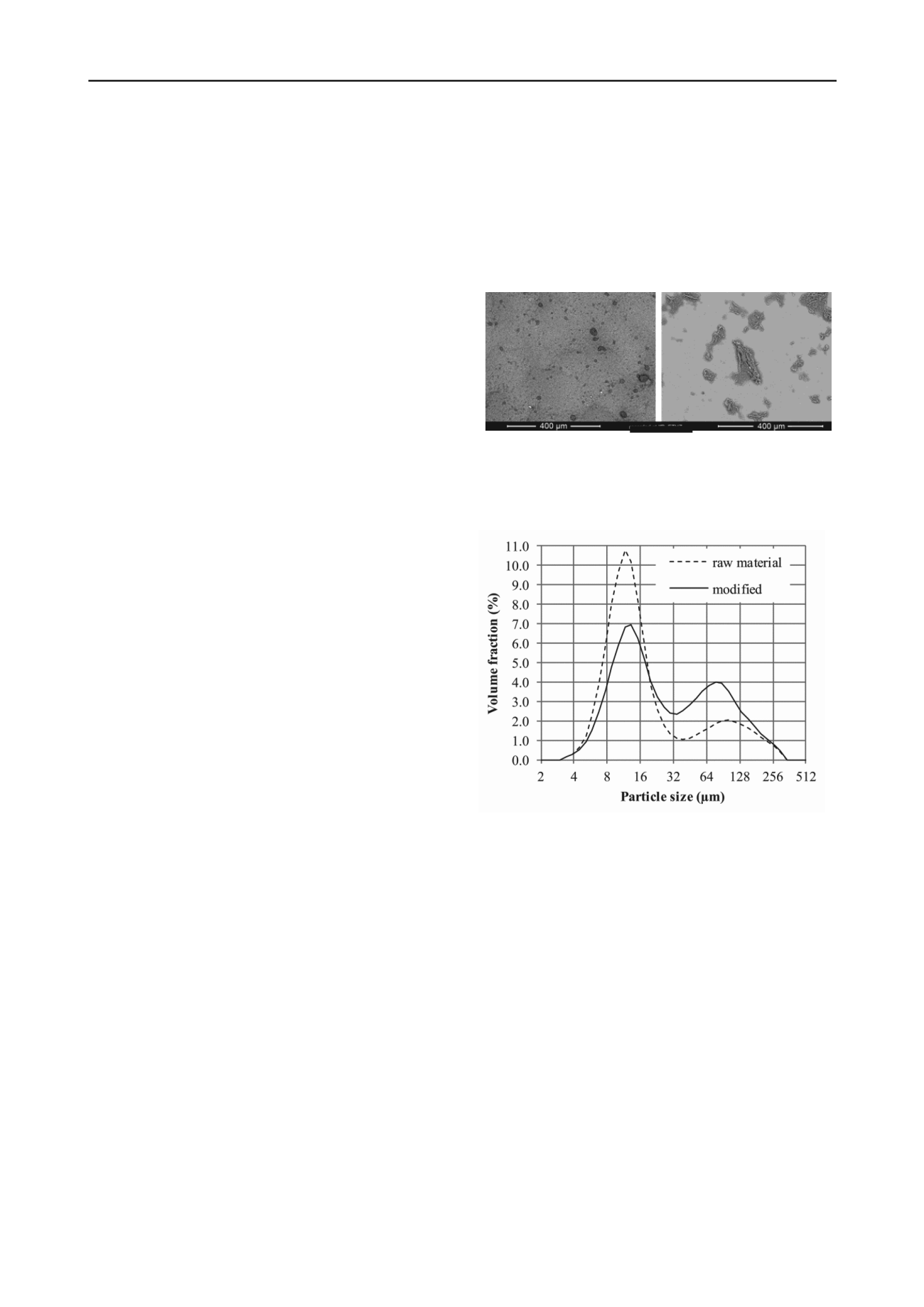

The measurement of the particle size distribution supported

this observation. Both calcium and guanidinium bentonites

feature a bimodal distribution. However, figure 2 shows that the

total volume fraction of the larger mode – containing the

aggregates – is almost doubled for the guanidinium samples

(42.4 %) compared to the calcium clay (22.4 %).

Figure 1. SEM-images of bentonite grains after washing in suspension

with demineralised water. The calcium form remains finely dispersed

(left), whereas the exposure to guanidinium ions (right) leads to the

formation aggregates.

Figure 2. Bimodal particle size distribution measured with laser

diffraction. The volume fraction of the larger mode (aggregates) is

significantly increased by the chemical modification.

Compacted samples were analysed with MIP in order to

examine whether these aggregates were capable of maintaining

an open pore structure. Considerable changes in the pore system

were detected. Even though the unmodified soil was prepared at

a higher water content (w

L,Ca

= 102%) the modified bentonite

(w

L,Gnd

= 64%) features a larger accessible pore volume

(Figure 3). The largest contribution to the additional pore

volume stems from pores with average radii of 2 µm. The total

pore volume of these larger pores had increased, the volume in

the smaller pore fraction (radius < 0.1 µm) however was slightly

reduced compared to the reference material.