983

Technical Committee 104 /

Comité technique 104

4 CENTRIFUGE SETUP

4.1

Centrifuge Package and Instrumentation

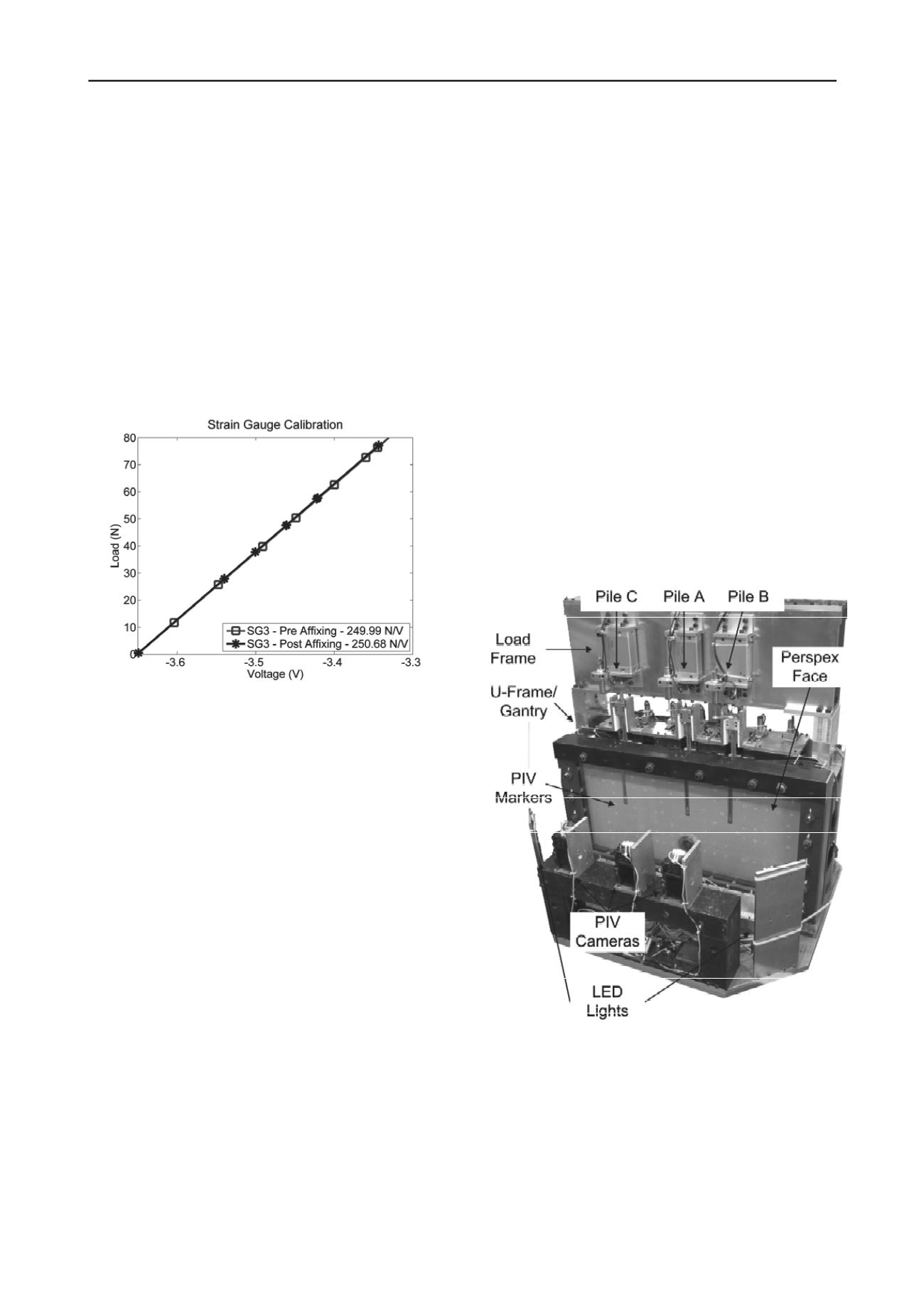

The centrifuge setup consisted of a strongbox, with a loading

frame/system and PIV cameras/lights (see Figure 4). The

strongbox had a Perspex face against which the piles rested, a

steel U-frame and an aluminium back, which provided very

high stiffness boundaries around the soil.

The PIV markers were calibrated against known target

positions. The pile displacements measured through PIV, were

also monitored with linear variable differential transformers

(LVDT’s).

To verify the values provided by the head and base load

cells, Novatech F259 Miniature Diaphragm 1 kN Loadcells

were attached to the loading system so that the change in head

load could be measured independently.

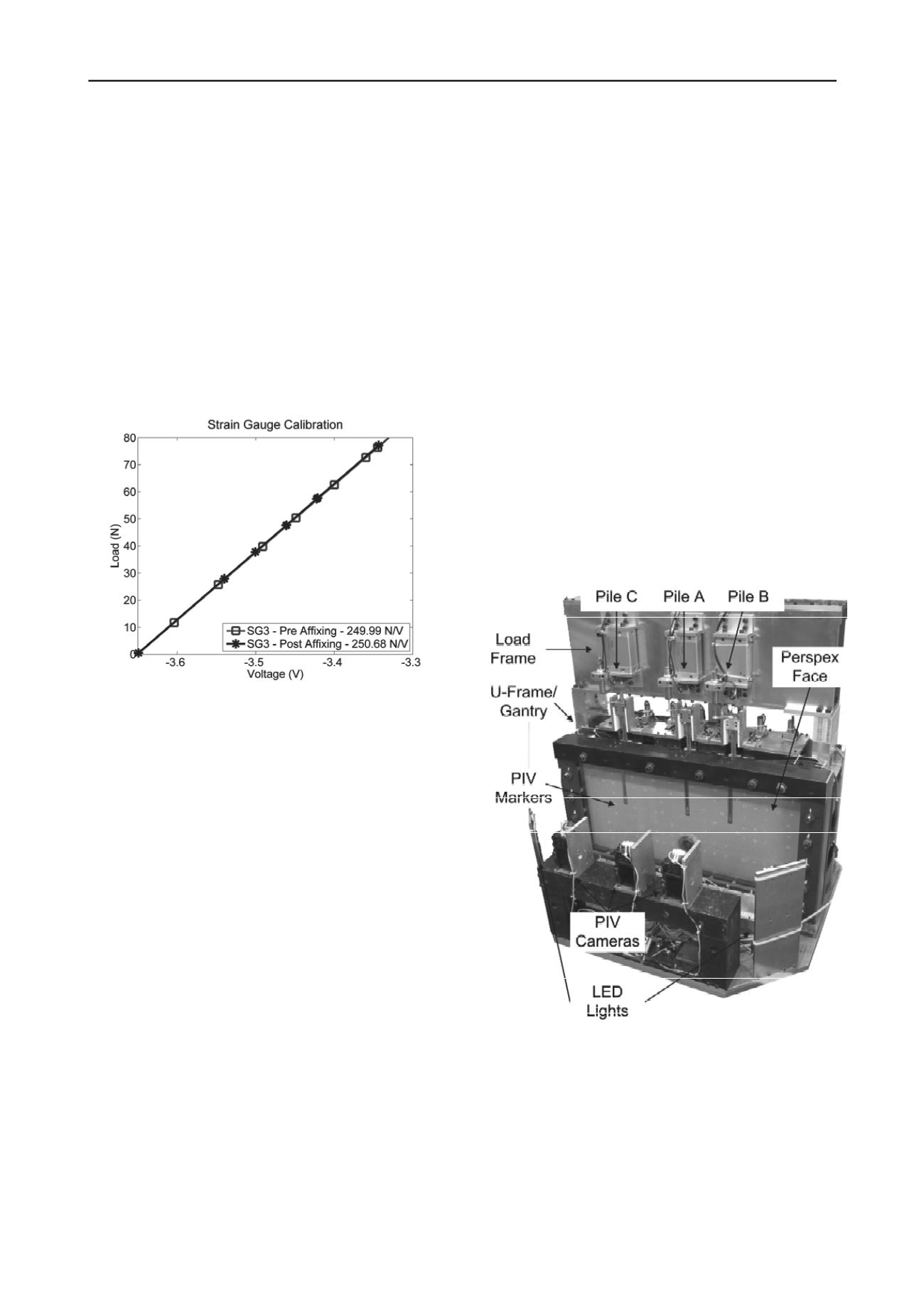

Figure 3. Pile calibration – before affixing to the pile body and after

affixing to the pile body.

4.2

Sand

The piles were placed firmly against the Perspex face and the

sand rained down over them. Fraction E Leighton Buzzard

Sand was used in the experiments at a relative density of 76%

±2%.

4.3

Experimental Procedure

Piles A and B (see Figure 4) were used to provide data on the

effects of tunnelling on bored piles, whereas Pile C was used to

provide details of the pile capacity and load settlement response.

The centrifuge was accelerated slowly to the desired 75g,

with photographs being taken from each of the PIV cameras at

various stages. The pile loads were monitored during the

acceleration phase after which loads were added to the pile

heads using a specially designed loading system, which applies

only the dead load of a pile cap for Piles A and B.

Pile C had a different loading system which also did not

apply any load until the desired 75g had been reached. This pile

also had a pile cap but with a loading pin capable of applying a

head beyond that of the cap dead weight.

All the piles were sleeved to the base (for details see

Williamson 2013) so that only the base component was a factor

in the pile loading.

5 RESULTS

5.1

Load Cell Response

The response of the load cells to the changing head load for Pile

C is shown in Figure 5.

Clearly the comparison between the commercially available

Novatech head load cell and the response of the new strain

gauged load cells is very good compared with the ideal 1 in 1

slope. No greater than 8% variation between the different types

of load cell is found.

The variation between the head and base load cell response

is relatively constant at around 80 N between 420 N and 1000N.

It was found that the pile toe began to move away from the face

slightly at 1000 N and hence the divergence is likely to be

attributed to some high level bending to the base load cell.

Piles A and B operate at working loads of between 100 and

120 N depending upon the experiment. Within this range the

variation between the change in head and base loads is small,

but the incremental loading is shown to be linear. This would

perhaps indicate slightly higher amounts of bending on the head

load cell. The calibration factors for the head load cells though

linear were slightly less consistent throughout the tests than the

base load cells. It is thought that their shorter length and the

slight inconsistency in the contact point between the pile cap

and the load cell could have affected the calibration factor,

though it was shown to vary by no more than 10 % throughout

the test series.

Figure 4. Centrifuge setup – illustrating the piles, loading system and

PIV setup.