1012

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

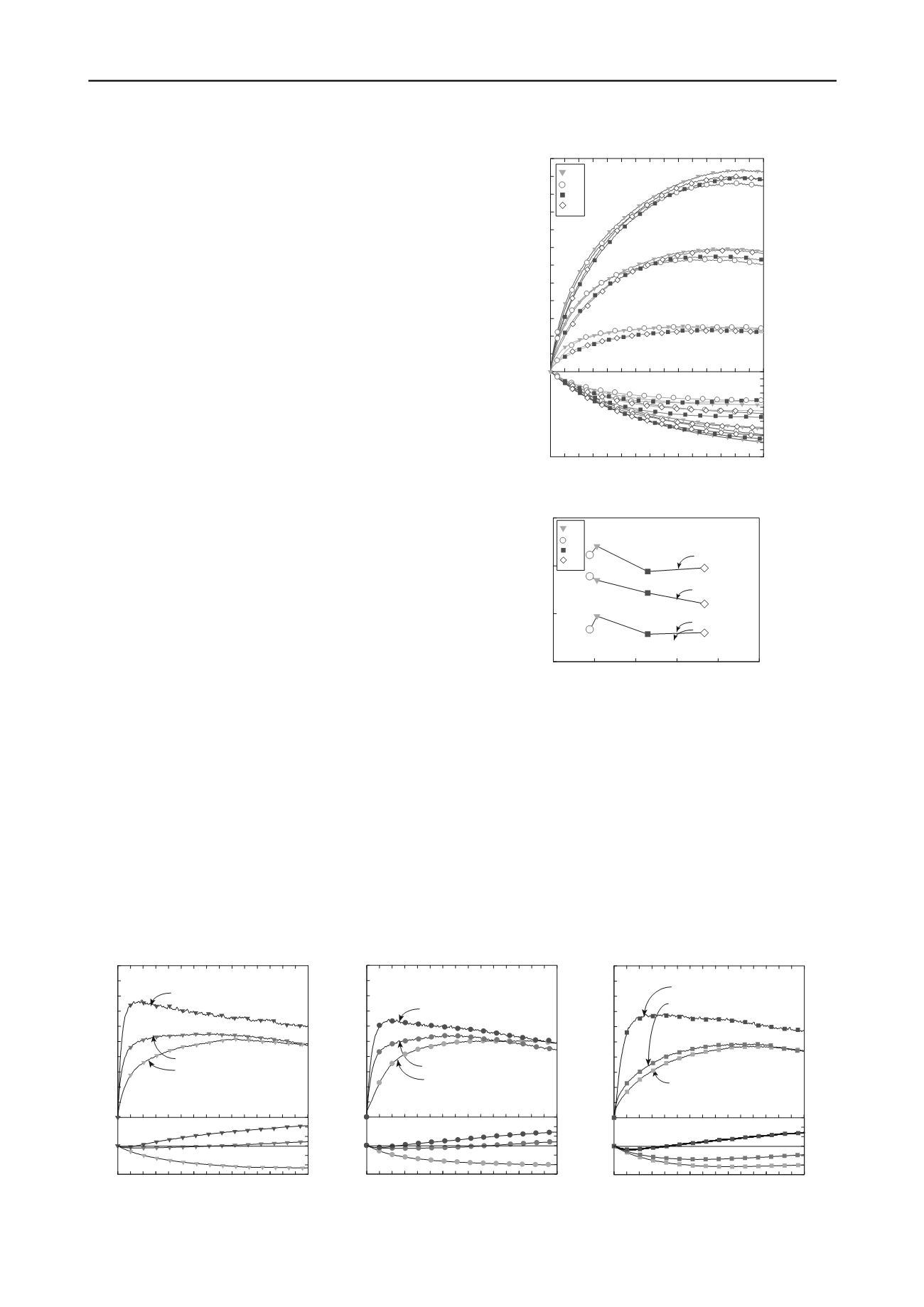

Production of MH bearing sands and their shear tests were

conducted using the temperature-controlled high-stress triaxial

testing apparatus (Hyodo, et al.2008). For the simulation

material, MH was formed in these host sands with 50%, 30%

and 0% degree of MH saturation. From the results of density

tests on natural cores from Nankai Trough, the porosities of the

simulation materials were set as

n

=40% and 45%. In this paper,

only the results of

n

=45% are presented. The method of

formation of MH in the simulation materials is as follows.

Firstly, an initial water content equivalent to the desired degree

of MH saturation was prepared and then an unsaturated

specimen, with diameter 30mm and height 60mm, was made

using tamping to a given density. Next, the specimen was set in

the cell of the apparatus and methane gas was injected into the

specimen for 24hr at 10MPa pore water pressure, 13MPa cell

pressure and at a temperature of 5

℃

to form the MH. After

stopping the methane gas injection and confirming the

formation of MH, the specimen was filled with pure water in

order to saturate it. A given effective stress was then applied

and shear tests were performed under drained conditions with a

rate of shear of 0.1%/min. After the shear test, the pore pressure

was decreased to a level outside of the MH stability boundary in

order to dissociate the MH which had been produced. The

quantity of MH was measured and the degree of MH saturation

was calculated by this amount of dissociated gas. The triaxial

test results for host sands Ta, Tb, Tc and Td with an initial

porosity of

n

=45%, under an effective confining stress of

1MPa, 3MPa and 5MPa are presented in Figure 2. In the figure,

the initial stiffness and residual strength slightly decreases with

increasing fines content, however there is no marked difference.

Volumetric strain induced by shear appears on the contractive

side and increases with increasing fines content and confining

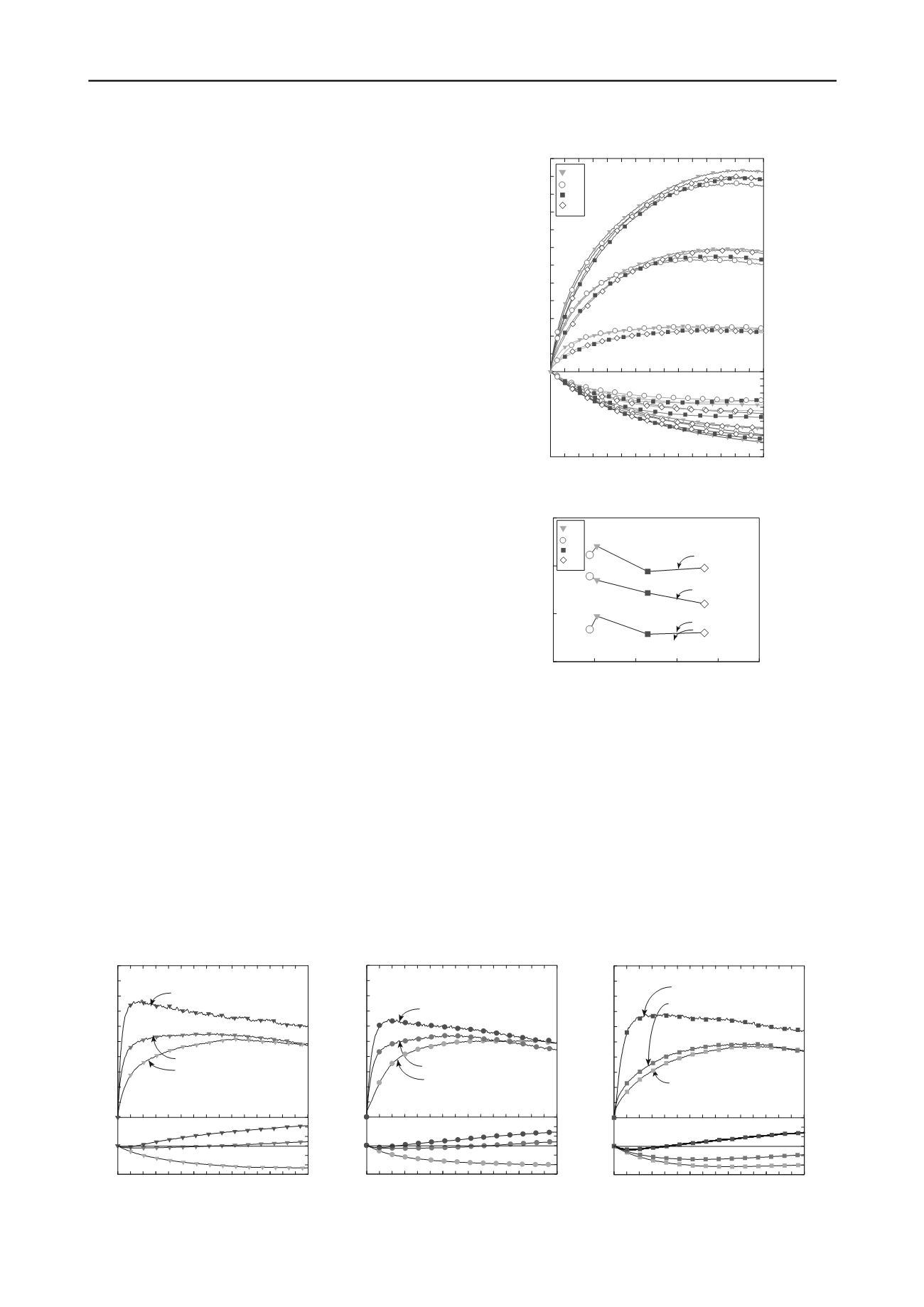

stress. Figure 3 shows the variation of the secant modulus at 1%

axial strain against fines content for each material with each

confining stress. It can be seen that there is a trend for the secant

modulus to decrease with increasing fines content at all

confining stresses. However, this is not true for Ta and Tb, due

to the effect of their mean particle size. Fig.4(a)-(c) show the

shear testing results for MH bearing sands by using Ta, Tb and

Tc as host sands. Tests were performed at a porosity of

n

=45%

with effective confining stress of 1MPa at various degrees of

MH saturation. From the figures it can be observed that initial

stiffness and peak residual strengths increased as the degree of

MH saturation increased. Corresponding volumetric strain

increases and behaves in a more dilative manner with increasing

degrees of MH saturation. In Figure 5, the difference between

the peak strength of MH bearing sand and the strengths of the

host sands, at an axial strain corresponding to the peak value of

MH bearing sand, are normalized by effective confining stress

and then plotted against the degree of MH saturation. It can be

observed that the strength increased rapidly when the degree of

MH saturation passed 30%, and the rate of increase decreases in

order of Ta, Tb and Tc. It is therefore obvious that the grain size

distribution affects the cementation effect of MH.

4 SHEAR CHARACTERISTICS OF MH BEARING SANDS

BY HIGH-STRESS PLANE STRAIN SHEAR TESTING

An overview of the testing equipment (Yoneda et al. 2011) is

shown in Figure 6. This apparatus can control temperatures and

pressures equivalent to an MH reservoir in deep seabeds.

Additionally, observation windows are installed in front of and

behind the specimen in order to allow the local deformation of

the specimen during shear tests to be measured. The specimen is

a cuboid with 80mm width, 60mm thickness and 160mm height.

A 5mm

x

5mm mesh was drawn on the membrane in front of

the observation window. The observation was performed using

a digital camera(g), which took pictures according to a timer

controlled by a remote system. An LED(h) was installed to

brighten the pressure cell(i), which allowed the specimen(e) to

Figure 2 Variation of deviator stress and volumetric

s

train

against axial strain for host sands

0

10 20 30 40 50

0

1

2

3

T

a

T

b

T

c

T

d

Secant modulus

E

(

(MPa)

Fines content

F

c

(%)

n

=45%

c

'=1MPa

c

'=3MPa

c

'=5MPa

Figure 4 Variation of deviator stress and volumetric

s

train against axial strain for methane hydrate bearing sands

(b) T

b

(a)T

a

(c) T

c

0

1

2

3

4

5

6

0

-6

0

10

20

30

Volumetric strain

v

(%)

Axial strain

a

(%)

Deviator stress

q

(MPa)

T

b

c

'=1MPa

S

MH

=0%

n

=45.5%

S

MH

=31.1%

n

=45.5%

S

MH

=47.4%

n

=45.3%

0

1

2

3

4

5

6

0

-6

0

10

20

30

Volumetric strain

v

(%)

Axial strain

a

(%)

Deviator stress

q

(MPa)

T

c

c

'=1MPa

S

MH

=0%

n

=45.0%

S

MH

=24.3%

n

=45.2%

S

MH

=58.6%

n

=44.9%

0

1

2

3

4

5

6

0

-6

0

10

20

30

Volumetric strain

v

(%)

Axial strain

a

(%)

Deviator stress

q

(MPa)

T

a

c

'=1MPa

S

MH

=0%

n

=45.1%

S

MH

=24.6%

n

=45.5%

S

MH

=43.7%

n

=44.8%

Figure 3 Relationship between secant modulus

and fines content

0

4

8

12

12

6

0

0

10

20

30

Volumetric strain

v

(%)

Axial strain

a

(%)

Deviator stress

q

(MPa)

S

MH

=0%

n

=45%

a

=30%

T

a

T

b

T

c

T

d