993

Technical Committee 105 /

Comité technique 105

3 PAPERS PRESENTED TO THIS SESSION

3.1

Looking inside a soil sample using x-ray tomography

X-ray computed tomography (CT) is now widely used in

material sciences and has amply proved its interest in

geomechanics (see Viggiani & Hall 2012 for an overview). The

principle of CT measurement consists of recording x-ray

radiographs of a specimen at many different angular positions

around the object. From these different projections, a three

dimensional image of the object can be reconstructed with

appropriate algorithms. X-ray CT is therefore a non-destructive

imaging technique that allows quantification of internal features

of a soil (or rock) sample in 3D.

Otani et al. (2013)

used x-ray CT for imaging a sandy soil at

different levels of compaction in 1D conditions. The motivation

for this experimental study is to check whether the current

criteria for quality control of dynamic compaction of soil for

riverbanks are appropriate or not. Two cases were investigated,

corresponding to a different number of blows to yield the same

total compacting energy (cases 1 and 2 in Fig. 1, corresponding

to higher and lower individual blow energy, respectively).

Quantitative analysis of the 3D images from x-ray tomography

allows Otani and coworkers to obtain the distribution of

porosity in the sample and to follow its evolution with

increasing compaction – see Fig. 1.

Figure 1. Spatial distribution of porosity in two samples of silty sand at

different levels of compaction, as obtained with x-ray CT (

Otani et al.

2013

).

A second experimental study using x-ray tomography is

presented by

Andò et al. (2013)

. Further details and results can

be found in Andò

et al.

(2012a, 2012b). The motivation for this

study comes from the fact that strain localization presents major

challenges for continuum models for geomaterials. For such

models to be successful, the microstructure of the material (for

sand, at the grain scale) should be explicitly taken into account,

in one way or another, which in turn requires experimental

characterization of shear banding at the grain scale.

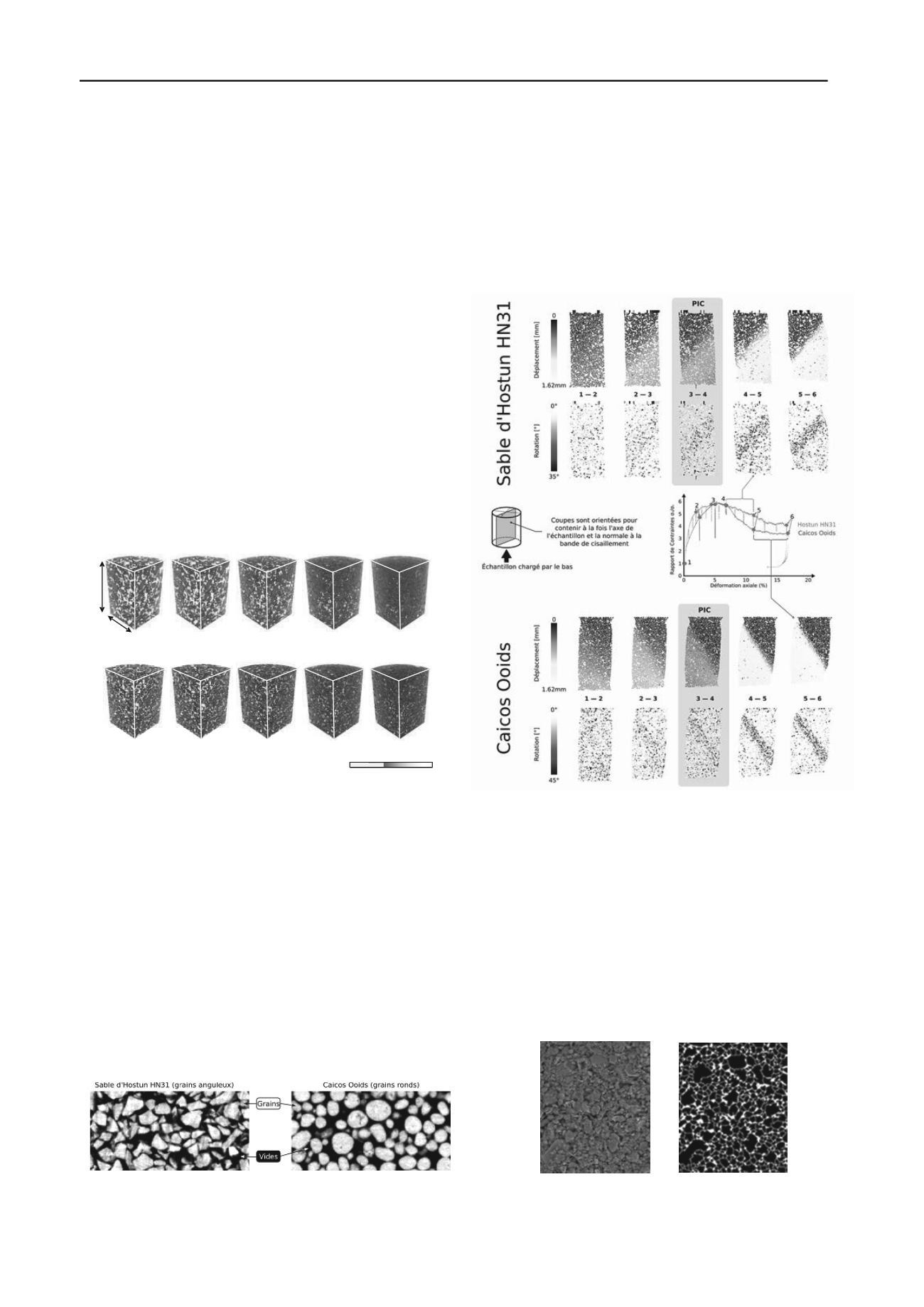

Andò et al.

(2013)

used x-ray tomography to image samples of two

different sands (see Fig. 2) while they deform under triaxial

compression.

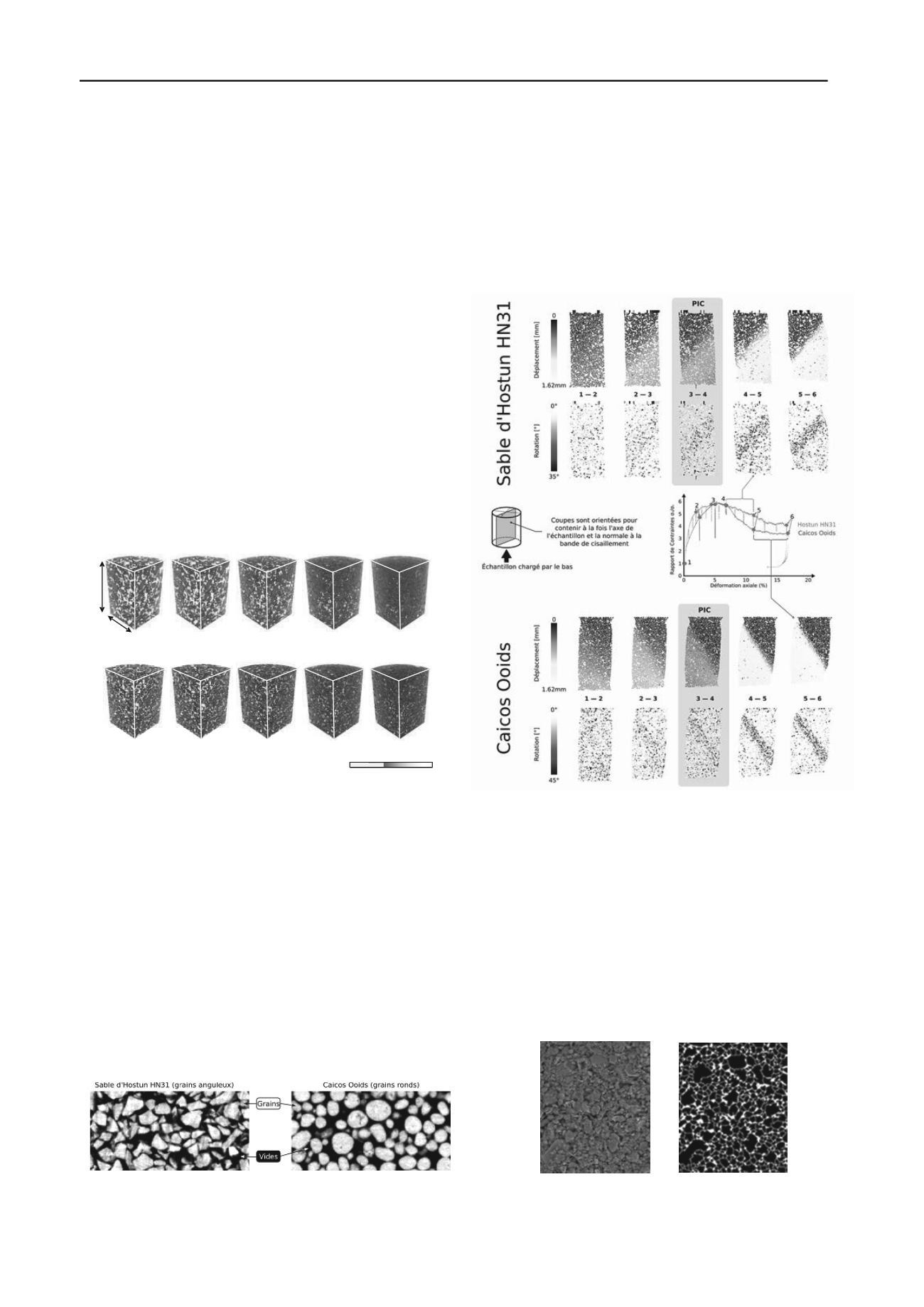

Figure 2. Slices from x-ray images of angular Hostun sand (left) and

rounded Caicos ooids (right) tested by

Andò et al. (2013

).

The results of this study clearly show that thanks to x-ray

tomography, combined with either 3D Digital Image

Correlation or Particle Tracking, the evolution of the 3D

microstructure of a small sample of sand can be followed while

it deforms, individual grains can be distinguished in the time-

lapse 3D images, and analyzed to give the full 3D kinematics

(displacement + rotation) of each individual grain in the sample

(see as an example Fig. 3). Analysis of deformation at this scale

is, in the Authors’ own words, a dream that has come through!

0

80

24

CT-value

initial

Level A

Level C

Level E

Level G

0

40mm

25mm

(a) Case-1

(b) Case-2

initial

Level A

Level C

Level E

Level G

Figure 3. Slices showing grains of a triaxial test on Hostun sand (top)

and Caicos ooids (bottom) at 100 kPa confinement, colored by their

vertical displacement and intensity of 3D rotation. The increments

studied are highlighted on the stress-ratio

vs.

axial shortening in the

middle of the figure (

Andò et al. 2013

).

3.2

Fine-grained soils from micro to macro

Yigit et al. (2013)

present a contribution investigating the time

dependent behavior of clays. In this experimental study, ESEM

micrographs of kaolinite clay are taken under different levels of

load in oedometric compression, and after different amounts of

creep time. The pixel size in the micrographs was 8.47

10

-2

m,

which is small enough to see the macro voids (see Fig. 4).

Figure 4. Raw (left) and segmented (right) ESEM micrographs of

kaolinite clay (

Yigit & Cinicioglu 2013

).