996

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

3.4

Exploring micromechanics analytically

The contributions by

Shao et al. (2013)

and by

Caicedo et al.

(2013) both present theoretical developments.

Shao et al. (2013)

provide an analytical evaluation of the effect of pore water

pressure on the effective stress in the soil skeleton for saturated

and unsaturated media. Even though the developments are

certainly correct, the objective and conclusions of this study

appear somewhat obscure to the reporter.

The paper by

Caicedo et al. (2013)

reports an interesting

theoretical development regarding grain crushing – which is of

particular relevance when granular materials are used in

engineering structures such as paved roads, railroads and

highway embankments. The analytical model developed by the

Authors aims to predict the evolution of the grain size

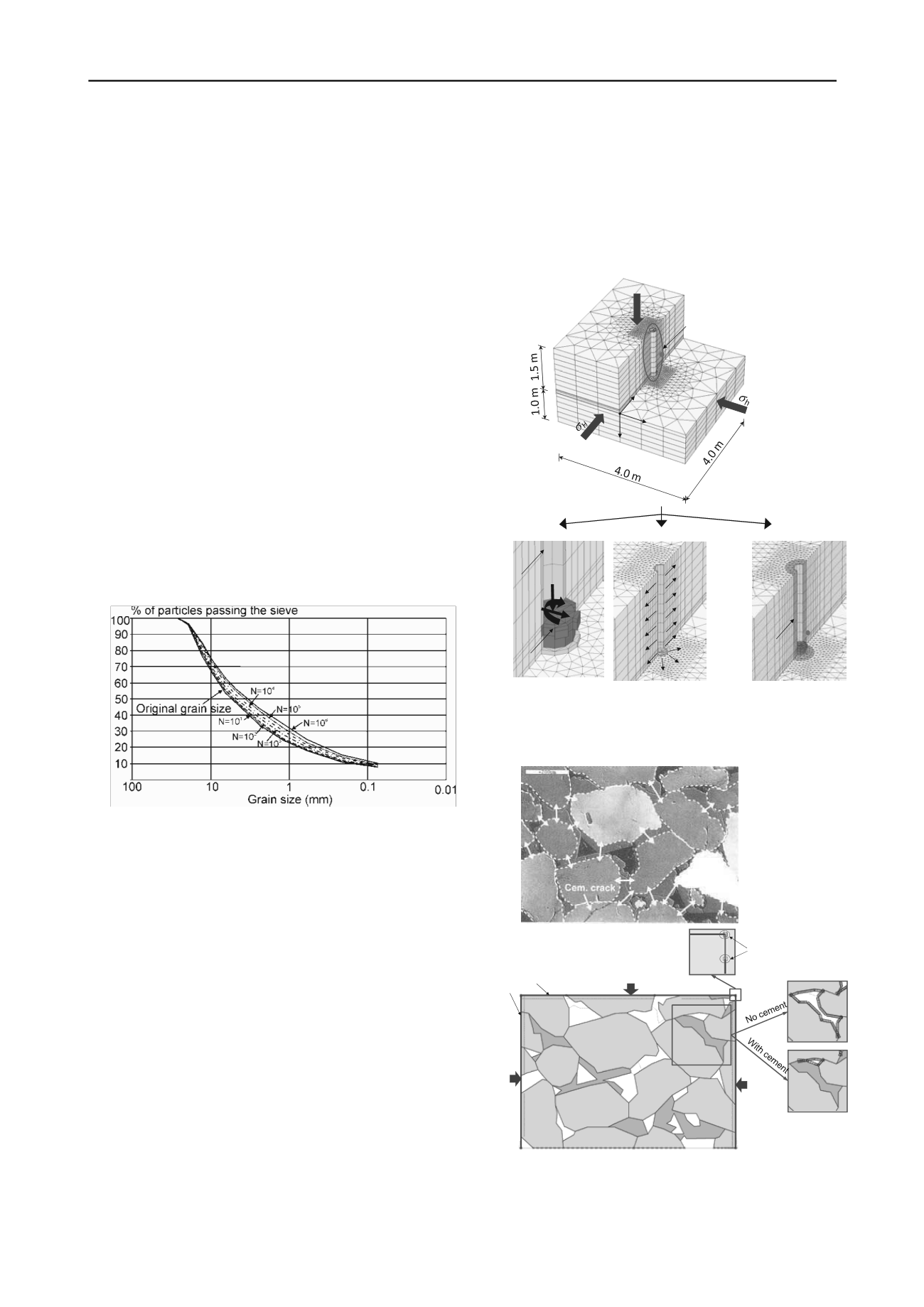

distribution during loading. As an example, Fig. 13 shows the

evolution of the grain size distribution predicted by the model

after a very high number (up to one million) of loading cycles.

The model uses the theory of poly-disperse mixtures proposed

by De Larrard (2000), and predicts grain breakage by

combining the geometrical relevance of a size class of grains

with a statistical distribution of strength (given by a Weibull

distribution). When a particle breaks, the size of its fragments is

determined through a Markov process. The combination of

these elements appears to capture grain breakage successfully –

the application of this model to experimental results is shown to

give very good agreement. It is the Authors’ contention that

their model is a valid alternative to DEM, which can also deal

with grain crushing but is computationally very expensive.

Figure 13. Evolution of the grain size distribution for different number

of loading cycles

(Caicedo et al. 2013).

3.5

Engineering applications for energy production

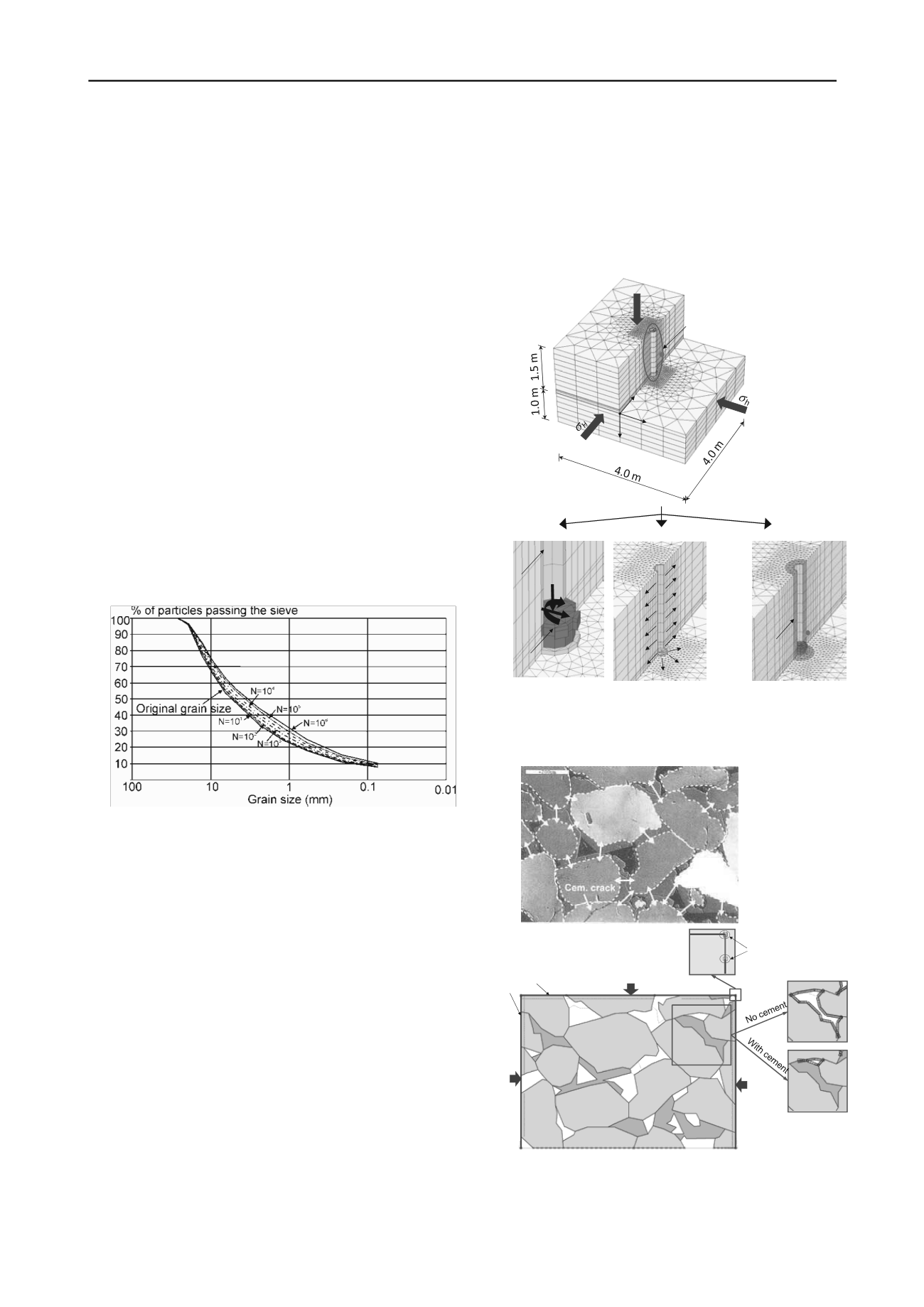

Interestingly, there is only one contribution to this session

making use of the Finite Element Method (FEM). This is the

numerical study by

Khoa et al. (2013)

, which tackles the

analysis of the damage induced by drilling and coring

operations in the rock surrounding a wellbore. This is a two-

scale analysis, in that a large scale 3D FE model is first used to

simulate the stresses induced by drilling and coring (see Fig.

14); these stresses are then injected into a 2D micro scale FE

model, the geometry of which is directly built on experimental

SEM observations of well cemented sandstone. The results

show that the micro FE model is able to pick up mechanisms of

failure that simply do not feature in the macro-scale continuum

model.

When going to the smaller scale analysis, the Authors

implicitly assume that a Mohr-Coulomb elastic perfectly plastic

model is capable of reasonably describing the stress state at the

micro scale. It should be mentioned that the paper does not give

any detail as for the determination of the mechanical parameters

used in the analysis at the micro scale. Moreover, strong

assumptions are made on the geological history (

e.g

., the grain

skeleton carries the load before getting cemented – which

means that as soon as unloading occurs, the inter-granular

cement gets loaded in tension and fails).

The approach adopted by Khoa and coworkers is certainly

original and interesting. However, although the analysis

presented in this study is indeed performed at two different

scales, it should be stressed that the only link between the two

scales is the stress in one point.

Figure 14. Full 3D FE modeling of different loads due to drill bit

torque and axial load, mud-flow into formation and temperature

change within one radius from wellbore wall

(Khoa et al. 2013).

Figure 15. Cathodoluminescence SEM picture (top) from Storvoll &

Bjorlykke (2004) and equivalent 2D micro FE model (bottom) used

for studying induced damage around a wellbore during drilling and

coring operations

(Khoa et al. 2013)

.

WOB

F

bit

From drill bit

Drill bit

Mud cake

TOB

From

temperature

T within 1

radius from

wellbore side

From mud

v

Borehole

(r ×h : 0.108 × 1.5 m

infiltration of

mud-fluid

y

A

y

z

x

A

Vertical stress,

V

Horizonatl stress,

h

Horizonatl stress,

h

Pore pressure,

u

Rotation

fixities

Beam

elements