1006

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Figure 5. Experimental probability transition of a particle

d

i

in to a

particle

d

j

.

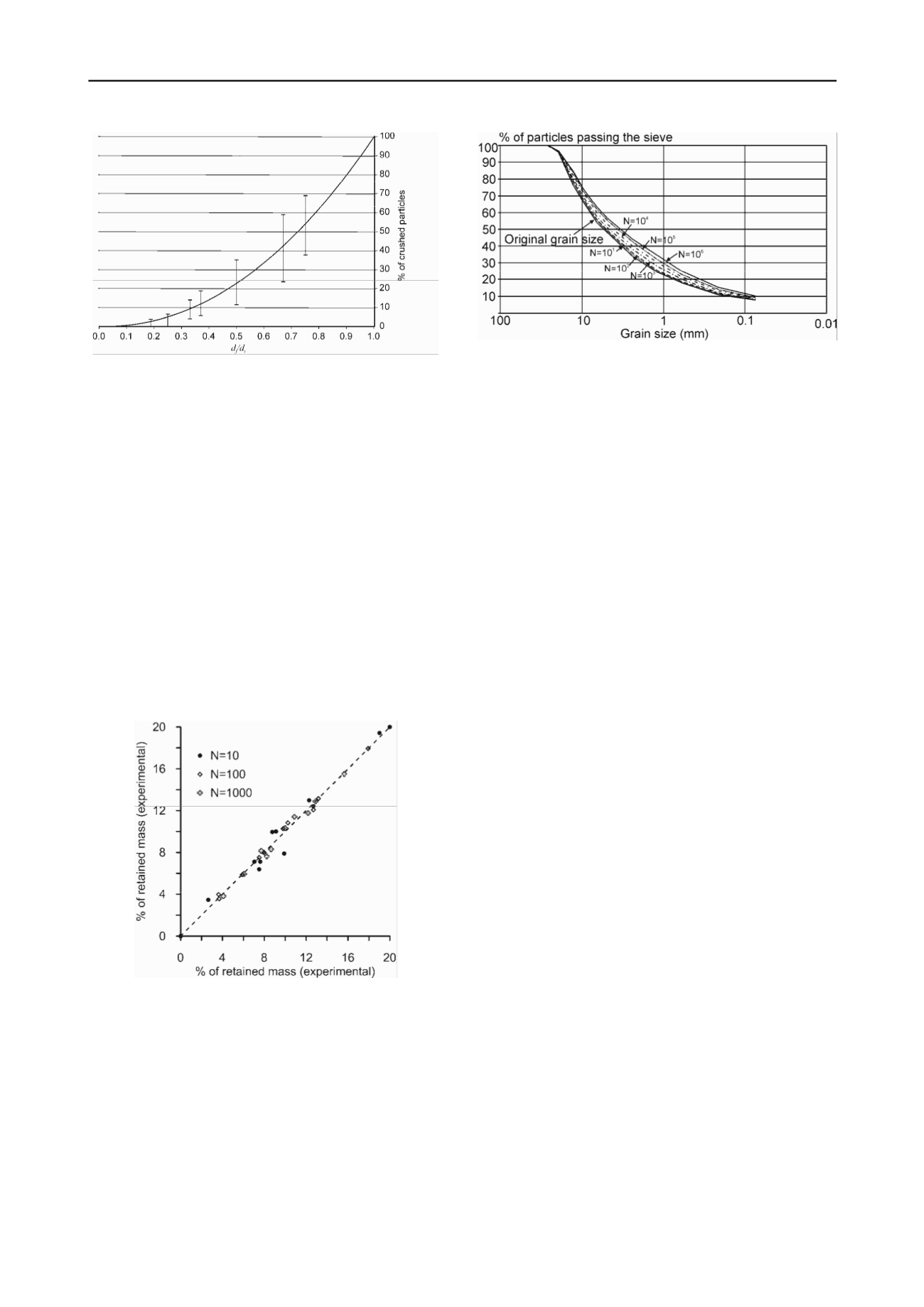

Figure 7. Evolution of the grain size distribution for different number of

loading cycles.

4 CONCLUSION

Elements

p

ij

of the transition probability matrix can be

calculated as follows:

) , (

j

i

f

ij

dd Beta

p p

(19)

Finally the evolution of the grain size distribution of a

granular mixture results from the product of the transition

probability matrix (transposed) and the grain size distribution

before the loading cycle:

This paper presents a new model to assess the process of

changes of the granular material properties as fracturing and

abrasion occur as a result of cyclic loading. The model has

shown that it can accurately predict the deterioration process of

unbound granular materials subject to cyclic loading. This

analytical model is based on the theory of poly-disperse

mictures and therefore calculations up to high number of

loading cycles can be performed without the difficulties of

discrete element modelling. The results show very good

agrement with the experimental tests illustrating the possibilities

of this new model.

1

Ni

T

Ni

y

y

(20)

5 REFERENCES

3 RESULTS

To verify the predictions of the model three different granular

materials were tested in a gyratory compactor. This apparatus

reproduce the stress rotation during field compaction of granular

layers. Compaction was performed to different number of

loading cycles and then the grain size distribution was analyzed.

Bolton M D (1999). The role of micro-mechanics in soil mechanics

Proceedings of the international workshop on soil crushability.

Yamaguchi, Japan, 58-82

Bolton M D, McDowell G R Clastic mechanics IUTAM Symposium on

Mechanics of Granular and Porous Materials. Cambridge, 35-46

De Larrard F (2000) Compacite et homogeneite des melanges

granulaires. In: L. C. d. P. e. Chaussées (ed) Structures Granulaires

et Formulation des Betons, 1st edn. LCPC.

Feda J (2002) Notes on the effect of grain crushing on the granular soil

behaviour. Engineering Geology, 63(1-2): 93-98

Hagerty M M, Hite D R, Ullrich C R, Hagerty D J (1993) One-

dimensional high-pressure com-pression of granular media. Journal

of Geotechnical Engineering, 199(1): 1-18

Hardin B O (1985) Crushing of soil particles. Journal of Geotechnical

Engineering, 111(10): 1177-1192

Lade P V, Yamamuro J A, Bopp P A (1996) Significance of Particle

Crushing in Granular Ma-terials. Journal of Geotechnical

Engineering 122(4): 309-316

Lee, D. M. (1992). "The angles of friction of granular fills," Ph.D.

dissertation, University of Cambridge.

Lobo-Guerrero S (2006) Evaluation of crushing in granular materials

using the discrete element method and fractal theory. University of

Pittsburgh, Pittsburgh, PA.

McDowell G R, Bolton M D (1998) On the micromechanics of

crushable aggregates. Géotechnique, 48(5): 667-679

Nakata Y, Hyde F L, Hyodo M, Murata H (1999) A probabilistic

approach to sand particle crushing in the triaxial test. Géotechnique,

49(5): 567-583

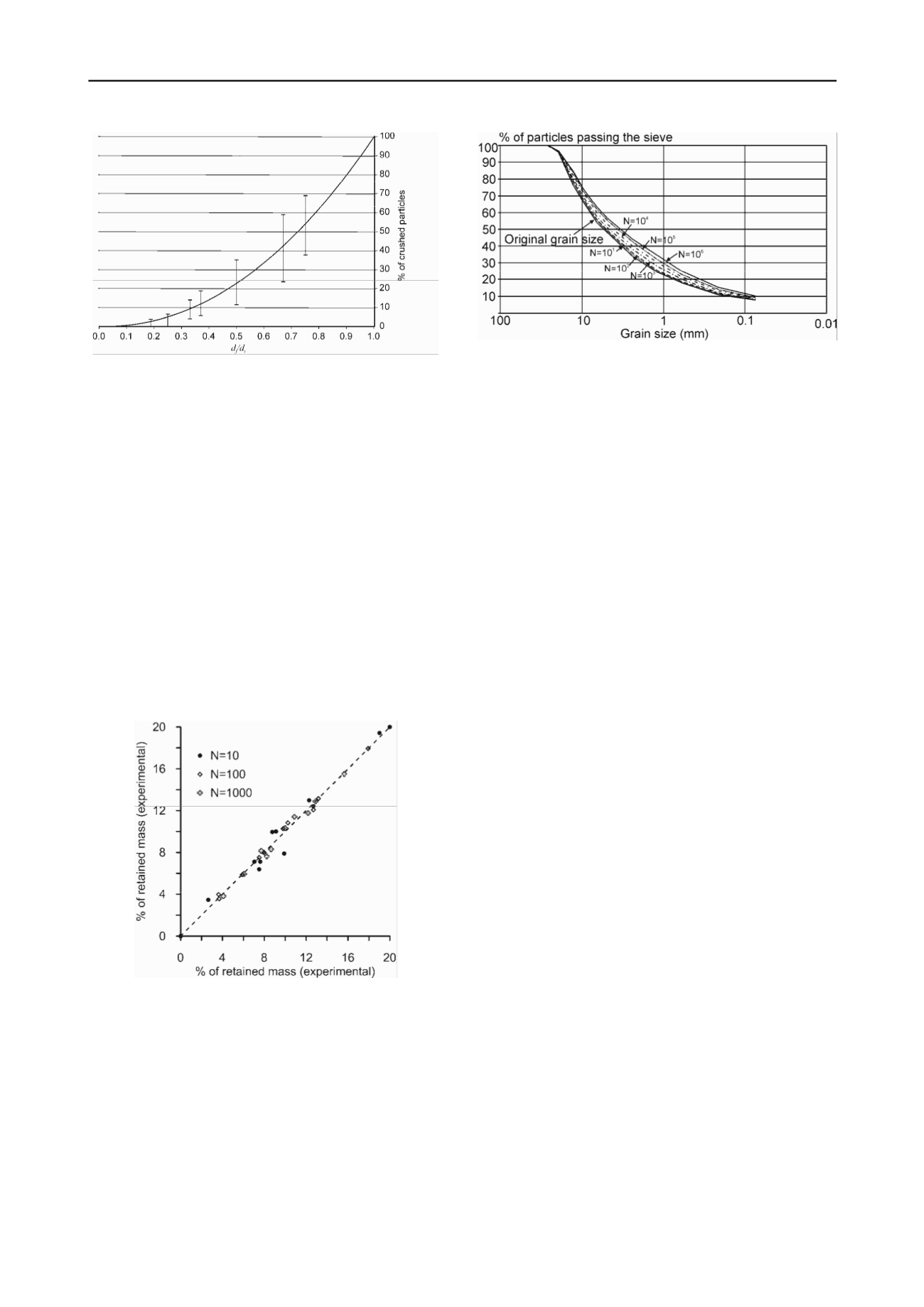

Figure 6. Comparison between experimental and model results.

Figure 6 present a comparison of the experimental and

numerical tests for one of the tested materials. This figure

shows the mass of particles retained in each sieve size. Each

point in the figures corresponds to a particle size at the end of a

specific number of loading cycles. These figures show the very

good agreement between the model and the experimental data.

Nakata Y, Hyodo M, Hyde F L, Kato Y, Murata H (2001) Microscopic

particle crushing of sand subjected to high pressure one-

dimensional compresion. soils and Foundations, 41(1): 69-82

Ocampo M (2009) Fracturamiento de partículas en materiales

granulares sometidos a cargas cíclicas con rotación de esfuerzos.

Universidad de Los Andes, Bogotá D.C.

Figure 7 represent an extrapolation of the results of the

model up to a million of loading cycles showing the capacity of

this analytical model to calculate the evolution of grain size

distribution when a high number of cycles are applied to the

material.

Yamamuro J A, Lade P V (1996) Drained Sand Behavior in

Axisymmetric Tests at High Pres-sures. Journal of Geotechnical

Engineering, 122(2): 109-119