982

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 PILE SPECIFICATION

To produce a pile and pile loading system capable of high

quality bored pile behavioural simulation a wholly new design

was required of both the pile and the pile loading system.

2.1

Pile Cross Section

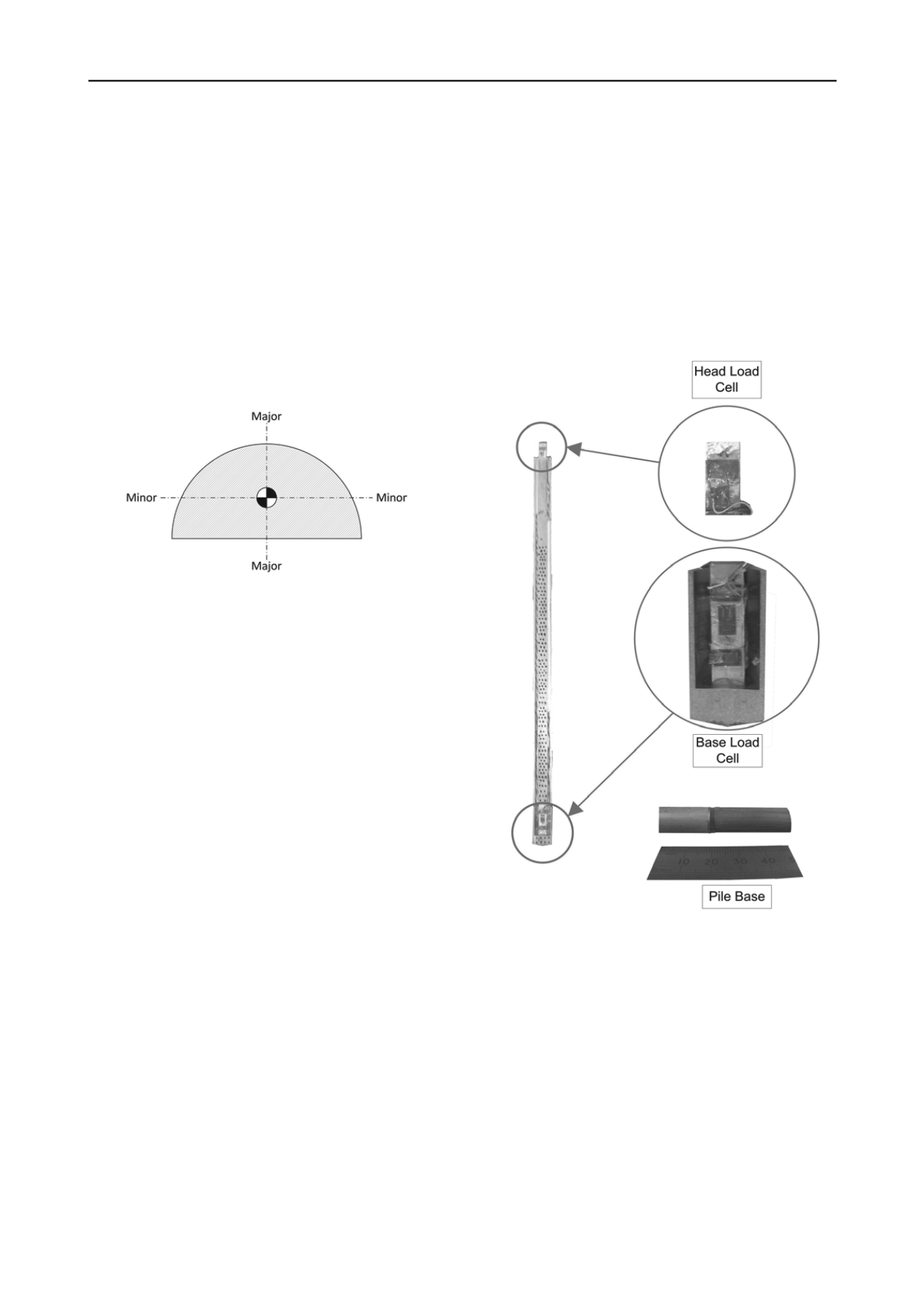

Researchers in the past have used a single wall to represent a

series of piles to simplify the problem to 2D plane strain (White

and Bolton 2004), while others have used square piles to

simulate the behaviour of circular piles.

Such solutions are not suitable for the problem type given

the inherent 3D nature of the problem and the significant edge

effects when using a plane of symmetry respectively. As such a

semi-circular design was deemed most appropriate to provide

the correct 3D stress and strain field around the pile.

Figure 1. Schematic cross section of plane of symmetry pile.

2.2

Axial Load Measurement

Shaft friction piles in the centrifuge have previously been

shown to produce inaccurate mechanisms for piles in sands.

The effect of shear band dilatancy on lateral stresses conditions

means that neither the load nor the mobilisation strain along the

shaft can be replicated concurrently (Lehane et al 2005).

To remove this error and to investigate a worst case scenario

of an end-bearing bored pile in sand, the shaft was sleeved

against friction.

Following on from this it was therefore only necessary to

measure the load at the pile head and base to ensure that the

sleeving was working.

In an attempt to reduce the errors associated with pile

bending on axial load measurement load cells situated along the

pile centroid were considered a suitable option.

2.3

Loading System

The pile loading system was designed to ensure that loading

remained through the centroid of the cross section and

simulated a bored pile. (This system is described in detail in

Williamson 2013).

2.4

Final Specification

The final specification was therefore set based on the

requirements described:

Pile to be semi-circular in cross section

Axial load measurement at head/base

Smooth face of shaft

Pile must remain in contact with symmetry plane

Loading through pile centroid

Load measurement along pile centroid

Loading to simulate bored pile behaviour

3 PILE DESIGN

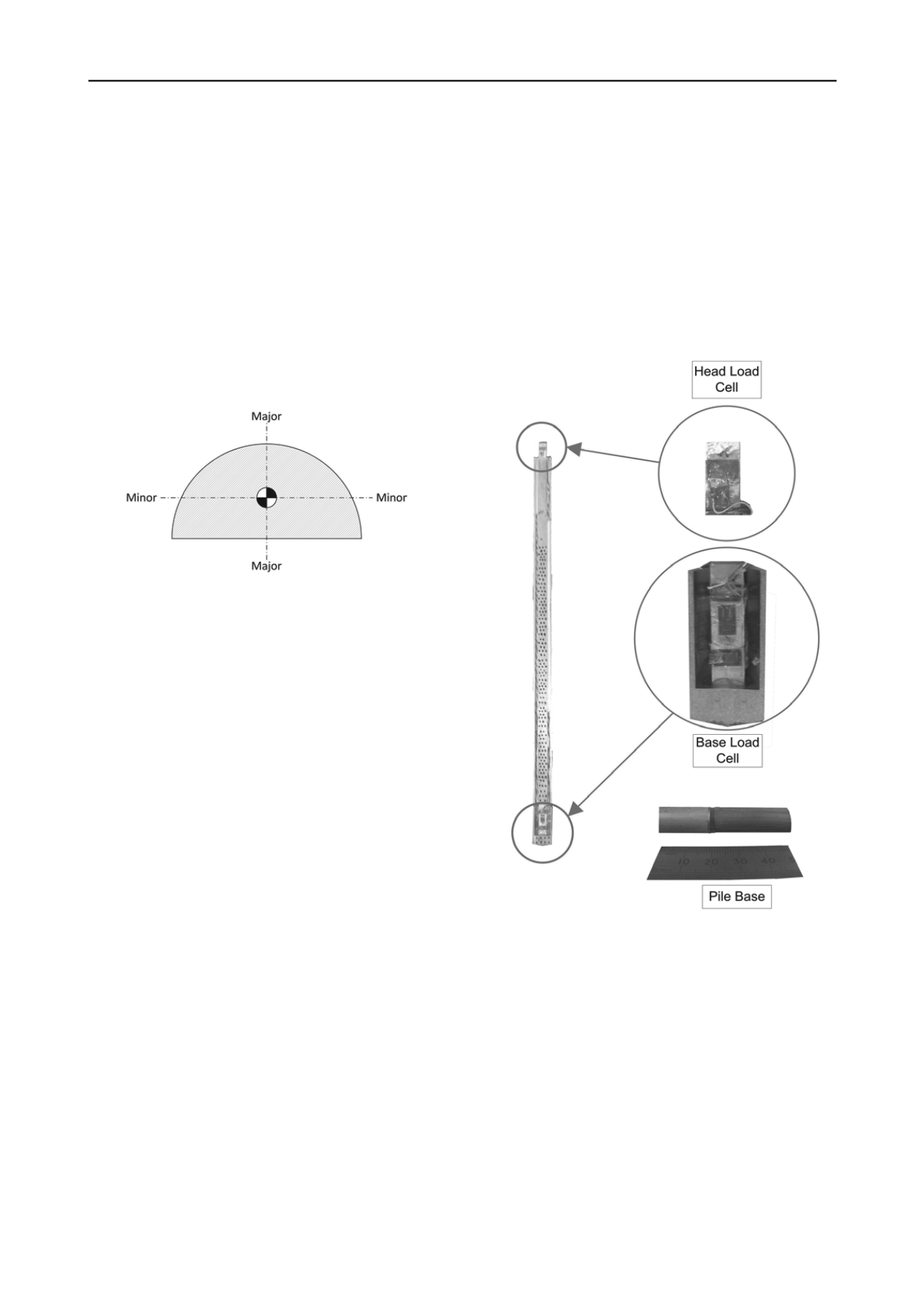

The final pile design is shown in Figure 2.

3.1

Pile Body

The pile body was machined from 2014-T6 aluminium, with

aluminium strain gauged load cells attached at the head and the

base. The pile was 15 mm in diameter and had an overall length

of 355 mm including the base and load cells.

3.2

Load Cells

The load cells were connected as full Wheatstone Bridges

with 4 No 350 Ω strain gauges used, 2 active and 2 inactive.

These load cells are situated precisely on the centroid of the

pile and connected securely between the pile shaft and base.

Figure 2. Final pile design.

3.3

Calibration

The pile load cells were calibrated before and after being

affixed into the piles. This was to investigate the effect of

bending during calibration resulting in the considerable free

length of the pile which has previously found to be an issue

(Marshall 2009).

A new calibration setup was designed to better replicate the

effective lengths in the centrifuge (~75 mm), which were small

in comparison with the overall free length of the pile (355 mm).

A comparison in the calibration factors between a load cell

calibrated individually and the same load cell within the pile is

shown in Figure 3. Clearly the agreement between the

calibration factors was good, and hence the system was then

taken forward to be used in the centrifuge where the effects of

high acceleration loads could be tested on the pile.