995

Technical Committee 105 /

Comité technique 105

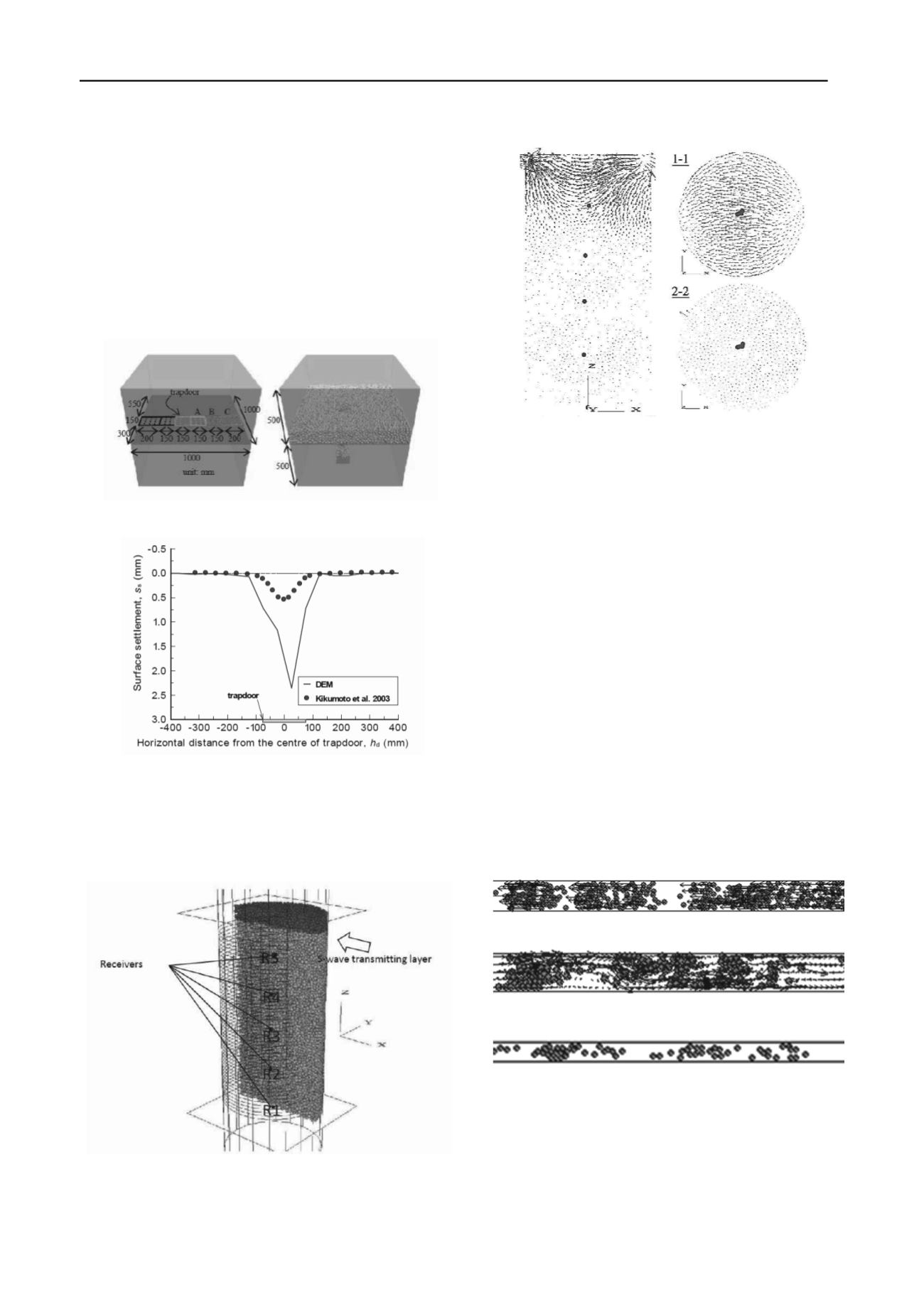

particle size, and mean stress – which is of course possible, yet

difficult, with laboratory experiments. Cylindrical assemblies of

particles are subjected to shear wave excitation at one end and

axial propagation velocities are measured (see Fig. 10).

Micromechanical observations of the specimen are presented

and analyzed in terms of particle velocity vectors, which

highlight the complex motions of individual particles during

wave propagation. As an example, velocity vectors in Fig. 11

show dominant S-wave motion (from right to left) in the central

area of the specimen, while minor P-wave motion is observed

on the sides (with the particle on the right moving downwards

and the particle on the left moving upwards).

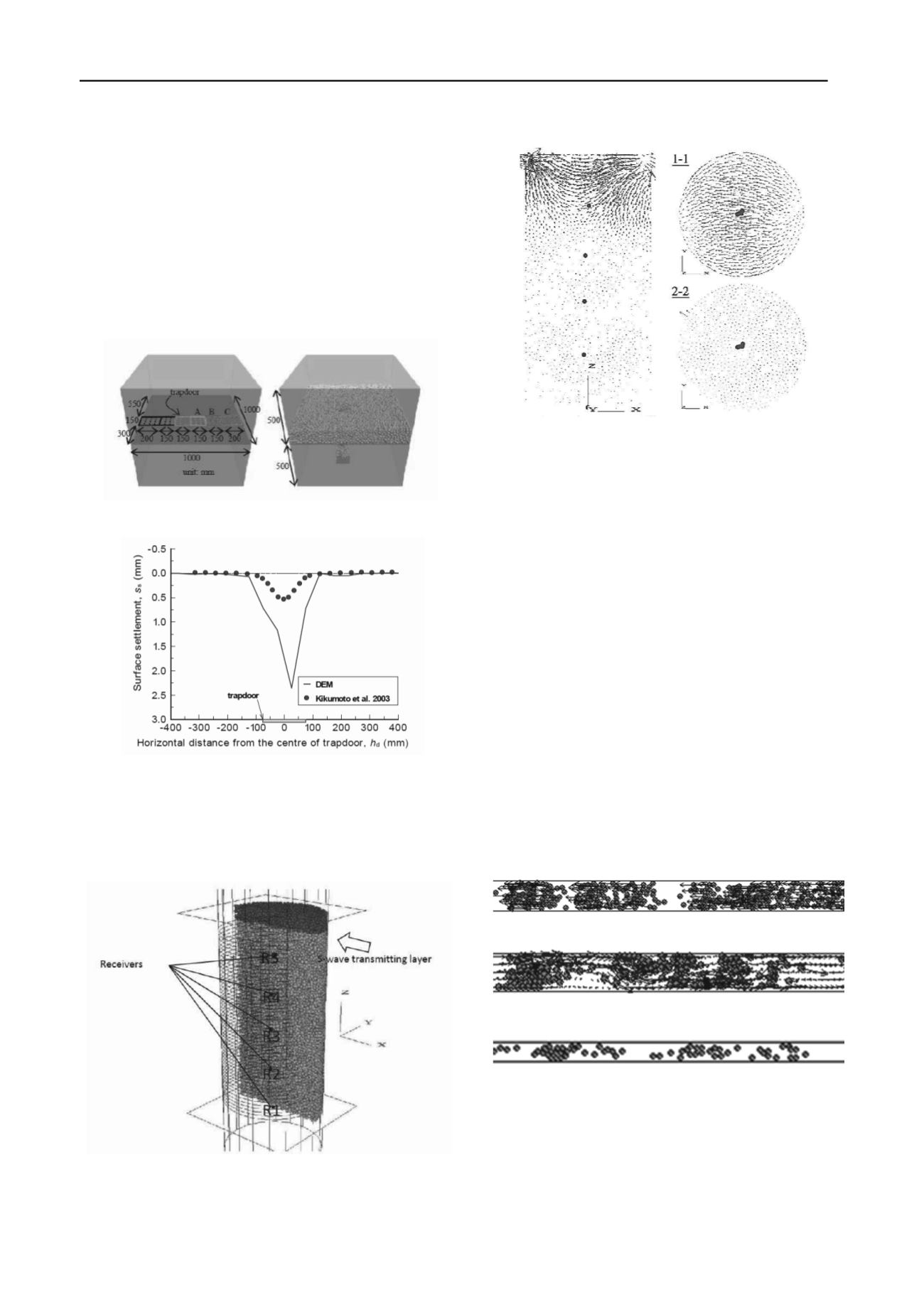

(a)

(b)

Figure 9. (a) Trap door and gravity flow testing apparatus (left), and

DEM simulation (right); (b) Surface settlement of the sand above the

center of the trapdoor when dt = 2.0 mm, layer thickness 150 mm

(Kikkawa et al. 2013).

.

Figure 10. DEM specimen with S-wave transmitting layer and

receivers – for clarity, only half of the specimen is shown (

Ning &

Evans 2013

).

Figure 11. Particle velocity vectors on different cutting planes of a

DEM specimen at a 10ms time point after excitation (

Ning & Evans

2013

).

The paper by

Tomac & Gutierrez (2013)

also uses DEM as a

tool for understanding processes, the focus of this nice study

being the flow of dense sand slurries within a narrow channel –

where “dense” means that the volumetric particle concentration

is greater than 10%, and “narrow” that the width of the channel

is less than 5 times the particle diameter. In these flow

processes, clogging and velocity retardation often occur and are

governed by sand concentration and slurry flow rate. The

numerical model developed by the Authors couples the Discrete

Element Method with computational fluid dynamics to study (in

2D) this flow process. A user-defined contact model is

developed to capture the non-linear collision of submerged

particles and walls. The theory of lubrication is also used to

formulate a damping effect which is associated with the model.

Some key results of this study are shown in Fig. 12. Maximum

sand concentration (

i.e

., the concentration at which sand

transport is not possible and the flow stops) is shown to depend

on the ratio of channel width to particle diameter, as well as – to

a lesser extent – on fluid pressure. Since solid and fluid phases

have different average velocities, it is hard to average and come

up with a unique slurry flow characterization at this point; the

Authors conclude that a more comprehensive study is needed to

address this issue.

Figure 12. (top) Clogging of sand in 4mm wide channel at initial

volumetric sand concentration c

v

= 0.49 with particles velocities

vectors in direction opposite to the flow; (middle) Unstable flow with

formation of particles packs at initial c

v

= 0.39 in 4mm wide channel

with fluid flow velocity vectors around packs; (bottom) Formation of

particles packs at initial c

v

= 0.28 in 2mm wide channel (

Tomac &

Gutierrez 2013

).