521

Technical Committee 102 /

Comité technique 102

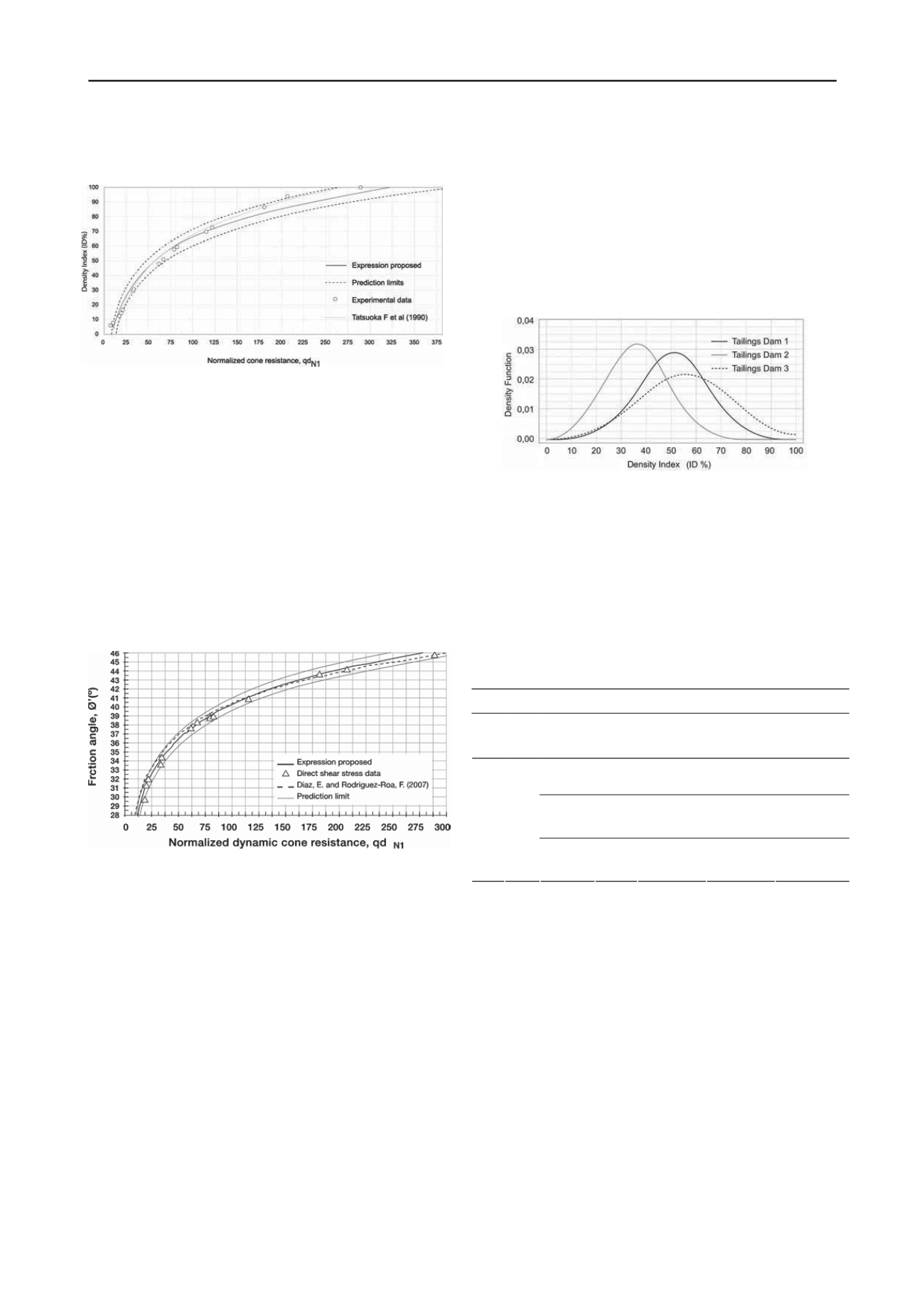

Figure 2 shows that the results of the model are very close

to the experimental results. In addition, the relation proposed by

Tatsuoka et al. (1990) was used by replacing qc

N1

by qd

N1

.

Figure 2. The experimental points, relations proposed and references for

estimating the ID% of mine tailings as a function of qd

N1

.

1.3.2

Relation

’ = f (qd

N1

)

Since we considered that mine tailings can be globally classified

within one geotechnical class, it is possible to estimate

’ as a

function of the resistance of qd

N1

by a single relation. To do

this, a regression analysis was performed on all the pairs of

experimental data (qd

N1

,

’) obtained during the calibration

tests, for the three samples of mine tailings (figure 3). The

model used is given by the following equation:

N1

qd ln 5.54

14.79

'

with

10.0 ≤ qd

N1

≤ 280.0

(3)

As it can be seen on figure 3, the results of the model are

very close to the experimental results. In addition, the relation

proposed by Díaz and Rodríguez-Roa (2007) was used by

replacing qc

N1

by qd

N1

.

Figure 3. Experimental points, proposed and bibliographic relations for

estimating

’ of mine tailings as a function of the qd

N1

.

This result is in full agreement with the works already

carried out on the correlation between qc and qd obtained with a

Panda penetrometer. Indeed, it has been proven (Chaigneau et

al. 2000, Lepetit 2002) that in the case of sands and silty sands,

the average value obtained for the ratio qd/qc is equal to 1.03.

More recent research performed by Rahim et al. (2004)

confirmed the relation between qd and qc. Their results obtained

for granular soils have been demonstrated experimentally and

analytically on the basis of the cylindrical cavity expansion

theory and that of cavitation collapse.

The resistance qd obtained with a light Panda penetrometer

can therefore be assimilated with qc. In conclusion, in the case

of mine tailings:

(1) density index (ID%) and effective friction angle (

’) can

be deduced very precisely from the normalised cone penetration

resistance qd

N1

by a two single relations,

(2) relation qd

N1

= qc

N1

is very well validated which allows

using either static or dynamic penetrometers according to need.

1.4

Application case: density index (ID%) and associated

mechanical behavior

On the basis of equation 2, it is possible to estimate the

profiles of the density index (ID%) as a function of depth from

the penetrometric tests performed in situ. The adaptation of the

correlation presented in table 2, allows estimating the

mechanical behaviour of mine tailings as a function of ID%. At

global scale (measurements processed at the scale of the tailings

dam by using the ID% distribution obtained from all the

penetration tests performed), the distribution of all these ID%

values for each dam can be adjusted by a normal law (Figure 4).

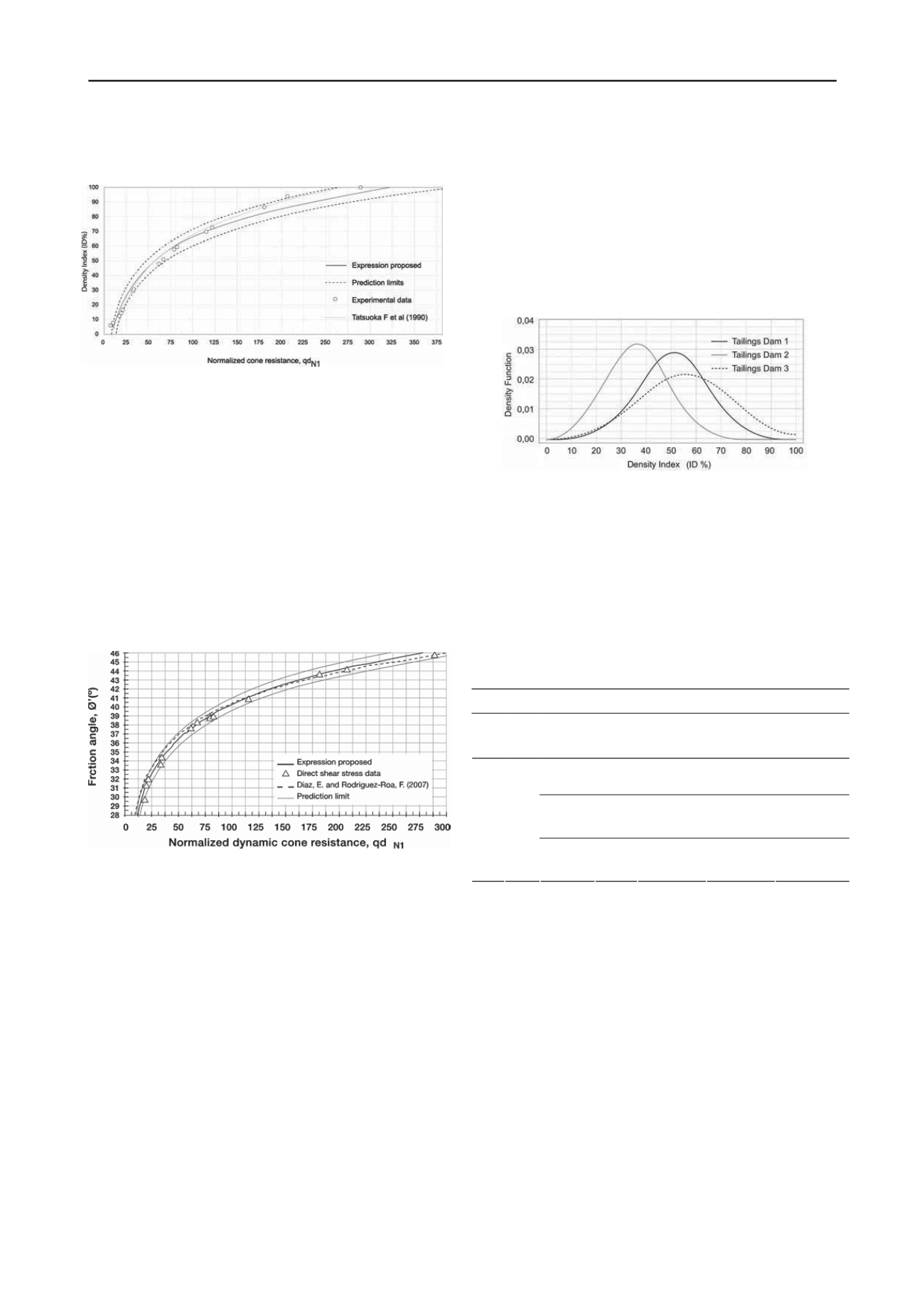

Figure 4. Density function of ID%. Proposed relation for tailings dams

No. 1, No. 2 and No. 3 in the study.

At global scale, the density function makes it possible to

obtain a global idea of the mechanical behaviour of the mine

tailings stored, by considering the limit value of ID%, which

permits classifying contractant or dilatant behaviour and

associate in a qualitative way the liquefaction potential. As an

example, table 3 presents a probabilistic analysis in global scale

of the variability of ID% and the mechanical behaviour for the

tailing dam

No.1

.

Table 3. Density index (ID%) and associated mechanical behaviour.

nalysis at global scale. Tailings dam No. 1.

A

ID%

Analysis of the mechanical behavior

Av.

C.V

%

ID% % of

values

State of

compaction

Mechanical

behaviour

Liquefaction

potential

< 55

58

Low

Contractant

High

55 – 60

13

Average

density

Contractant

/Limit

Limit

52 28.3

60 – 100 29

Dense to

very dense

Dilatant

Null

At a local scale (measurements processed at the scale of

each penetration test, by using the ID% distribution), the

distribution of all these ID% values can then also be adjusted by

a normal law (figures 5a, 5b). The so-obtained results are

consistent with the compaction test performed during the

construction of the three tailings dams.

The results are similar for the three dams, they show that a

local test can be used to estimate ID% for each penetration test,

with sufficient precision provided that the calibration tests have

been carried out on the material characteristics of the dam at the

scale of the structure concerned. The variability of ID% and the

soil mechanical behaviour associated, allows to estimate in a

first stage, the liquefaction potential of tailings dams in both

scales, global and local, and identify in a local scale the zones

with lower strengths through a layer by layer penetration test

(Figure 6).

The evaluation of the risk of liquefaction has been

expressed in an equation formulated by Seed and Idriss (1981).

The classical method compares locally the ratio of the cyclic

resistance of the soil (CRR) with the ratio of the cyclic shearing

stress ratio (CSR) stemming from seismic stress. The notion of

liquefaction potential is therefore linked to the fact that ratio