520

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

parameters. To do this, we propose an estimation method based

on measuring the dynamic cone resistance (qd) that can be

relatively easily measured on this type of structure.

1.2

Normalisation of qd

Estimating ID% and

’ by using empirical and semi-empirical

relations, first implies normalising qd at a reference stress

corresponding to atmospheric pressure (pa), using the following

equation 1.

q

1N

Cqd

qd

with

c ' v a

q

p C

(1)

where: qd

N1

is the dimensionless normalised dynamic cone

resistance, qd is the dynamic cone resistance, pa is the

atmospheric pressure,

’

v

is the effective vertical stress, “c” is

the normalisation coefficient (0.5 to 0.75).

According to Moss et al. (2006), this reference stress value is

considered as reasonable if the depth/stress relation is taken into

account. According to Salgado et al. (1997) and Moss et al.

(2006), the normalisation coefficient is not only linked to the

intrinsic properties of the soil such as the type of grain and the

physical characteristics of the material (mineralogy,

granulometry, particle shape and texture characteristics), lateral

pressure (K

o

), compressibility, cementation, resistance to

crushing of the particles, etc.

1.3

Experimental approach

Our study is based on the use of cone penetration resistances

(qd) obtained by using the Panda test. The Panda device is a

manual light dynamic penetrometer with variable energy and a

small cone section (2.0 or 4.0 cm

2

) (Gourvès et al. 1997, Benz

2009). The Panda provides the cone resistance qd of the soil as

a function of depth, and is capable of performing a large number

of in situ tests thanks to its small size and its quick

implementation. This device can operate until 6.0 (m) in depth

and for materials having particles size lower than 50.0 (mm).

Table 1. Geotechnical properties of mine tailings. Values and statistical

nalyses of experimental data from three representative tailings dams.

a

No. 1

No. 2

No. 3

Geo.

Prop

Av.

CV

Av.

CV

Av.

CV

s

3.09

4.6

3.36

8.0

3.1

2.2

D

50

0.13

19.0

0.11

15.2

0.25

8.7

F.C

28.0

28.7

33

26.3

17

10.0

IP

0

0

0

0

0

0

dmax

18.2

6.2

20.8

8.0

18.5

2.3

d

17.5

6.6

20.1

8.2

18.1

2.9

w

nat

11.0

22.3

3.3

43.1

7.5

27.3

qd

4.8

50.6

2.87

45.9

1.95

52.8

N

60

22

62.5

12

58.8

-

-

s: specific weight (kN/m

3

), D

50

: median diameter (mm), F.C: percentage

of fines less than 80 (µm), IP: plasticity index (%),

dmax: Proctor dry

density (kN/m

3

),

d: dry density in situ (kN/m

3

), w

nat

: water content in-situ

(%), qd: cone resistance PANDA test (Mpa), N

60

: corrected penetration

resistance index, Av: average, CV: coefficient of variation (%).

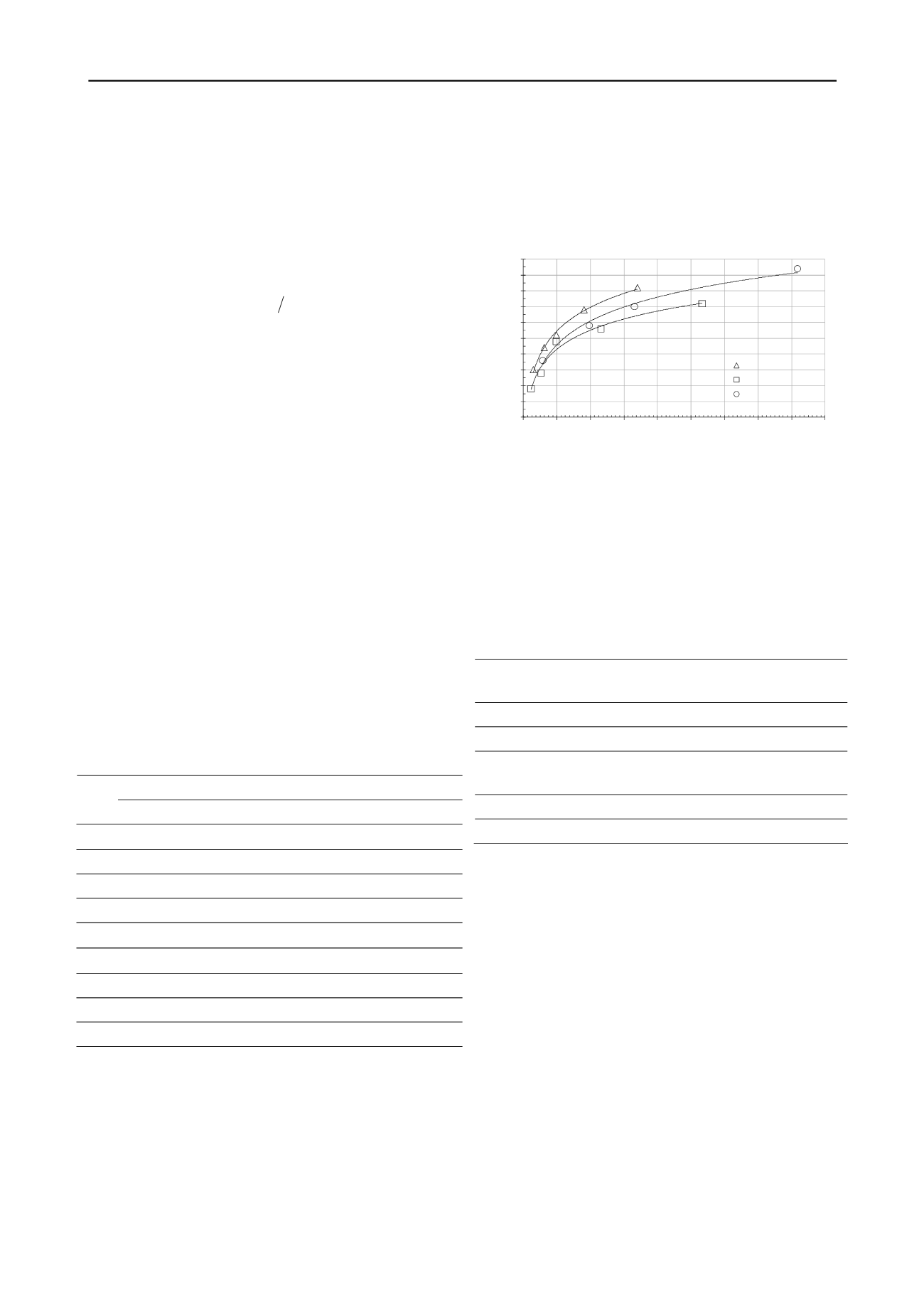

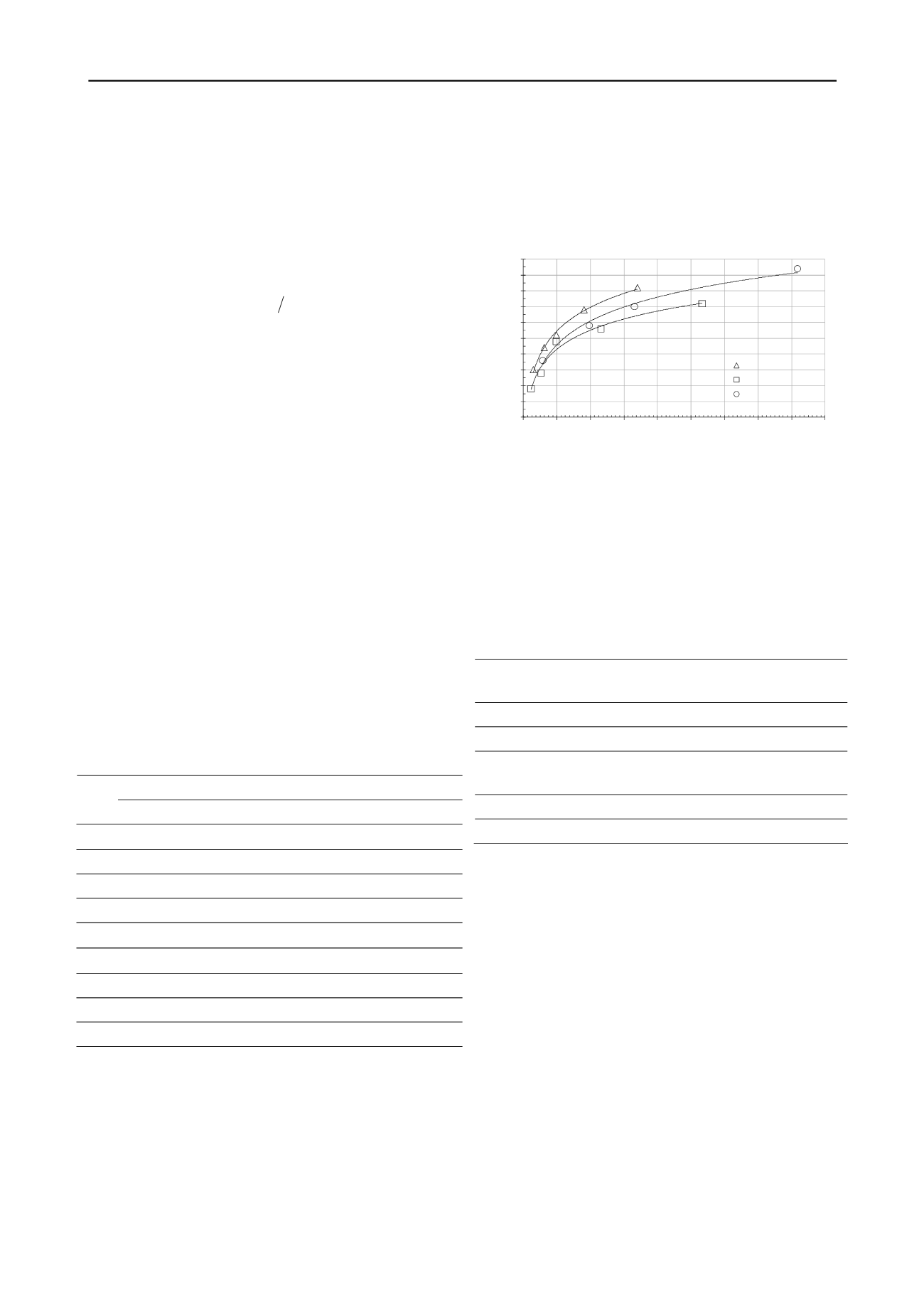

A serie of Panda tests have been performed on the mine

tailings coming from three dams studied, under controlled

laboratory conditions in a calibration chamber. The following

procedure was used:

a) Determination of the physical characteristics of 3 samples of

mine tailings of copper sulphates (Table 1).

b) Performing dynamic cone resistance tests in a calibration

mould for different states of density to obtain the relation

d/qd

(calibration curve). A logarithmic relation can be observed, in

agreement with previous results (Chaigneau et al. 2000) for this

type of material. Figure 1 gives the calibration curves

d/qd

obtained for dams No. 1, No. 2 and No. 3.

c) Normalisation of qd at atmospheric pressure (equation 1).

d = 1,0811ln(qd) + 15,983

R² = 0,9948

d = 0,8693ln(qd) + 15,552

R² = 0,9755

d = 1,086ln(qd) + 15,543

R² = 0,9883

Figure 1. Relation

d/qd for tailings dams No. 1, No. 2 and No. 3 in the

study.

1.3.1

Relation ID% = f (qd

N1

)

The equivalence between the state of density (% Optimum

Proctor Normal) and ID% was estimated for each calibration

test. On the basis of the normalised cone resistance (qd

N1

), and

by considering the classification modified by Skempton (1986)

and adapted by Villavicencio (2009), we estimated ID%

associated with each degree of compaction (table 2).

Table 2. Estimation of the state of compaction and associated

echanical behaviour for silty sands. Villavicencio (2009).

m

qd

N1

ID%

State of

compaction

Mechanical

behaviour

Liquefaction

potential

0 – 17

0 – 15

Very low

Contractant

High

17 – 69

15 – 55

Low

Contractant

High

69 – 82

55 – 60

Average

Contractant

/Limit

Limit

82 – 162

60 – 80

Dense

Dilatant

Null

162 – 326 80 – 100

Very dense

Dilatant

Null

Studies conducted by Troncoso (1986) have concluded that

for mine tailings with a percentage of fines around 15% , with

confining stresses between 50 kPa and 350 kPa, ID% below

50%-60% is an indicator of contractancy. Under this condition,

if the material is saturated or partially saturated, under seismic

conditions, the risk of liquefaction is real. On the other hand,

the material will tend to a dilatant behaviour for a relative

density over these values. Verdugo (1997) have conducted an

analysis of the variation of the minimum and maximum

densities (Vibratory and Proctor compaction) both with mine

tailings and similar soils (sands and silts) with different

percentage of fines. They conclude that in situ ID% of 60% is a

very reasonable compaction value with a satisfactory

mechanical behaviour (dilatancy) in structures that allow certain

degree of deformation such as the tailing dams.

An empirical model was adapted by using a simple

regression on all the pairs of experimental data (qd

N1

, ID%) for

the three samples of mine tailings. Since we consider that mine

tailings can be globally classified in a single geotechnical class,

it is possible to estimate ID% as a function of the resistance

qd

N1

by a single relation. The model used is given by the

following equation:

4.65

ln5.28 %

1

N

qd

ID

with 10.0 ≤ qd

N1

≤ 326.0

(2)

14,0

5

0

5

0

5

0

5

0

5

19,0

0,0 2,0 4,0 6,0 8,0 10,0 12,0 14,0 16,0 18,0

Dry density (KN/m

3

)

Dynamic cone resistance,qd (MPa)

14,

15,

15,

16,

16,

17,

17,

18,

18,

Tailings Dam No 1

Tailings Dam No 2

Tailings Dam No 3