978

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Some properties of the clay and the chemical composition

of the clay and cement used here are summarized in Table 1 and

Table 2, respectively.

Table 1. Physical properties of the bentonite clay

Parameter

Value

Liquid limit

541.9

Plastic limit

67.0

Plasticity index

474.9

Swell index (ml/2g)

34

Cation exchange capacity (meq/100g)

73

Table 2. Chemical composition of the blast furnace slag cement & clay

Main component

Cement

Bentonite

SiO

2

(%)

29.3

53.7

Al

2

O

3

(%)

8.8

23.4

Fe

2

O

3

(%)

1.2

5.9

MgO (%)

6.7

2.4

CaO (%)

47.1

1.9

Na

2

O (%)

0.2

2.2

The prepared samples consist of 80% water, 16% cement

and 4% bentonite (by weight). This composition is in agreement

with other studies in the literature (e.g. Ryan and Day 1986,

Jefferis 1992, Opdyke and Evans 1995). First, a slurry of

bentonite and water was mixed with a high-speed shear mixer

for 5 minutes. The slurry was poured in a closed container and

allowed to hydrate for about 24 hours. Subsequently, a slurry

cement and water (accounted for in the final composition) was

prepared to obtain a water cement ratio of about 0.5. Finally, the

cement slurry and the 24-hour hydrated bentonite slurry were

mixed in a dough mixer for about 10 minutes.

Then the fresh CB slurry was poured in stainless-steel

moulds to prepare cylindrical specimens. The moulds were

lightly vibrated to ensure that any trapped air bubbles were

removed. The bottom and top ends of the mould were sealed

with plastic foil to prevent moisture loss. Then, the samples

were allowed to cure for 7 days in a conditioned room at 18°C.

After that period, when the samples showed enough strength to

be handled, their ends were flattened with a spatula and they

were carefully extruded out of the moulds. Samples with a

diameter of 100 mm and a height of 60 mm were used for

hydraulic conductivity tests.

3 METHODS

The hydraulic conductivity and small-strain shear modulus of a

CB sample were studied in a flexible-wall hydraulic

conductivity cell provided with bender elements. In parallel, the

hardening of the CB mix in contact with water was monitored

through bender element testing in a bench top setup to provide a

reference of

G

0

increase under normal curing conditions.

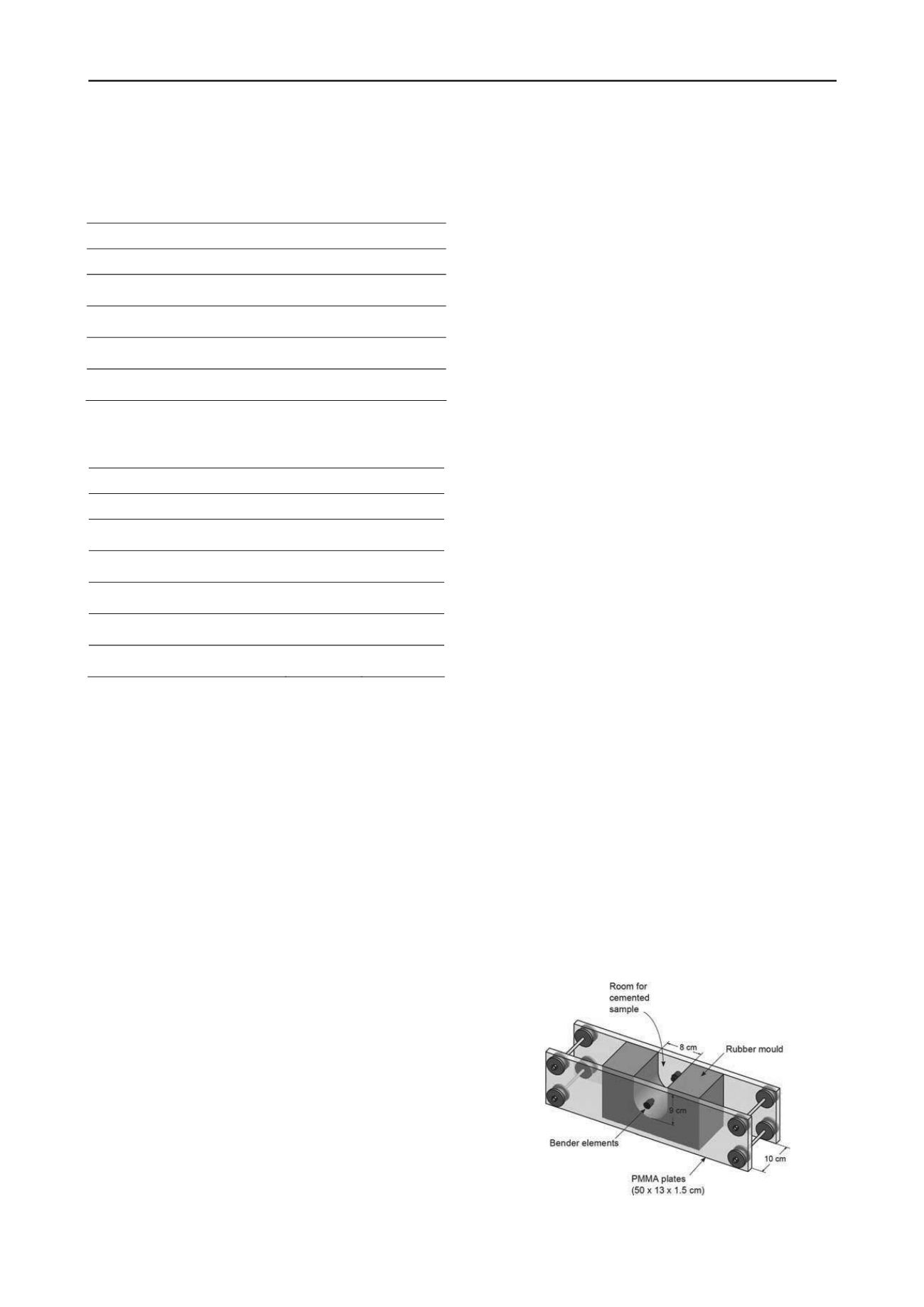

3.1 Bench top bender element test

The small-strain shear modulus of the CB mix was evaluated

(starting from a fresh state) by bender element testing (Shirley

and Hampton 1978, Dyvik and Madshus 1985) in a bench top

setup (Fig. 1). The bender elements used here are of the type

T220-A4–203Y (Piezo Systems, Inc.). The effective bender

element length penetrating in the sample was about 4.5 mm.

The bench top bender element setup consists of two

translucent polymethyl methacrylate (PMMA) plates that hold a

U-shaped rubber mould with an open space for housing a

cemented sample. The bender element transmitter and receiver

are fixed to the PMMA plates, one in front of the other and

vertically aligned. All parts are held together by four sets of

screws and nuts resting on rubber disks to avoid wave

propagation through the apparatus itself. More details on this

setup are given by Verastegui-Flores et al. (2010).

Testing was started immediately after a fresh CB mix was

prepared. The mix was poured into the rubber mould and it was

allowed to cure in a conditioned room at constant temperature

(18°C). In order to avoid desiccation, the sample was kept all

the time under a thin layer of purified water. Bender element

measurements were performed on a regular basis from the first

day of curing up to 2 months approximately.

In bender element testing,

G

0

is determined out of the

propagation velocity (

V

s

) of shear waves generated and detected

by the transmitter and receiver bender elements installed on

opposite sides of a sample.

G

0

is estimated as:

G

0

=

V

s

2

(1)

where

is the density of the sample.

V

s

is evaluated as follows:

V

s

= L / t

s

(2)

where

L

is the tip-to-tip distance between the transmitter and

receiver bender elements, and

t

s

is the travel time of the shear

waves from the transmitter to the receiver.

t

s

is evaluated out of

the signal recordings. In this research,

t

s

was evaluated by

means of two methods. The first one consists of visually

identifying the first direct arrival from the output signal (e.g.

Dyvik and Madshus 1985, Jovičić et al. 1996; Viggiani and

Atkinson 1995). Clearly, the success of this method depends on

the quality of the recorded signal. The second method used here

was the cross-correlation method, first introduced by Viggiani

and Atkinson (1995). The cross-correlation analysis measures

the level of correspondence or interrelationship between two

signals of similar nature and it produces the time shift between

them, which is equivalent to the travel time of the shear wave.

Although some authors argue that the cross-correlation method

may not be suitable for bender element interpretation (e.g.

Arulnathan et al. 1998), it produced very consistent results.

Both methods produced a similar outcome.

Figure 1. Bench top bender element setup