1017

Technical Committee 105 /

Comité technique 105

where

p

a

is standard atmospheric pressure (i.e., 0.1 MPa);

w

is

the water density at 4C;

T

0

is the reference temperture (1C is

used herein).

The tangential contact stiffness

K

s

then relates to

K

n

based on

PFC2D Guidelines (Itasca, 2004) by

K

s

= 2/3

K

n

.

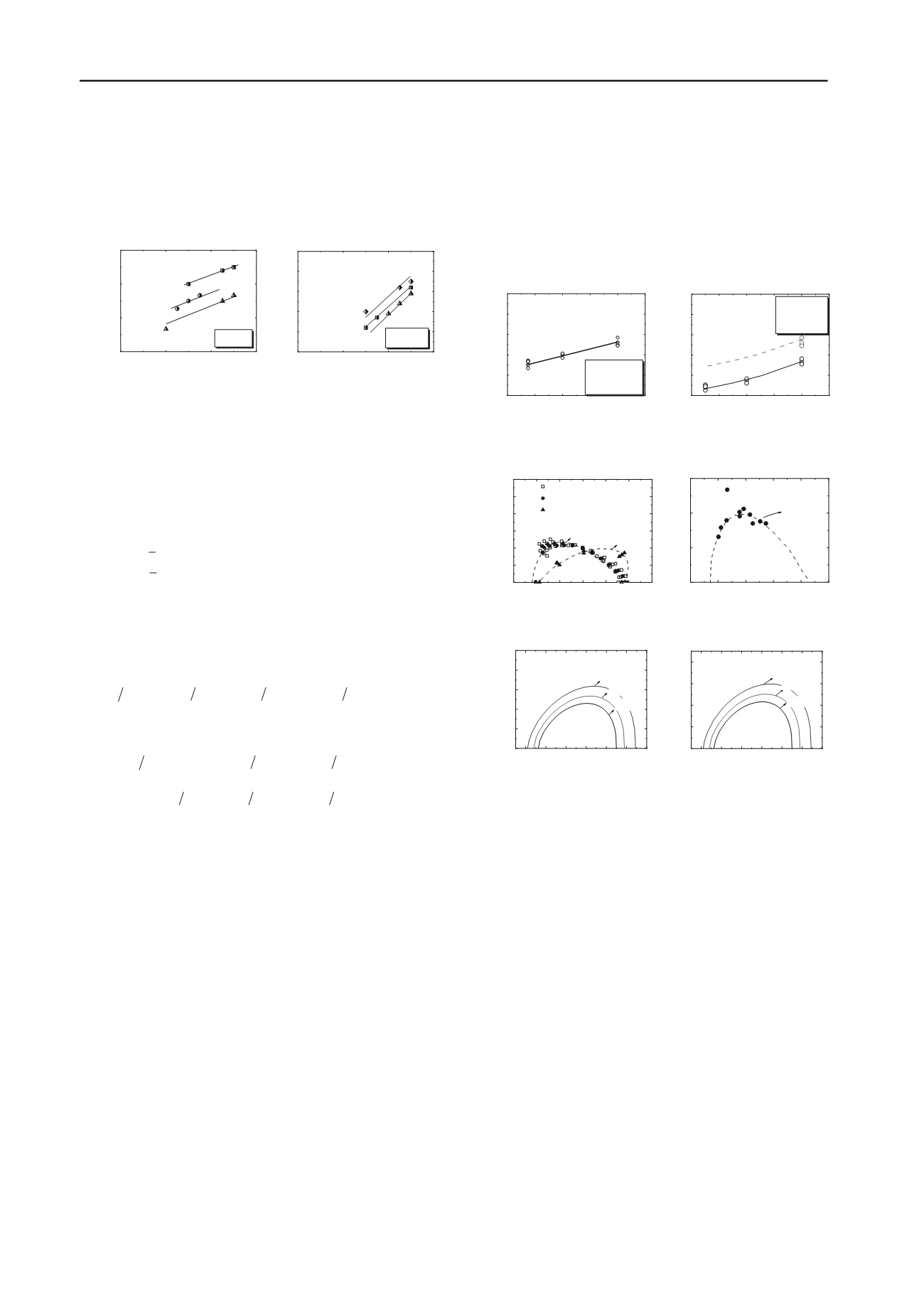

0.72

0.76

0.80

0.84

1.8

2.1

2.4

2.7

1.5MPa

4MPa

Elastic modulus

(

10

8

Pa

)

Density

g/cm

3

p

c

=8MPa

T= -30

0

C

(a)

0.72

0.76

0.80

0.84

2.2

2.3

2.4

2.5

2.6

2.7

5

0

C

-10

0

C

Elastic modulus

(

10

8

Pa

)

Density

(

g/cm

3

)

p

0

= 8MPa

T=-30

0

C

(b)

Figure 4. Elastic modulus of pure MH measured (a) at a given

temperature but varied confining pressure; and (b) at a given confining

pressure but varied temperatures (data from Hyodo et al. 2005)

2.4

Bond tension/compression strength

The bond tension and compression strength (i.e.,

R

t

and

R

c

in

Eqs. (4) and (5)) can be computed from the tension/compression

strength,

q

max

,

t

and

q

max,c

, of pure MH specimen subjected to a

given confining pressure

p

c

, i.e.,

max,

t

R Rq

t

(9a)

max,

c

R Rq

c

(9b)

As partially shown in Fig. 5, the peak deviator stress

q

max,c

obtained from the compression triaxial test on pure MH

specimens is a function of

T

,

p

c

and

(Hyodo et al. 2005). The

regression analysis of these data yields another empirical

formula:

max,

0

0.81

2.08

184.16

134.65

c a

c a

w

q p

p p

T T

(10a)

Eq. (9) is assumed to hold for tension triaxial test as well,

leading to the following:

max,

0

0.81 2.08

184.16

134.65

t

a

w

q p

p

T T

(10b)

where

0

0.55

1.15

100.09

74.39

c a

w

p

p p

T T

(11)

2.5

Fitting parameters

As already demonstrated in Fig. 2, the shape of the bond

strength envelope is controlled by the cementation materials,

resulting in different values of fitting parameters used in Eqs. (4)

and (5). Direct calibration of those parameters are rather

difficult for hydrate bonds. We assume that bond strengths are

dominated by the strength properties of cementation materials.

Fig. 6(a) shows the yielding curves of different materials. The

yielding curve is left skewed for cement-based materials and

right skewed for epoxy. Unfortunately, we are not able to

present the yielding curve for MH due to insufficiency of test

data available. As an ice-like material, MH was found similar to

ice in some physical properties (Solan et al. 1998; Dvorkin et al.

2000) and mechanical properties (Nabeshima et al. 2003; Choi

et al. 2009). Instead of MH, the yielding curve of ice is plotted

in Fig. 6(b) for comparison, which displays left skewed. We

concluded that the MH bonds produce a bond strength envelope

similar to cement bonds. The fitting parameters calibrated using

cement-bonded grains are used for MH-bonded grains. Eq. (5)

is re-written as:

0.38

1.16 0.498 (

) [(

) / (

)]

sb

n

t

c

n

n

t

R

F R R F F

0.38

R

R

(12a)

1.13 0.96 (

) [(

) / (

)]

rb

n

t

c

n

n

t

R

F R R F F

(12b)

Suppose a MHBS sample collected at 800 m below the sea

level (giving a pore water pressure of 8 MPa applied on MH

bonds in the sample) at 5C. The gradation curve of the soil

grains is assumed to be Fig. 3(b) and the initial void ratio of the

sample is 0.21. For a given

S

Hb

, the parameter

is determined

from the chart presented in Fig. 3(a).

R

t

and

R

c

computed from

Eqs. (9) to (11) are then substituted into Eq. (12) to obtain the

bond strength envelope. Fig. 7 illustrates a series of strength

envelopes at different levels of hydrate saturation. As expected,

the envelope expands omothetically with

S

Hb

.

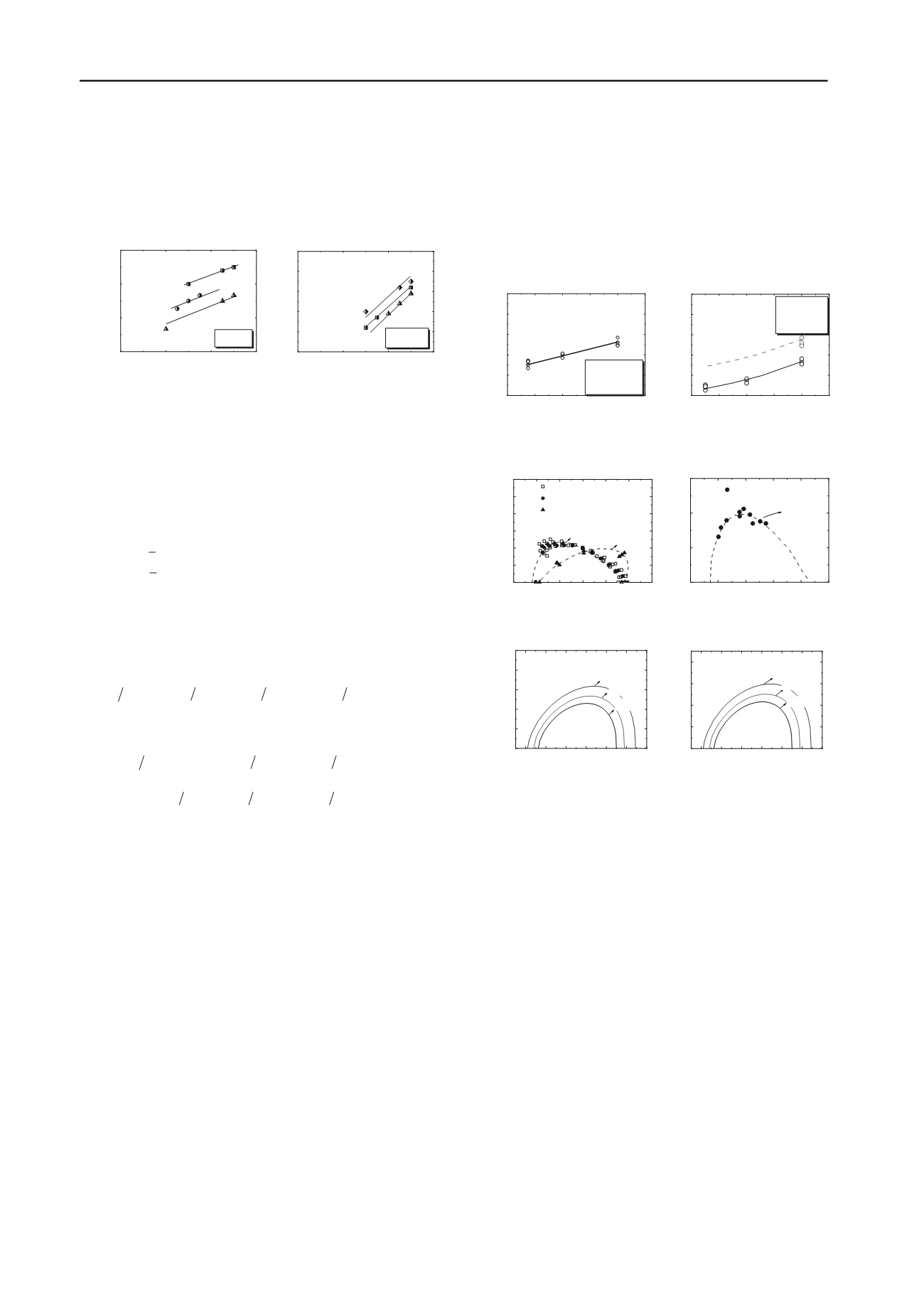

0 2

4

6 8 10

0

5

10

15

20

25

q

max

(MPa)

Comfining pressure

p

0

(MPa)

T

= -30

℃

= 0.8g/cm

3

(a)

10 0 -10 -20 -30 -40

0

5

10

15

20

25

High purity

Low purity

q

max

(MPa)

Temperature

(

℃

)

p

0

= 8MPa

= 0.8g/cm

3

(b)

Figure 5. The maximum deviator stress of pure MH measured (a) at a

given temperature but varied confining pressure; and (b) at a given

confining pressure but varied temperatures (data from Hyodo et al. 2005)

-1.5 -1.0 -0.5 0.0 0.5 1.0 1.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

Cement-based

Epoxy resin

Hussein & Marzouk 2000

Kupfer et al., 1967

Ellyin et al., 2005

3

/

3max

(

1

-

3

)/

3max

(a)

-0.3 0.0 0.3 0.6 0.9 1.2

0.00

0.05

0.10

0.15

Nadreau & Michel 1986

3

/

3max

(

1

-

3

)/

3max

ice

(b)

Figure 6. Yielding curves obtained from experiments for: (a) cement-

based materials and epoxy resin; and (2) ice

-20 -10 0 10 20 30 40

0

5

10

15

20

25

15%

24%

S

Hb

=41%

R

sb

(

kN)

Normal force

F

n

(kN)

-20 -10 0 10 20 30 40

0

10

20

30

40

15%

24%

S

Hb

=41%

R

rb

(

N

·

m)

Normal force

F

(a)

(b)

n

(kN)

Figure 7. Bond strength envelopes at different hydrate saturation: (a)

relationship between

R

sb

and

F

n

; and (b) relationship between

R

rb

and

F

n

3 DEM SIMULATION OF BIAXIAL TESTS ON MHBS

The proposed model for MHBS was implemented into the

commercial code PFC2D for simulating the biaxial compression

test on a MHBS specimen. For inter-particle contacts with

broken bonds or without bonds,

= 0.5,

K’

n

= 3.0×10

8

N/m,

K’

s

= 2.0×10

8

N/m. The model parameters for other contacts with

intact MH bonds were determined as explained in Section 2.

A 40×80 cm virtual specimen was first generated using the

multi-layer with under-compaction method (Jiang et al. 2003).

The resulted specimen with an initial planar void ratio of 0.21

was composed of 6000 disks with radii ranging from 6 to 9 mm,

forming a gradation curve shown in Fig. 3(b). The specimen

was consolidated by applying an isotropic pressure of 1 MPa

until force balance was maintained. The gravity was ignored in

the whole simulation. Bonds were then assigned to the contacts

of particles. As the force system was balanced, the top wall

moved downward at a speed of 5% per minute to simulate the

displacement-controlled shearing process. Frictionless rigid

walls were used in the simulation in stead of flexible walls to

reduce the computational time. The boundary type selected will

not affect the stress-strain response, while it however will

change the formation of shear bands.