1029

Technical Committee 105 /

Comité technique 105

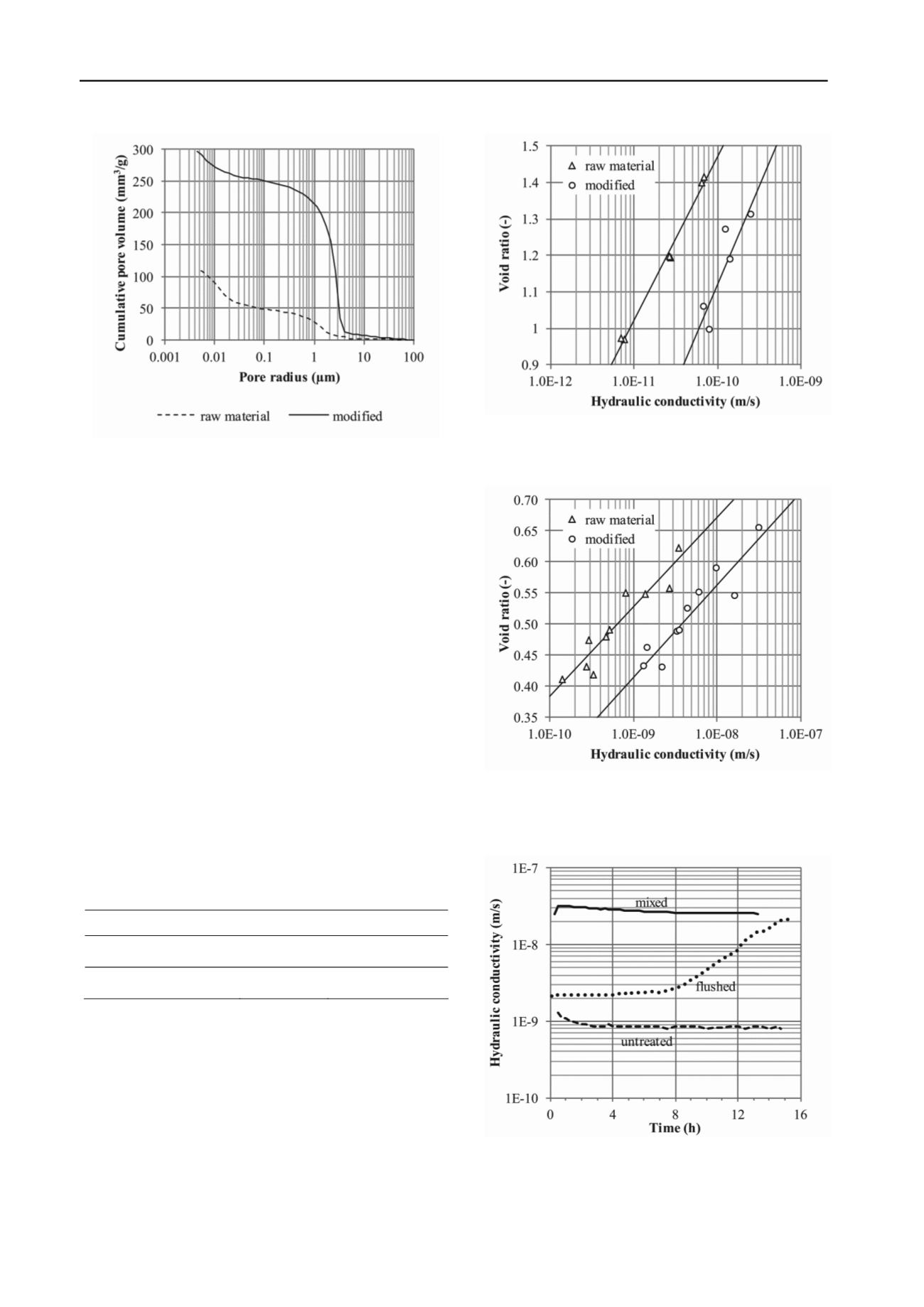

Figure 3. Cumulative pore size distribution of two bentonite samples

measured with mercury intrusion porosimetry. The modified material

features a much larger pore volume fraction in pores with radii of about

2 µm.

3.2

Geotechnical parameters

The tests on pure Calcigel samples, where the chemical was

delivered without mixing but diffusively, showed a constantly

improved hydraulic conductivity even with this gentle treatment

method. The evaluation of the time-settlement curves based on

the theory for one dimensional consolidation showed that –

although the absolute permeability decreased with increasing

compaction – the relative improvement compared to the raw

material was preserved and ranging in the order of one

magnitude (Figure 4). The aggregated clay minerals are

apparently able to keep the newly created flow paths open also

without the presence of a rigid sand skeleton.

Oedometer tests on a triplicates series of the quartz/bentonite

mixtures were additionally analysed with respect to changes in

stiffness. The difference between unmodified and natural soil

was small and in the order of the standard deviation for both

initial loading and unloading/reloading (Table 1). The

evaluation of the time-settlement curve again provided

hydraulic conductivities at different stress levels. Figure 5

clearly shows, that despite vertical stresses of up to 800 kPa

(corresponding to the smallest void ratios), the increased

permeability is maintained during compaction.

Table 1. Stiffness parameters averaged over three samples and three

oad steps each. Standard deviation is given in parenthesis.

l

Raw Material

Modified Material

Compression index Cc

0.38 (0.04)

0.35 (0.02)

Swelling index Cs

0.09 (0.03)

0.11 (0.03)

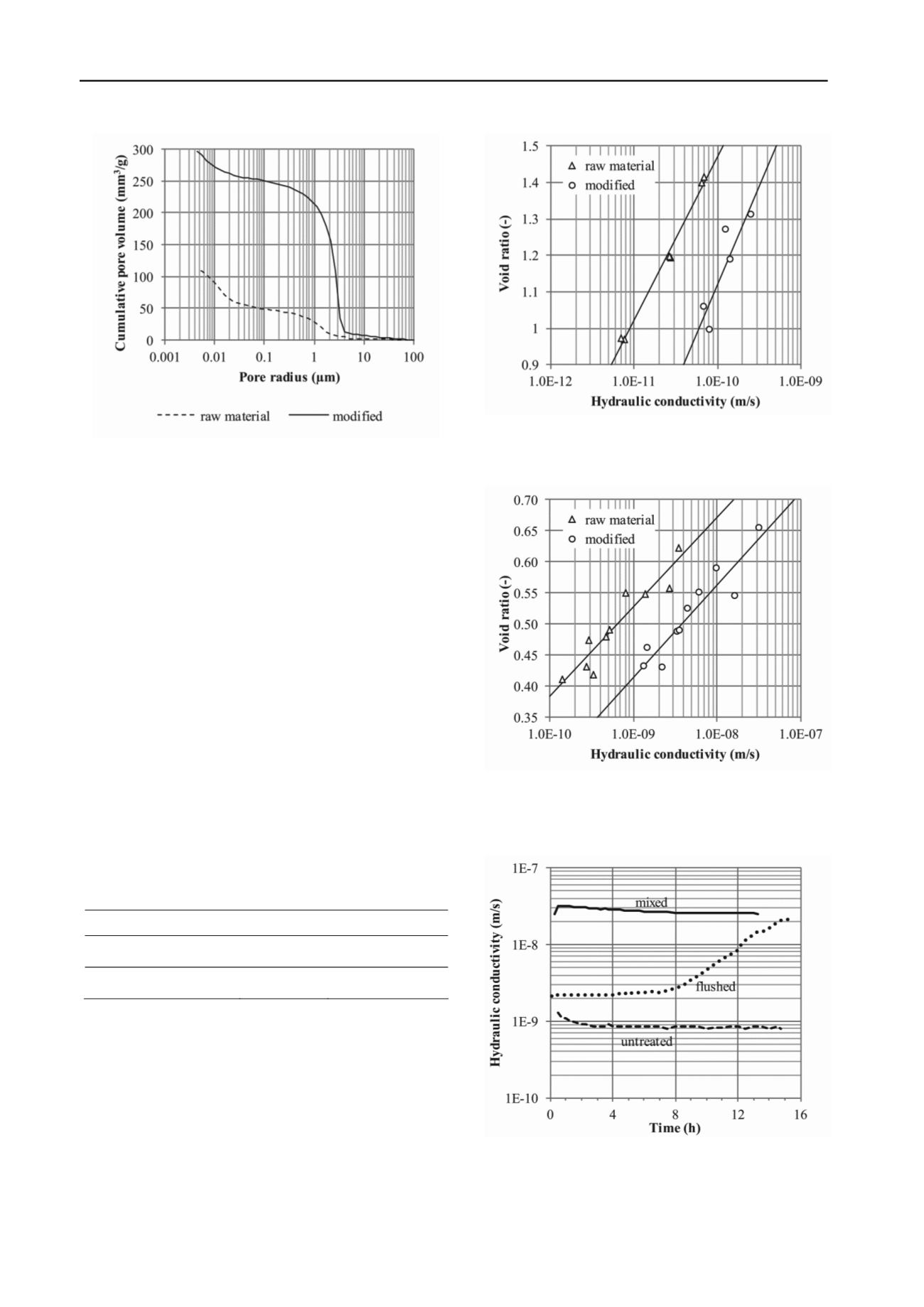

By means of permeameter tests the magnitude of possible

improvement under flow-through conditions was determined.

By mixing soils with guanidinium solutions an increase of the

permeability by the factor 30 was achieved (Figure 6). Even

when unmodified samples were simply permeated with

guanidinium solutions – instead of water – the average

hydraulic conductivity increased by one order of magnitude. In

potential field application this method of treatment could

facilitate the delivery of the chemical in-situ without mechanical

disturbance.

Figure 4. Decrease of hydraulic conductivity during sample compaction

(including log-linear regression) of bentonite samples. The relative

improvement is not deteriorated during compaction.

Figure 5. Decrease of hydraulic conductivity during sample compaction

(including log-linear regression) of quartz-bentonite mixtures. For

identical void ratio the modified soil is constantly about one order of

magnitude more permeable.

Figure 6. Evolution of hydraulic conductivity during flow-through

treatment (dotted line) with guanidinium solution. For comparison the

data for raw material (dashed line) and reconstituted modified soil

samples (full line) permeated with water are plotted as well.

The effects of the chemical modification on strength

parameters are presented based on ring shear tests. The residual