1016

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Figs. 1(b) to (d) illustrate how this model responds to the

normal contact force

F

n

, the shear contact force

F

s

, and the

contact moment

M

. These contact forces can be computed as:

] ,

min[

nb nn

n

RuK F

(2a)

]

(2b)

,

min[

sb s s

s

RuK F

] ,

min[

rb

m

R K M

(2c)

where min[•] is the operator taking the minimum value;

u

n

,

u

s

and

are the overlap, relative shear displacement, and relative

rotation angle;

K

n

,

K

s

and

K

m

=

K

n

R

/12 are the normal,

tangential and rolling contact stiffness;

R

nb

,

R

sb

, and

R

rb

are the

normal, shear and rolling bond strength.

For simplicity, the inter-particle rolling resistance is ignored

at contacts with broken bonds or without bonds. At these

contacts, the linear contact law applies:

n n

n

uK F

(3a)

] ,

min[

n

s s

s

F uK F

(3b)

where

is the inter-particle friction coefficient;

K’

n

and

K’

s

are

the post-failure normal and tangential contact stiffness.

soil grain

tension

(d)

(c)

(b)

(a)

M

u

s

F

s

F

n

u

n

R

rb

Residual

strength

soil grain hydrate

B

R

nb

1

K

n

K

n

1

R

sb

1

K

s

Residual

moment

1

K

r

compression

R

1

R

2

t

Figure 1. Schematic illustration of (a) MH bonded soil grains and its

response: (b)

F

s

against

u

n

; (c)

F

s

against

u

s

;

and (d)

M

against

Jiang et al. (2012a, 2012b) performed microscopic contact

mechanical test to calibrate the model parameters for a large

number of aluminous rod pairs (with a diameter of 12 mm and a

length of 50 mm) bonded by epoxy and cement. Their study

resulted in a generic criterion for bond failure, forming a

strength envelope in a three-dimensional space with axes being

F

n

,

F

s

, and

M

. The projection of the envelope in

F

s

-

M

plane can

be approximated as an ellipse as the following:

1

2

2

2

2

s

rb

sb

R

M

R

F

(4)

The ellipse varies in size with increasing

F

n

. That is,

R

sb

and

R

rb

are functions of

F

n

. For the case of thick bonds, they can be

computed as follows based on experimental findings if only

normal forces are applied on the bond:

n

t

n

n

c

t

n

s

s

sb

R F F R R F L f

R

)]

/()

[( )

(

m

(5a)

t

n

n

c

t

n

r

r

rb

R F F R R F L f

R

)]

/()

[( )

(

(5b)

where

R

t

and

R

c

are the bond tension and compression strength,

respectively, which can be obtained from tension/compression

test of the cementation materials.

L

s

and

L

r

are the slopes of the

straight line linking

R

t

to the peak shear strength or peak rolling

resistance on the projection plane.

f

s

,

f

r

,

n

and

m

are fitting

parameters to the experimental data. They can be calibrated

from contact mechanical tests as Jiang et al. (2012a, 2012b) did

recently. Fig. 2 illustrates their test results with a comparison to

the prediction by Eq. (5).

Since MH remains stable in very extreme conditions, it is

still a challenge to directly measure the strength parameters for

hydrate bonds. Thus, in addition to test data from similar bond

materials, assumptions are necessary for indirectly determining

model parameters for MH bonds. This will be explained later.

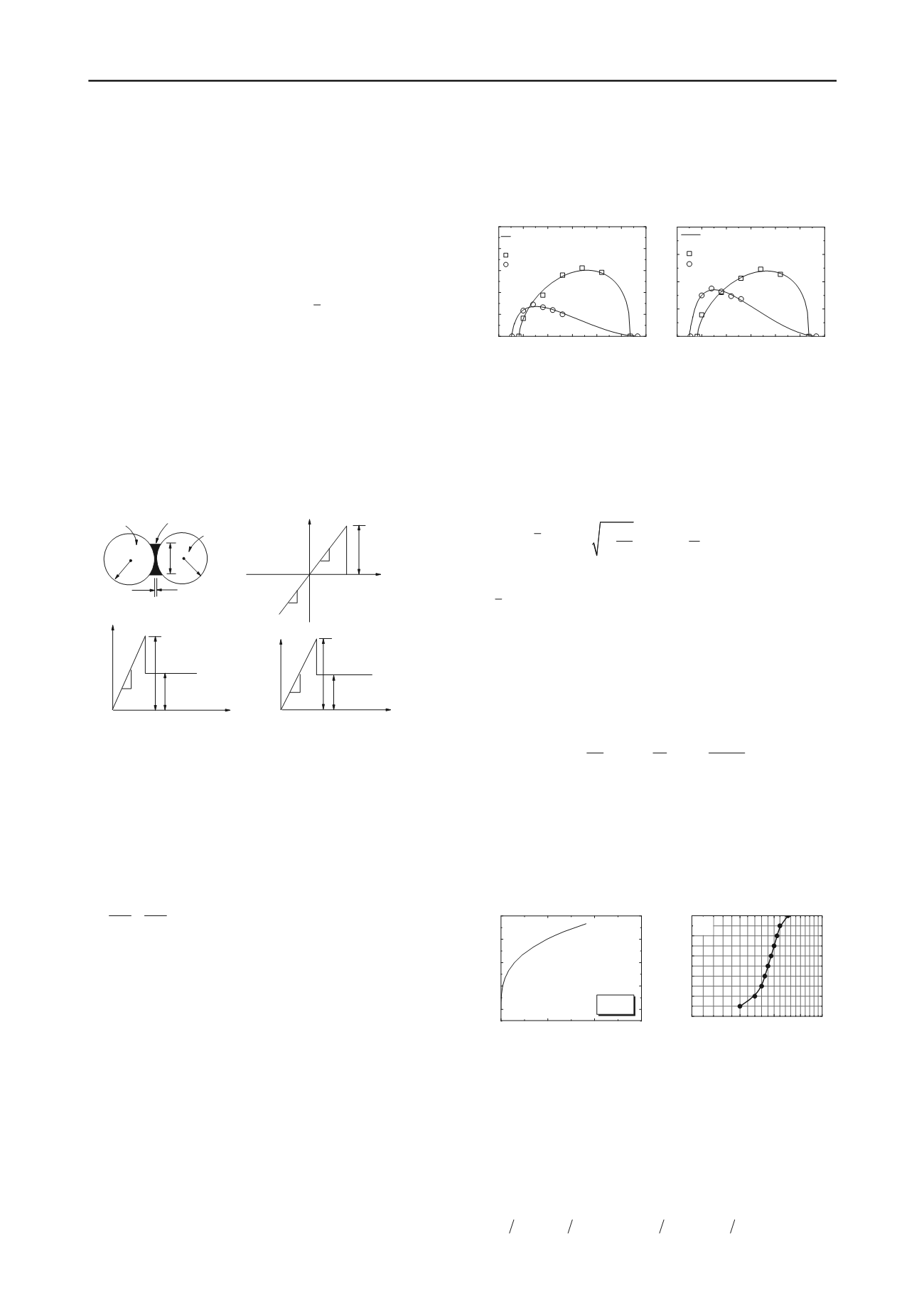

-5 0 5 10 15 20 25

0

3

6

9

12

15

Eq. 5a

Test data

(Jiang et al. 2012a,b)

Cement-bonded

Epoxy-bonded

R

rb

(kN

·

m)

F

n

(kN)

(a)

-5 0 5 10 15 20 25

0

2

4

6

8

(b)

Eq. 5b

R

rb

(kN

·

m)

F

n

(kN)

Test data (Jiang et al. 2012 a,b)

Cement-bonded

Epoxy-bonded

Figure 2. Bond strength envelopes derived from laboratory data: (a)

strength envelope for

R

sb

; and (b) strength envelope for

R

rb

2.2

Determing

from

hydrate saturation

The parameter

relates to a given value of hydrate saturation

S

H

, which is defined in a two-dimensional context as the ratio of

the area of voids occupied by MH,

A

H

, to the total void area,

A

V

.

The area of voids occupied by the

i

t

h

MH bond is:

2

2

2

1

2arcsin(

4

bi

i

A R

)

2

(6)

where we assume (1) the radii of the two bonded particles equal

to

i

R

(i.e. neglecting the different curvatures of the particles);

and (2) the bond thickness is negligibly small. The total area

occupied by hydrate bonds,

A

b

, can be found by summation

over all the bonds. Saturation attributed to pore-filling and

bonding hydrates are denoted as

S

Hb

and

S

Hp

, respectively.

S

Hp

,

generally equal to 20-30% (Masui et al. 2005), can be regarded

as the threshold value of hydrate saturation at which MHs start

to bond sand grains. Accordingly,

1

(1 )

(1 )

m

p

b

H

H Hb

Hp

p

Hp

bi

Hp

i

V

e

A

A

S S S

e

S

A S

A

A

A

(7)

where

m

is the total number of bonds;

A

is the total area of a

cross section of the sample;

e

p

is the planar void ratio. Eq. (7)

provides a non-linear relationship which depends on the state of

compaction of the sample (e.g. relative density) which rules the

particle packing and therefore the value of

m

. Fig. 3(a) shows a

sample curve achieved for the case of a dense soil sample (e.g.,

e

p

= 0.21) consisting particles with diameters ranging from 6 to 9

mm forming a gradation curve as shown in Fig. 3(b).

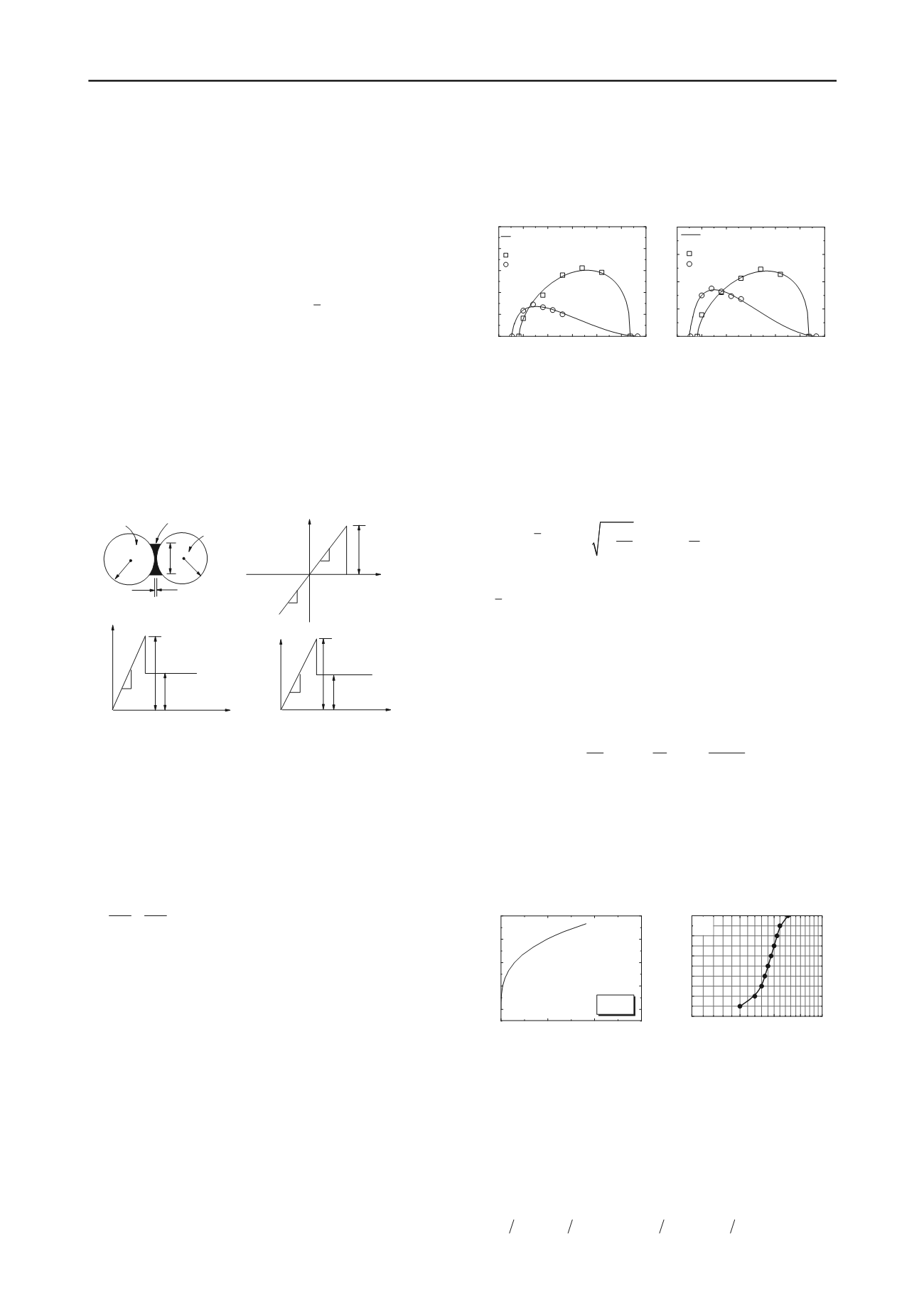

0

10

20

30

0.0

0.3

0.6

0.9

1.2

Parameter

β

nding saturation

S

Bo

4

6

8 10

0

20

40

60

80

100

12

Percentage in mass

smaller than (%)

Particle diameter (mm)

(b)

e

p

=0.21

(a)

H

-

S H0

(%)

Figure 3. (a) Model parameter

at different hydrate saturation for a

dense sample (

e

p

=0.21) with (b) a given gradation curve

2.3

Contact stiffness

Soil grains with the Young’s modulus ranging from 50 to 70

GPa can be regarded as rigid particles relative to MH. Thus, for

MH-bonded grains,

K

n

=

BE

/

t

. The Young’s modulus of MH,

E

,

depends on temperature

T

, confining pressure

p

c

and density

according to the test data (Hyodo et al. 2005). The regression

analysis of these data yields the empirical formula:

0

3

+4950.50

1.98

1821.78

a

c a

w

E p

p p

T T

(8)