1030

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

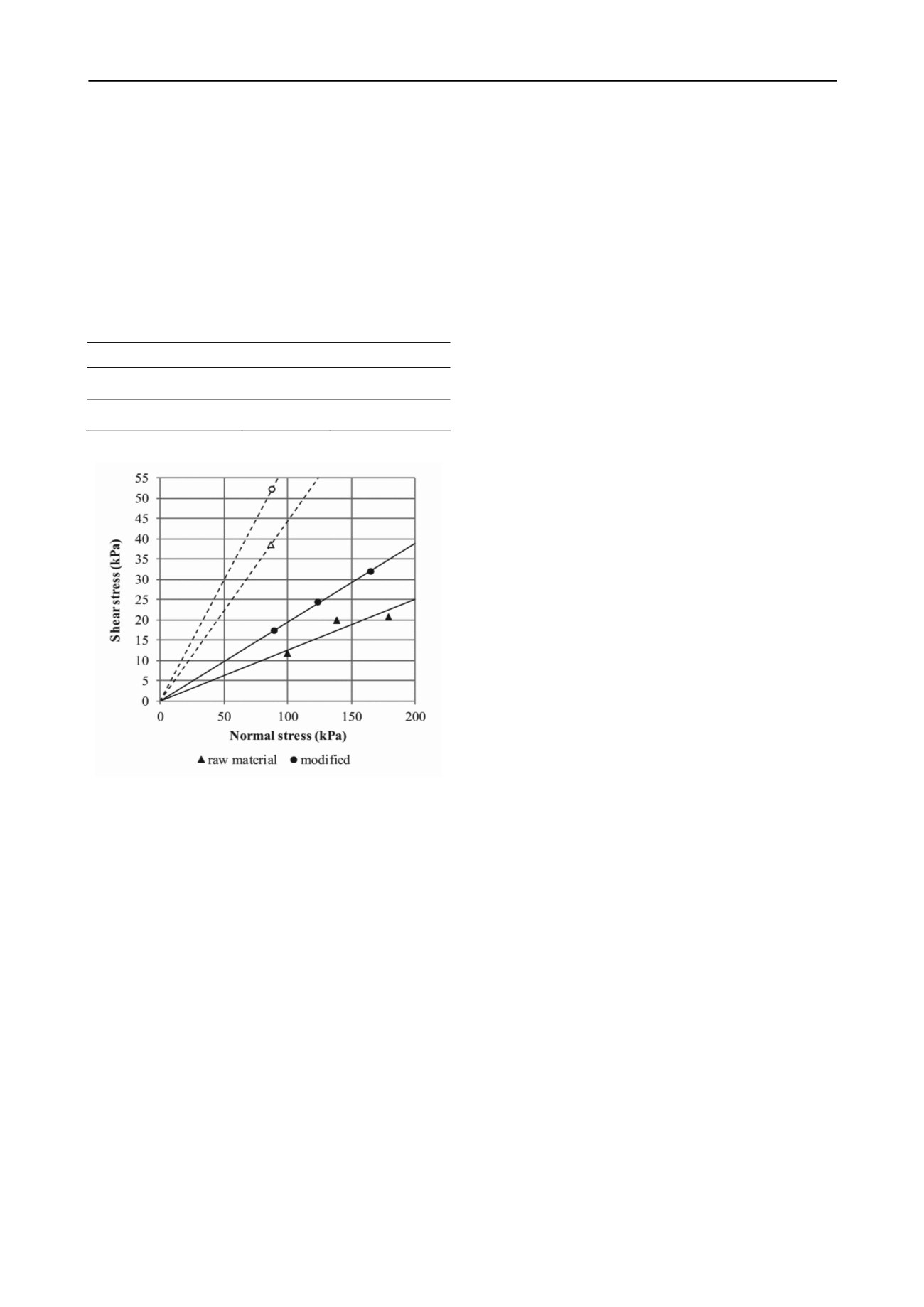

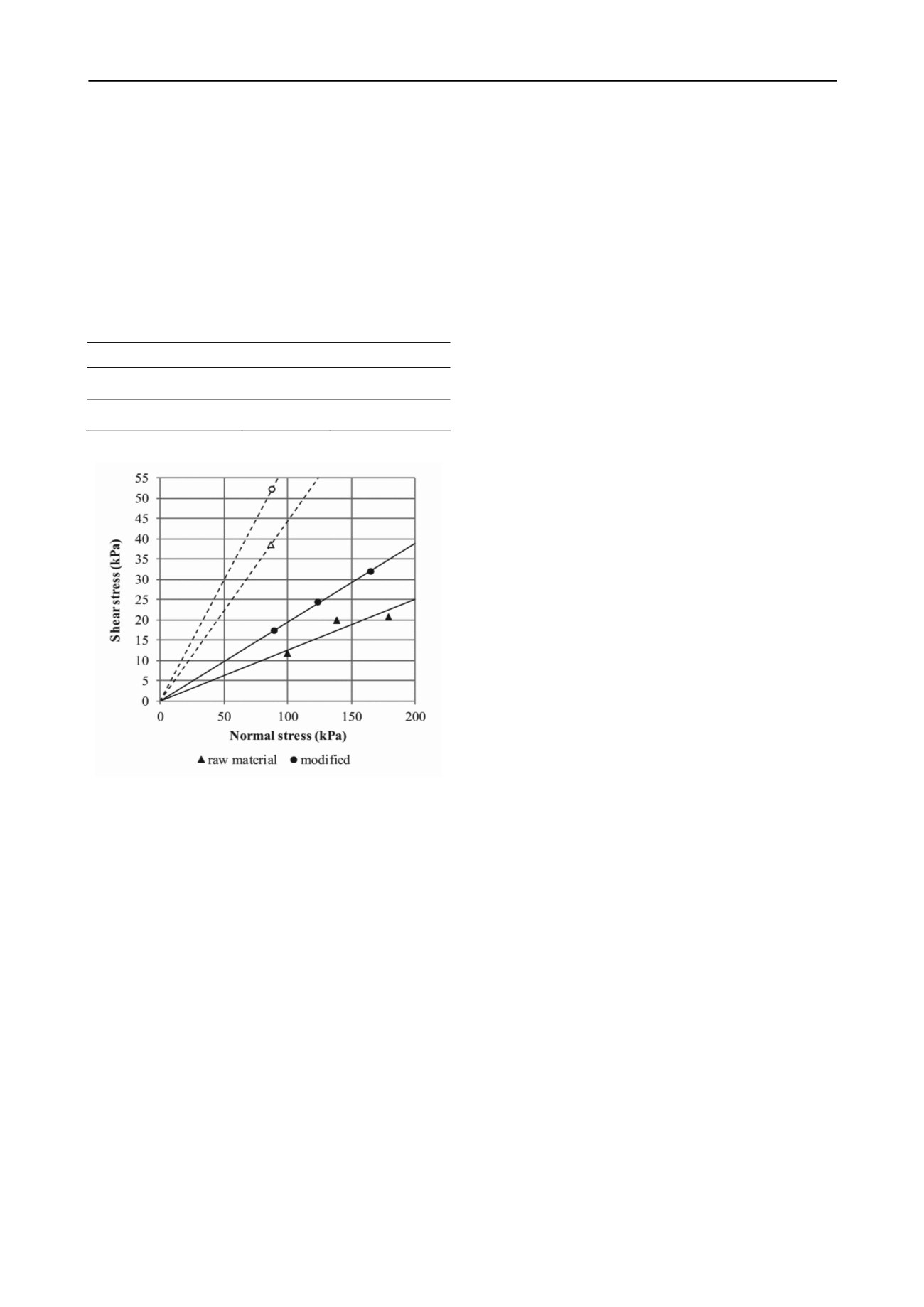

shear resistance was measured by a multi-stage procedure with

a constant shear velocity of 0.2 mm/min and three different load

steps for each sample. Figure 7 shows the residual shear stress

after 30 to 40 mm of displacement. Moreover, the first load step

was used to measure one value for the peak shear resistance. By

assuming zero cohesion this peak value was used to derive the

peak friction angle for each material. Table 2 summarises the

friction angles obtained from this data set. It shows that both

peak and residual resistance are increased after chemical

treatment.

Table 2. Strength parameters of bentonite samples. For all values a

rictional material with zero cohesion was assumed.

f

Raw Material

Modified Material

Peak friction angle

24°

31°

Residual friction angle

7°

11°

Figure 7. Results of multi stage ring shear tests on bentonite samples.

The empty symbols represent peak shear resistance of the initial failure

during the first load step loading. Residual state (full symbols) was

reached after 30 to 40 mm of displacement in each load step.

4 CONCLUSIONS

Based on the experimental work on different scales the

following conclusions could be drawn:

The molecular change of the clay minerals on the level of the

surface chemistry results on the particle scale in an aggregation

of small clay minerals to larger and stable particles. The

aggregated, non-swelling particles provide an open pores

system with pores of about 2 µm. Upon wetting these pores are

no longer filled with an expanding clay phase but kept open.

The pore water is not bound as immobile interlayer water and

remains available for circulation.

The compression tests have shown that the new structure is

stable also under stresses up to 800 kPa for both pure bentonites

and quartz/bentonite mixtures. Despite these drastic changes on

the microstructural level, the stiffness is not significantly

affected by chemical treatment. The material strength is

positively influenced by the chemical treatment as both peak

shear resistance and residual shear resistance for the modified

bentonite is higher compared to the raw material. A negative

influence on these mechanical properties can therefore be

excluded.

In summary, the findings are positive indicators for further

development of the technique towards purposely creating zones

of higher permeability in-situ as part of a drainage system in

creeping landslides.

5 ACKNOWLEDGEMENTS

The authors would like to thank Dr. M. Plötze of the ClayLab at

ETH Zurich for his help during chemical laboratory testing.

This work has been supported by grant Nr. 200021-137689

from the Swiss National Science Foundation, Switzerland.

6 REFERENCES

ASTM Standard D 2435, 2004.

One-Dimensional Consolidation

Properties of Soils Using Incremental Loading

, ASTM

International, West Conshohocken, USA.

F. Fernandez, R.M. Quigley, 1985. Hydraulic conductivity of natural

clays permeated with simple liquid hydrocarbons.

Can. Geotech. J.

,

22(2), 205-214.

G. Lagaly, M. Ogawa, I. Dékány, 2006. Clay Mineral Organic

Interactions. In: F. Bergaya, B.K.G. Theng, G. Lagaly, (eds.)

Handbook of Clay Science

, Elsevier, 309-377.

F.T. Madsen, J.K. Mitchell, 1989. Chemical effects on clay hydraulic

conductivity and their determination.

Mitteilungen des IGBM

, ETH

Zürich, 135, 67.

M. Plötze, G. Kahr, 2008. Diagnostic intercalation in clay minerals –

use of Guanidine carbonate.

Proc. of the 4th MECC, Mineralogia

,

33, 132.