1014

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

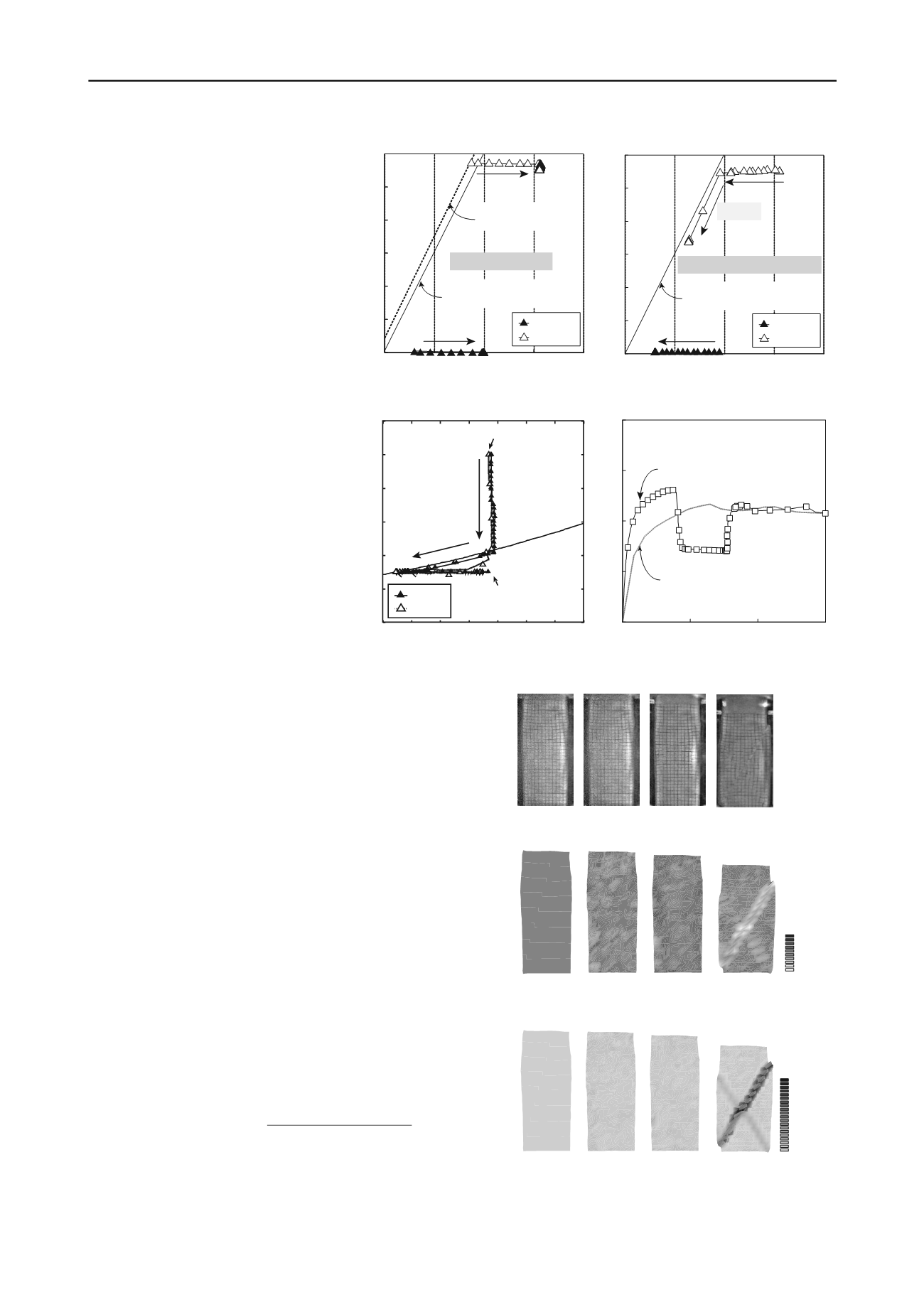

Point (c) corresponds to the point where

MH is dissociated. Point (d) corresponds to

the point where the specimen failed due to

an increase in pore water pressure

(repressurization). Photo 1 shows the

specimen at each axial strain during Figure

12. In Case 2, the specimen failed during

repressurization when the stress path

reached the strength of the host sand. From

the photo, it can be seen that from point (d)

a shear band appeared in the specimen and

failure occurred. Figures 13 and 14 show

the volumetric strain and maximum shear

stress contour obtained during Photo 1.

From point (a) to (c) the specimen was

consolidated and the volume was

compressed. At (d), volumetric dilation

occurred in the shear band and local

deformation was observed clearly.

5 CONCLUSIONS

(1) In drained shear tests on host sands,

initial stiffness and strength decreased with

increasing fines content and there was a

strong trend for contraction of volumetric

strain.

(2) For all specimens, the initial stiffness

and peak strength of those containing MH

increased due to MH`s cementation force,

and volumetric strain behaved in a more

dilative manner. However, both initial

stiffness and strength decreased with

increasing fines content of host sands.

(3) In plane strain shear tests, Tc and

Toyoura sand as host sands with and

without MH were compared. Due to the existence of MH, initial

stiffness and strength increased in both materials, however the

tendency was more apparent in Toyoura sand compared with

Tc.

(4) The local deformations occurred more clearly in Toyoura

sand, compared with fine material. It also appeared more clearly

when the specimen contained MH.

(5)

During depressurization, marked deformation was not

observed, because of an increase of effective stress. However,

after depressurization, repressurization caused the specimen to

fail in the case of high initial shear stress conditions.

6 ACKNOWLEDGEMENTS

The first half of the present work was done as the activity of

Research Consortium for Methane Hydrate Resources in

Japan (MH21 Research Consortium) by the Ministry of

Economy and Industry and the latter half was supported by

KAKENHI 20246080 by the Ministry of Education and Science

in Japan. The authors would like to express their sincere thanks

to their supports.

7 REFERENCES

Hyodo, M., Nakata, Y., Yoshimoto, N. and Yoneda, J. 2008. Shear

strength of methane hydrate bearing sand and its deformation

during dissociation of methane hydrate.

Proc. of 4th Int. Symp. on

Deformation Characteristics of Geomaterials

, 549-556.

MH21 Research Consortium 2012.

/

Yamamoto, K. 2009. Production Techniques for Methane Hydrate

resources and Field Test Programs.

Journal of Geography,

Vol.118,

No. 5, 913-934.

Yoneda, J., Nakata, Y. 2011. Deformation of deep seabed during

dissociation of methane hydrate. Proc.

The 14th Asian Regional

Conference on Soil Mechanics and Geotechnical Engineering.

ISSMGE.

Paper

㻌

ID290.

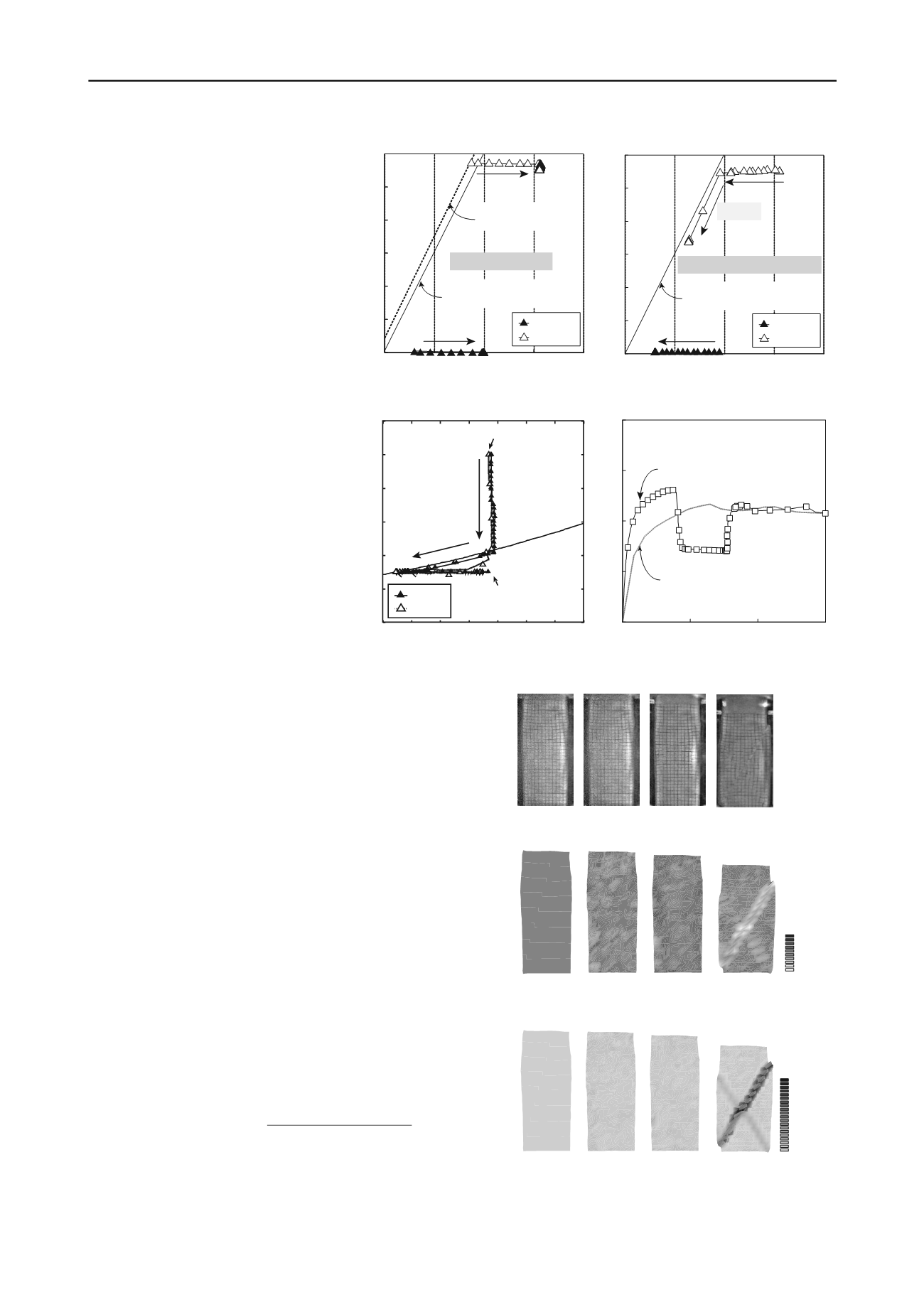

Figure 12 Relationship between stress ratio

and axial strain (Case2)

0.0

0.5

1.0

0

5

10

15

Stress ratio (

'

1

-

'

3

)/(

'

1

+

'

3

)

Axial strain

a

(%)

Case2

(a)

(c)

(d)

(b)

S

MH

=0.0%

1 2 3 4 5 6 7 8

0

2

4

6

8

10

12

Temperature

T

(

o

C)

Stability boundary

After depressurization

(Water-Methane)

(Methane hydrate)

Initial condition

Case1

Case2

Pore pressure

u

(MPa)

Figure 11 Temperature and pore pressure

path in depressurization test

(a)

a

=3.5%

(b)

a

=4.0% (c)

a

=7.2% (d)

a

=12.7%

Figure 13 Contour of volumetric strain at each axial strain

(Case2)

Figure 14 Contour of maximum shear strain

at each axial strain (Case2)

0

25

50

75

100

(%)

max

Photo 1 The specimen image at each axial strain(Case2)

-25

0

25

(%)

v

(a)

a

=3.5%

(b)

a

=4.0% (c)

a

=7.2% (d)

a

=12.7%

(a)

a

=3.5%

(b)

a

=4.0% (c)

a

=7.2% (d)

a

=12.7%

Figure 10 Stress path in repressurization

test

Figure 9 Stress path in depressurization test

0

1

2

3

4

5

6

0

5

10

15

20

Principal stress difference (

'

1

-

'

3

)/2 (MPa)

Mean principal stress (

'

1

+

'

3

)/2 (MPa)

Case1

Case2

Failure envelope of

MH bearing sand

Failure envelope of

Host sand

Depressurization

0

1

2

3

4

5

6

0

5

10

15

20

Principal stress difference (

'

1

-

'

3

)/2 (MPa)

Mean principal stress (

'

1

+

'

3

)/2 (MPa)

Water pressure recovery

Failure envelope of

Host sand

Failure

Case1

Case2