530

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

4 CONCLUSIONS

Significant advances have been made in the last four

decades in the design, use and interpretation of the results

from penetrometer devices used for subsurface

characterization. Similarly, over the past two decades,

significant new insight has been developed into the role of

surface roughness on the behavior of geotechnical interfaces.

An emerging family of innovative devices has been

developed in the last decade that leverages the advances in

performance of penetrometer devices with the new

understanding of interface behavior to produce multi-sleeve

devices that allow for direct in-situ determination of the

relationship between surface roughness and interface shear

as well as the development of shear induced pore pressures

when surfaces of various roughness are sheared against soils.

A unique aspect of this family of devices is the use of

multiple friction sleeves with surface of different roughness

in the same sounding so that the effects of material

variability can be isolated and/or eliminated. To date, all

these devices rely on response of soils during axial

penetration.

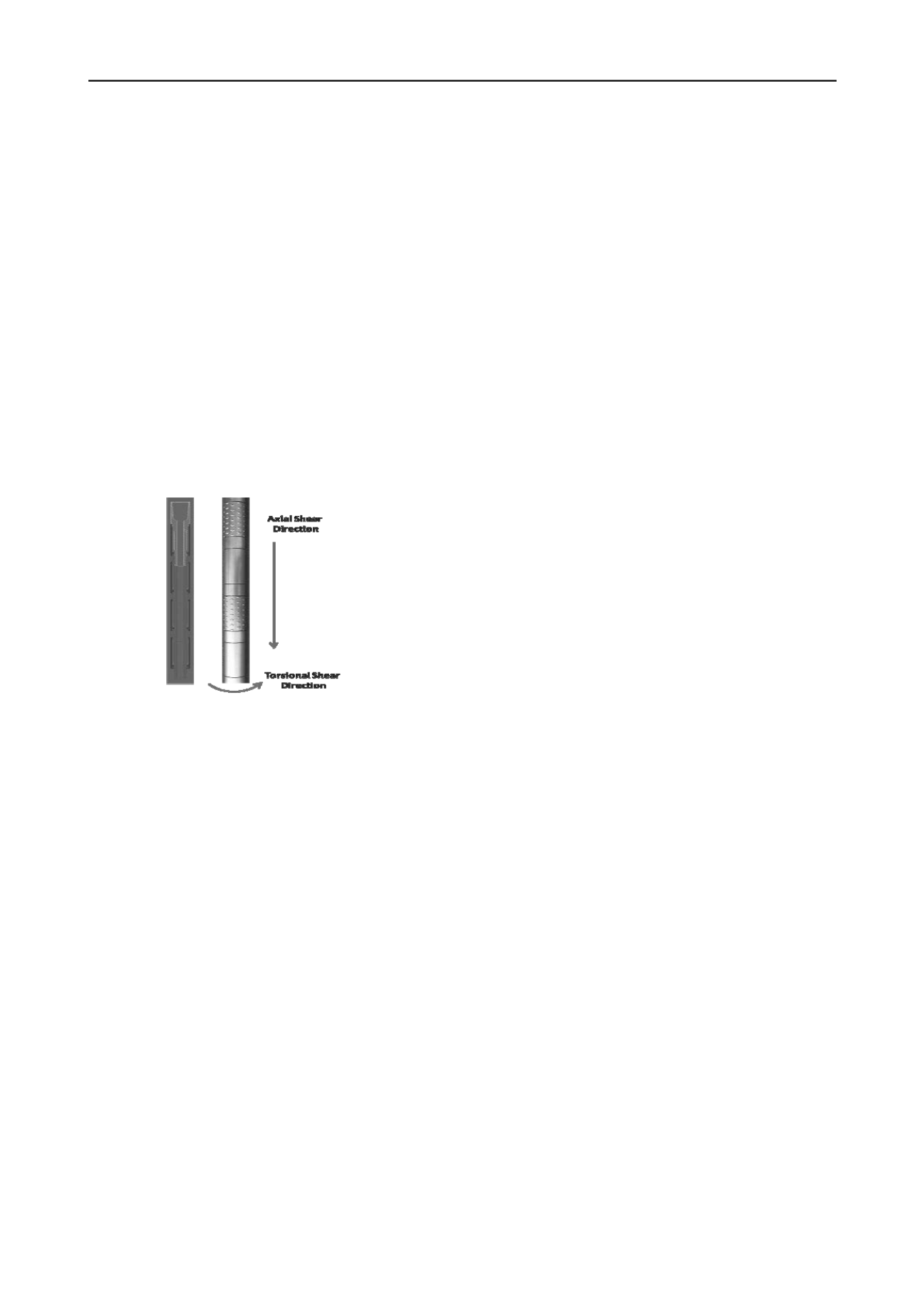

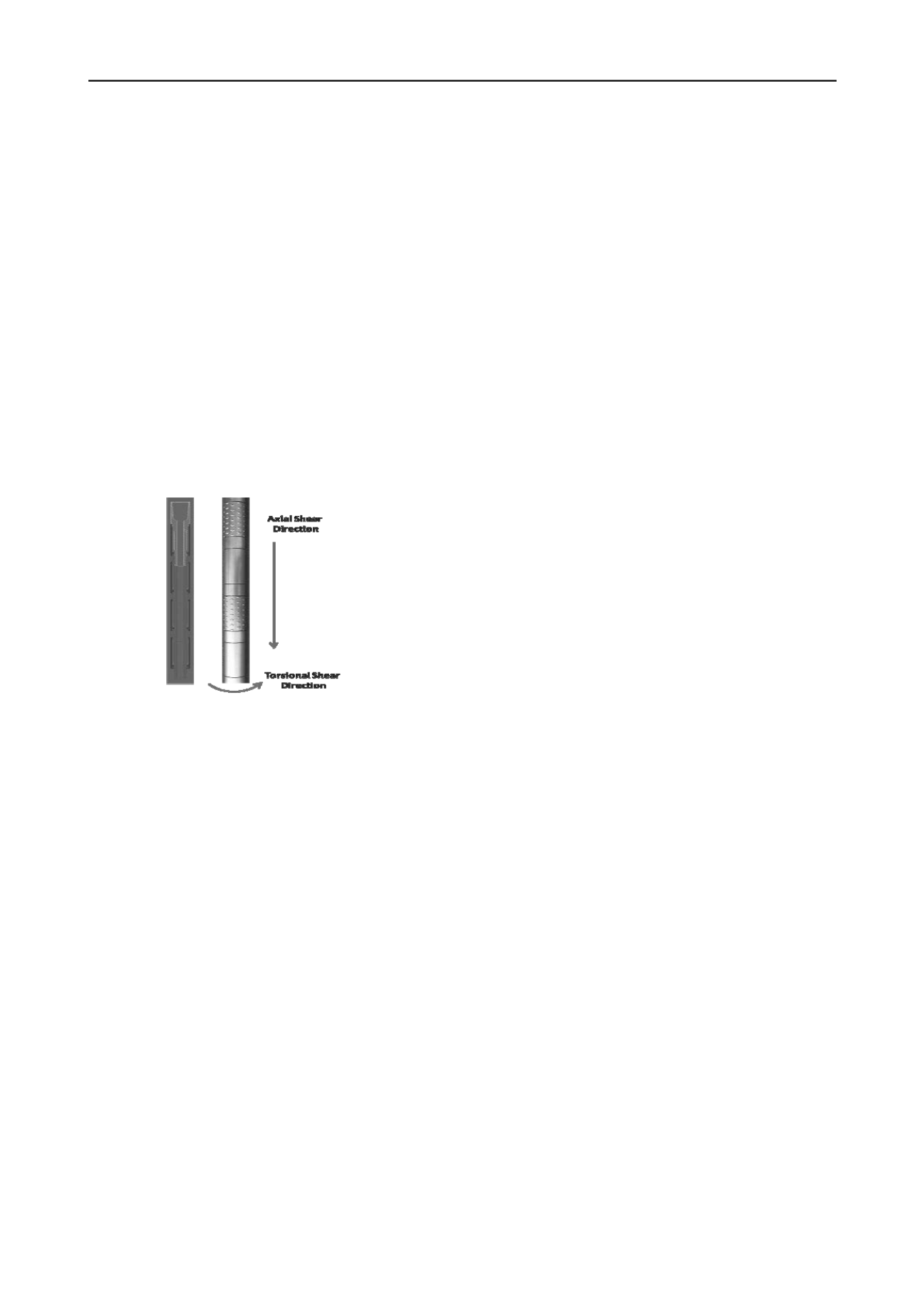

Figure 6. Schematic and photograph of multi-sleeve piezo- friction-

torque penetrometer showing load application modes.

This paper describes the development of a new device that

embodies the attributes of the existing multi-sleeve devices

but incorporates the ability to also conduct torsional friction

penetrometer tests in the same sounding. In contrast to

existing vane shear type devices which involve the

application of a torsional force to a rigid central shaft and

measure the resistance to rotation of a set of blades in a soil,

the new device enables measurement of torsional resistance

with the same textured sleeves used in the axial stage of the

test. This is possible through the use of an innovative

electro-mechanical system that allows independent

measurements of axial and torsional resistance of the sleeves

of the penetrometer device. The availability of

complimentary axial and torsional shear forces along with

the associated pore pressures generated by friction sleeves of

different surface roughness represents a potential “disruptive

technology” in the in-situ characterization of soil properties

ranging from soil type to soil strength and deformation

properties to assessment of the in-situ state of stress and

associated parameters such as the in-situ stress ratio.

Significant opportunities exist for dramatic advances in

subsurface investigation. Single sensor historical precedent

has guided the design and configuration of in-situ devices,

there are clear advantages to developing multiple sensor

systems for future investigation studies.

The recent development of various configurations of multi-

sensor systems including the previously presented

generation 1 MFA and generation 2 MPFA as well as the

proposed generation 3 MPFTA device introduced herein

represent a significant departure from traditional practice.

Amongst the benefits of the latter device are:

i) Up to sixteen independent measures of interface shear

ranging from smooth surface sliding to textured surface soil

shearing can be realized in a single sounding in contrast to

the three measures possible with conventional cone

penetration systems.

ii) The effects of different vertical and horizontal stress

states on measured sleeve stresses can be accounted for by

means of the axial and torsional interface stress response.

iii) The procedure for performing combined axial-torsional-

piezo penetration testing of the subsurface using the

proposed MPFTA system involves a series of steps which

allows them to be readily controlled from a remote location

and to be performed using robotic systems.

5 ACKNOWLEDGEMENTS

The initial device development reported herein was funded

in part by a grant from the US National Science Foundation

to the Georgia Tech Research Corporation under Contract #

CMS 9978630.

6 REFERENCES

Chandler, R.J. (1998). “The in-situ measurements of the undrained

shear strength using the field vane”,

Vane Shear Strength

Testing in Soils. Field and Laboratory Studies

. A.F. Richards

(ed.), ASTM STP 1014, ASTM, Philadelphia, pp. 13-44.

DeJong, J.T. (2001). “Investigation of Particulate-Continuum

Interface Mechanics and Their Assessment Through a Multi-

Friction Sleeve Penetrometer Attachment”,

PhD Dissertation,

Georgia Institute of Technology

, Atlanta, May, 360 pp.

DeJong, J.T. and Frost, J.D. (2002). “A Multi-Friction Sleeve

Attachment for the Cone Penetrometer,”

ASTM Geotechnical

Testing Journal,

25, No. 2, pp. 111-127.

DeJong, J.T., Frost, J.D., and Cargill, P.E. (2001). “Effect of

Surface Texturing on CPT Friction Sleeve Measurements.”

Journal of Geotechnical and Geoenvironmental Engineering

,

127, No. 2, pp. 158-168.

Frost, J.D., and DeJong, J.T. (2005) “In Situ Assessment of the Role

of Surface Roughness on Interface Response,”

Journal of

Geotechnical and Geoenvironmental Engineering

, 131, No. 4,

pp. 498-511.

Frost, J.D., Hebeler, G.L., and Martinez, A., (2012), “Cyclic Multi-

piezo-friction Sleeve Penetrometer Testing for Liquefaction

Assessment”, Proceedings of 4

th

International Conference

(ISC’4)

on

Geotechnical

and

Geophysical

Site

Characterization, Pernambuco, Brazil, Vol. 1, pp. 629-636.

Hebeler, G.L. (2005). “Multi Scale Investigations of Interface

Behavior

.

”

PhD Dissertation

. Georgia Institute of Technology,

Atlanta, August, 772 pp.

Hebeler, G.L., and Frost, J.D., (2006), “A Multi Piezo-Friction

Attachment for Penetration Testing”,

Proceedings of ASCE

Geo-Institute Congress: Geotechnical Engineering in the

Information Technology Age

, Atlanta, CD ROM.

Uesugi, M. and Kishida, H., (1986) “Frictional Resistance at Yield

Between Dry Sand and Mild Steel.”

Soils and Foundations

,

Vol. 26, No. 4, pp. 139-149.