987

Technical Committee 104 /

Comité technique 104

3

RESULTS AND DISCUSSIONS

3.1

Bearing Capacity

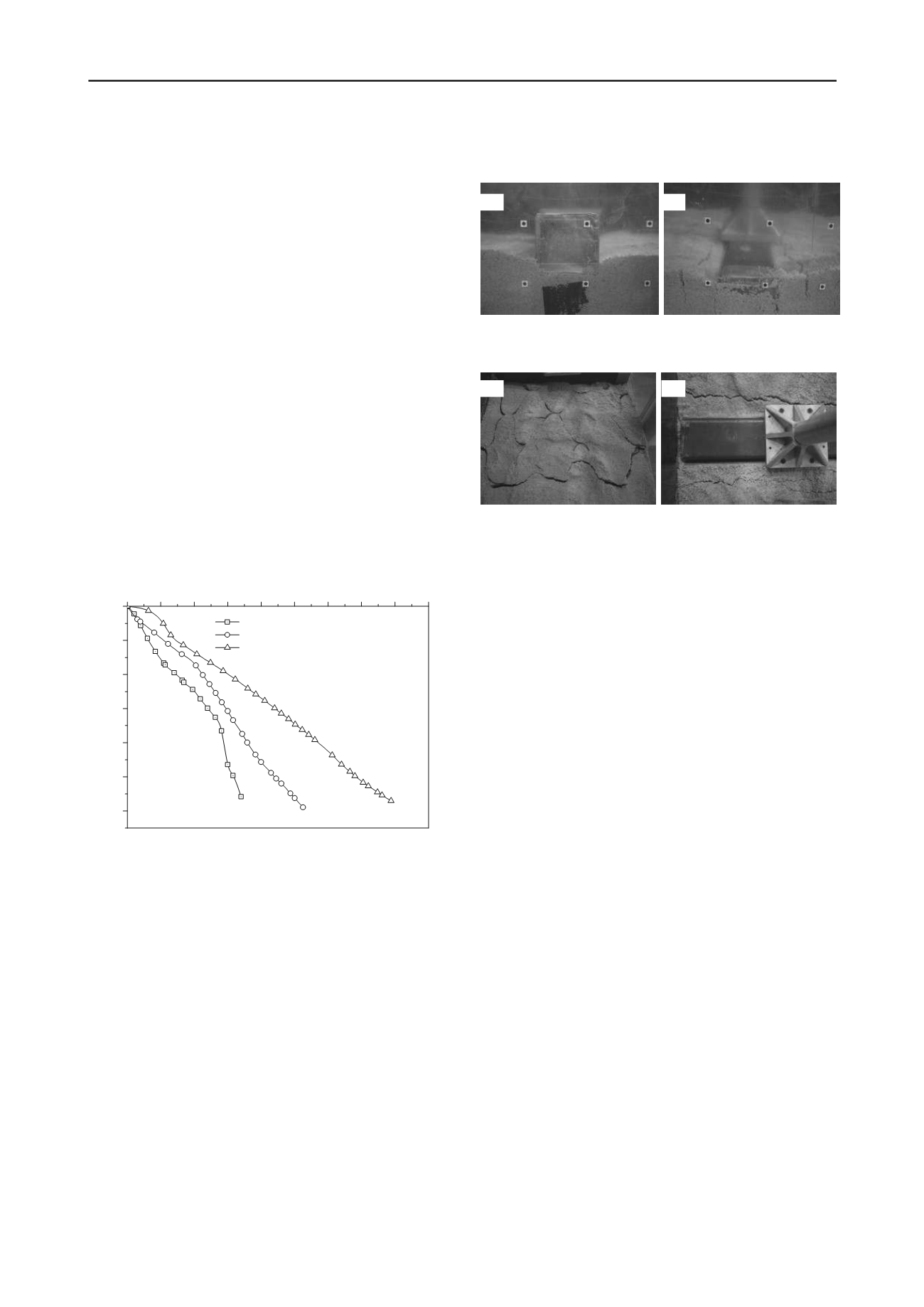

Figure 6 shows the relationships between load and settlement on

the footing. At a given settlement, the ground with more layers

of geocell is indeed of higher bearing capacity. Given 0.5 times

of the footing width (i.e., 0.5B) being the tentative design

settlement, the model tests show that the bearing capacities of

the ground reinforced with one-layer and three-layer geocell

mattresses are 1.4 and 2.2 times of the natural ground, without

any reinforcement.

The increase of bearing capacity with the geocell

reinforcement could be in line with the finding (Rajagopal et al.

1999) that the geocell filled with soil as an integrated material

equivalently becomes a cohesive material, and in the meanwhile

the angle of internal friction remains more or less the same as

the sand infills

. Therefore, in use of the Terzaghi’s

bearing

capacity theory (see the textbook of Das 1999), the extra

material cohesion adds the overall bearing capacity to the

ground. More importantly, unlike the shear strength contributed

by the frictional behavior becoming nominal as the effective

normal stress is reduced significantly with the increase of pore

pressure, the soil strength contributed by cohesion is

independent of external stress and water pressure, or it should

come to existence regardless of external stress condition.

60

50

40

30

20

10

0

0

25

50

75 100 125 150 175 200 225

Bearing load (kPa)

Footing settlement, s/B (%)

Without reinforcement

With one-layer geocell reinforcement

With three-layer geocell reinforcement

Figure 6. The relationships of load and settlement in the three

model tests.

3.2

Tension cracks

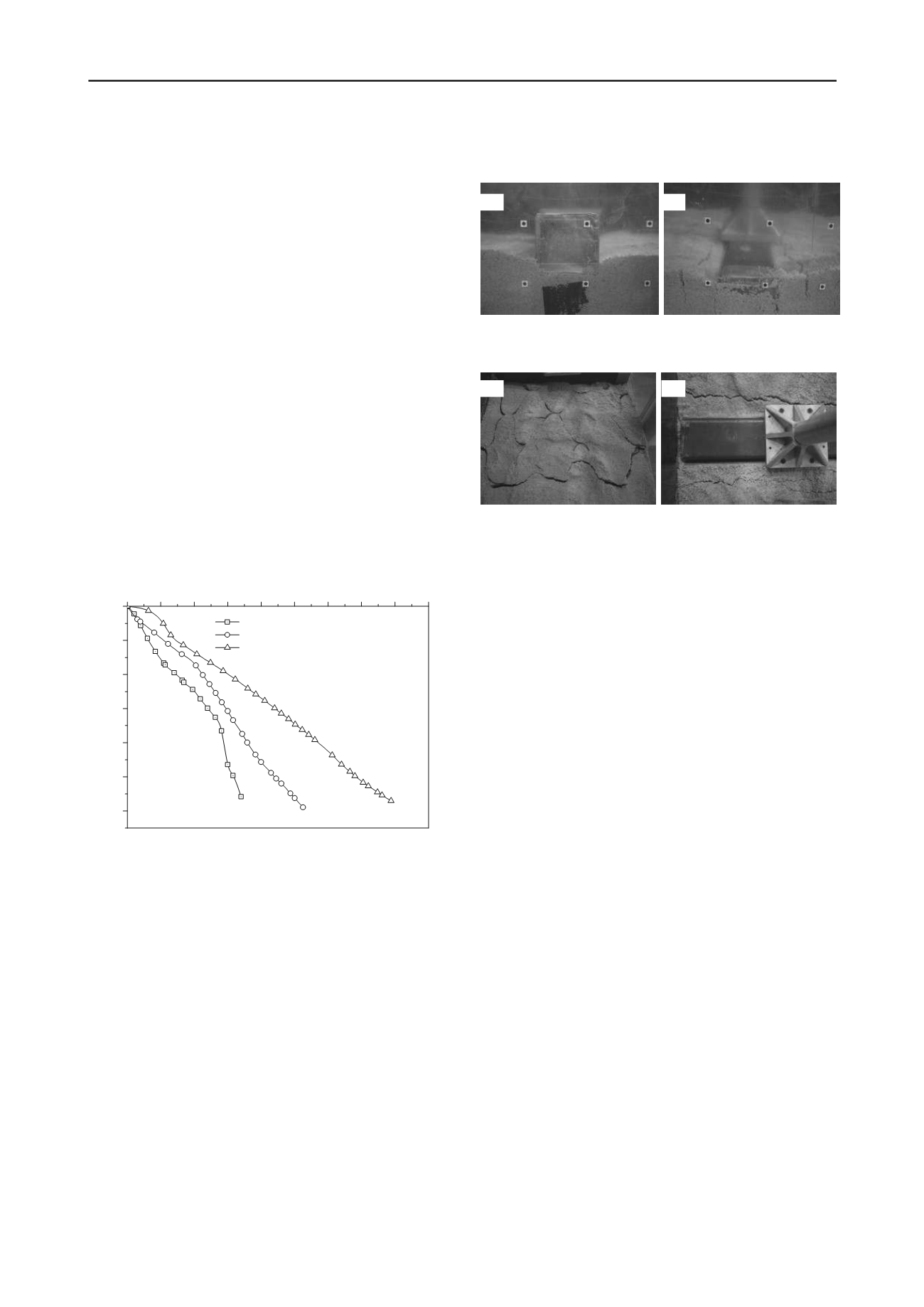

Figures 7 and 8 show the model ground surface with and

without the geocell reinforcement. For a “natural” ground

without reinforcement, major tension cracks were observed very

close to the footing. On the other hand, tension cracks in the two

reinforcement tests were found located much further away from

the footing, developing within the soil inside of the two ends of

the geocell mattress.

The development of cracks close to the footing in the non-

reinforcement test should be caused by the excessive pore water

pressure excited in the soil due to external loading. As the

lateral soil pressure less than water pressure, the tension crack

should start developing. However, as the soil is reinforced by

geocell, the deformed geocell under the footing tends to shrink

the size of pockets, resulting in a large passive earth pressure

that is larger than the water pressure, and therefore, the

development of tension cracks is not allowed around the footing

with the geocell reinforcement. This also possibly explains that

the cracks would develop within the soil at the two ends of the

geocell mattress, because the level of deformation in geocell is

relatively small and the corresponding passive earth pressure is

not large enough to compensate the excited pore pressure in the

water-immersed ground.

Figure 7. The side view of the model ground surface: (a) with

geocell mattress; (b) without geocell mattress.

Figure 8. The top view of the model ground surface: (a) with

geocell mattress; (b) without geocell mattress.

3.3

Ground surface settlement and heave

Figure 9 shows the ground surface settlement at different

distances from the footing captured with LVDTs. In the three-

layer geocell model, the ground surface tends to settle in a

relatively large area, owing to the geocell-soil mattress acting as

an integrated system. Simply speaking, the geocell-soil

composites far away from the footing were pulled down owing

to the geoc

ell’

s structure, causing the ground settlement also

observed relatively far from the footing.

On the other hand, for the natural ground without the geocell

reinforcement, the soil adjacent to the footing was pushed

upwards because of soil failure occurring right under the footing

that would have formed a failure surface because of different

levels of soil movement. It is worth noting that this mechanism

and pattern in the ground deformation is well documented in a

bearing capacity test (Das 2007).

The ground deformation captured with LVDTs is on the

same page of the displacement field suggested by the PIV

system, as shown in Figure 10. For the natural ground, the PIV

displacement vector (Figure 10b) was pointing upwards near the

ground surface, but at the same locations, the downward

displacement vectors (Figures 10a) were observed as the ground

was reinforced by geocell.

It is worth noting that the

displacement fields of the reinforced ground are relatively

random compared to the natural ground, which should result

from the fact that the surface processed by PIV is neither a

completely reinforced soil nor a completely un-reinforced soil,

as the boundary condition of the geocell structure shown in

Figures 3 and 4.

4 CONCLUSIONS

This paper summarized the experimental work of using geocell

in ground improvement under an intense rainfall condition,

which recently recurs with an increasing rate owing to climate

change and extreme weather. The result shows that the

installation of geocell can indeed effectively improve the

bearing capacity of the loose-to-moderate ground subject to

high water content as a result of intense rainfall. The increased

bearing capacity should possibly result from the

“equivalent

Tension crack

Tension crack

Tension crack

Footing

(a)

(b)

(a)

(b)