528

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

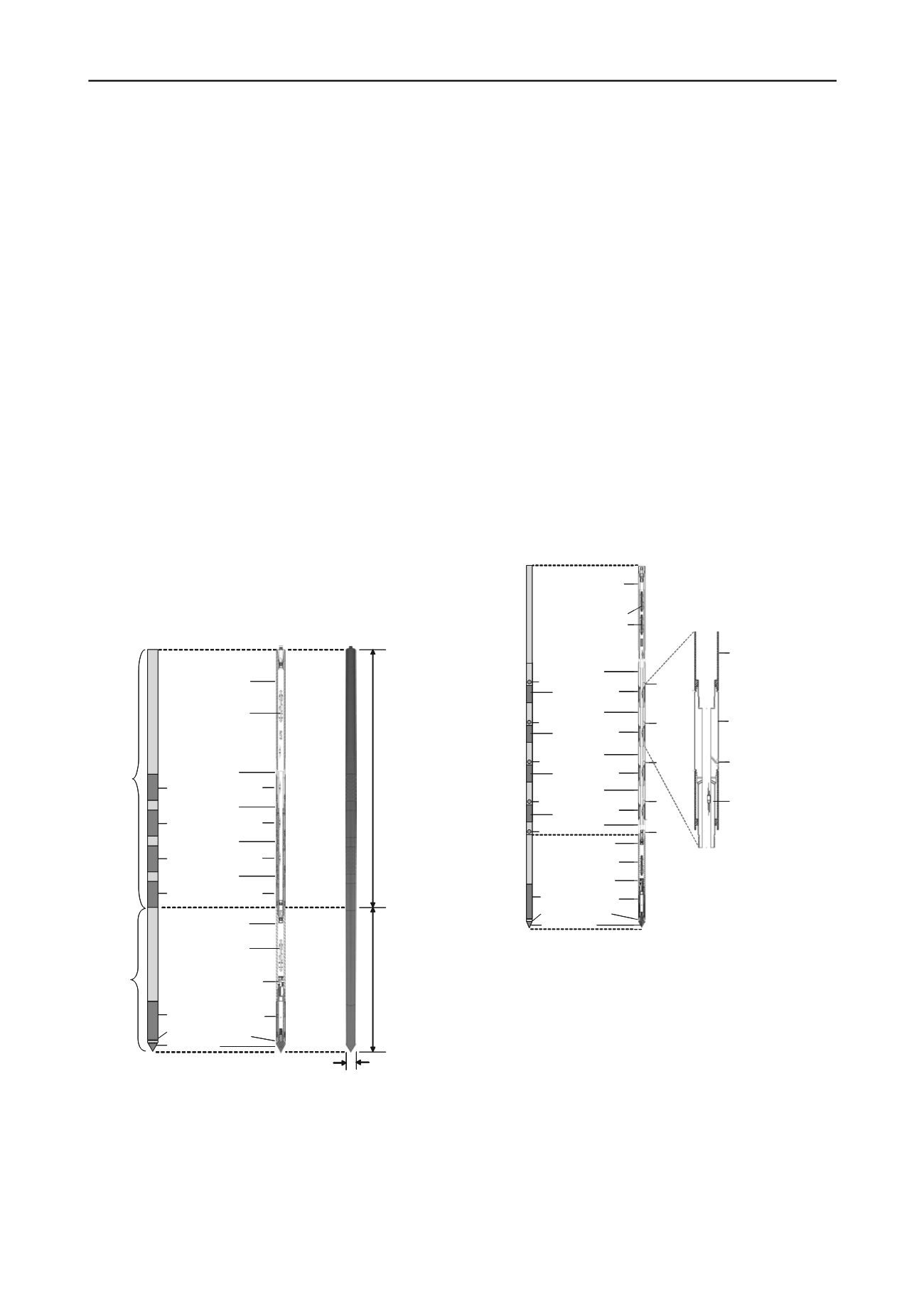

2.1 First Generation: Multi-sleeve Friction Attachment

(MFA).

The first generation of multi sensor attachments

deviates from the standard CPT in that the MFA is capable

of measuring four different friction sleeve stresses in

addition to the standard CPT measurements (q

t

, f

s

, u

2

). Each

sleeve position offers the possibility of being equipped with

a sleeve of different roughness, with the intention of

inducing different degrees of shearing in the soil. Figure 1

shows a schematic of the MFA. According to studies

conducted by Frost and DeJong (2005), the standard smooth

CPT friction sleeve measurement is more indicative of soil

sliding against the sleeve as opposed to shearing against the

soil. The reason is that the conventional CPT friction sleeves

are manufactured with an intentionally smooth surface. As a

consequence of the MFA’s multi-sensor configuration, the

device is able to determine the end bearing capacity of the

soil and the relationship between interface shear strength

resistance and surface texture in a single sounding. The

important relationship between interface shear strength and

surface roughness was originally identified through

laboratory tests by Uesugi and Kishida (1986).

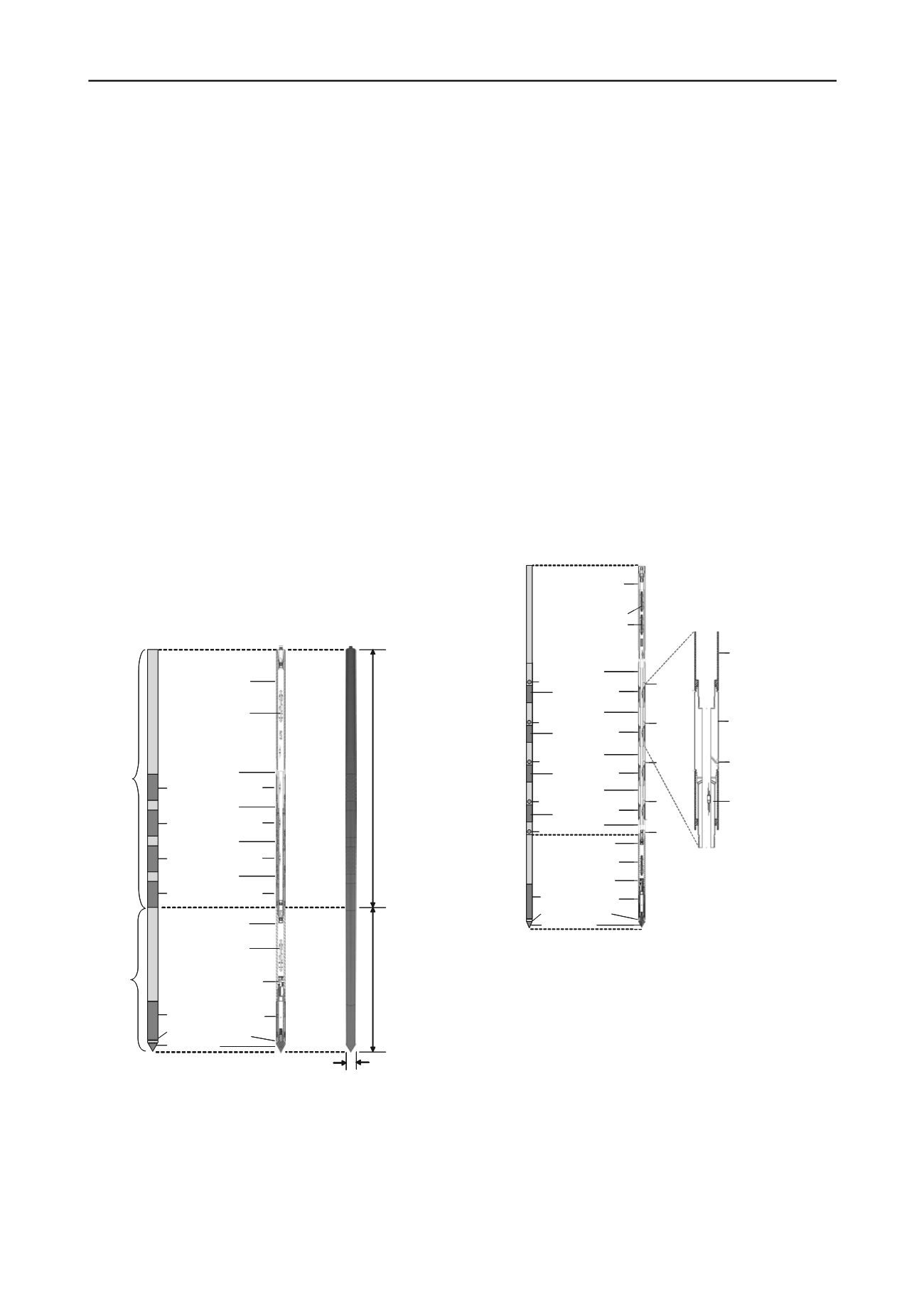

2.2 Second Generation: Multi-sleeve Piezo-Friction

Attachment (MPFA).

The second generation of multiple

sensor devices offers the ability to directly measure the

interface response over a range of counterface profiles,

while simultaneously measuring the excess pore water

pressure ahead of and after each friction sleeve as the device

is advanced into the subsurface. This is achieved by means

of its four independent load cells attached to the textured

sleeves and five independent dynamic pore pressure sensors.

Conventional 15 cm

2

CPT Module

Multi-Friction Sleeve

Penetrometer Attachment

q

c

f

s

f

s

#1

u

2

f

s

#2

f

s

#3

f

s

#4

Attachment

Digital

Housing

Attachment

Digital

Board

Digital

Housing

Digital

Board

Dual Axis

Inclinometer

Friction Sleeve

Tip

Pore Pressure

61 cm

109 cm

Friction Sleeve

Friction Sleeve

Friction Sleeve

Friction Sleeve

Mandrel

Mandrel

Mandrel

Mandrel

4.37 cm

Figure 1. Schematic of the multi-sleeve friction penetrometer along

with a standard CPT module.

The coupling of axial load and pore pressure sensors gives

the MPFA the ability to provide a direct measure of pore

water pressure generation due to shearing against surfaces of

different roughnesses. Several advantages offered by the

MPFA are the ability to consider the measured interface

response data within an effective stress framework which is

useful for applications such as liquefaction as well as

strength degradation, flow and consolidation characteristics

along the penetrometer’s shaft, more detailed data for

improved stratigraphy profiling, and the ability to

distinguish between drained, undrained and partially drained

conditions at the various sensor locations (Hebeler, 2005).

Figure 2 shows a schematic of the MPFA. Examples of the

unique insights resulting from the multi-sleeve sensor

technology include in-situ determination of the relationship

between interface friction and sleeve surface roughness

(Figure 3) and soil classification using interface behavior

(Figure 4).

3 PROPOSED SITE CHARACTERIZATION TOOL

3.1. Third Generation: Multi-sleeve Piezo-Friction-Torsion

Attachment (MPFTA).

The third generation of multi-sensor

devices being developed at the Georgia Institute of

Technology incorporates both axial and torsional shear as

well as pore pressure sensing capabilities.

f

s

f

a1

u

2

f

a2

f

a3

f

a4

Attachment

Digital

Housing

Digital Housing

u

a1

u

a0

u

a4

u

a3

u

a2

q

c

Friction Sleeve

Pore Pressure

Tip Load

Dual Axis

Inclinometer

Digital

Board

Attachment

Digital

Boards

Friction

Sleeve

Friction

Sleeve

Friction

Sleeve

Friction

Sleeve

Mandrel

Mandrel

Mandrel

Mandrel

Mandrel

Piezo

Sensor

Piezo

Sensor

Piezo

Sensor

Piezo

Sensor

Piezo

Sensor

Attachment

Sleeve

Mandrel

Replaceable

Attachment

Friction

Sleeve

Attachment

Individual

Load Cell

Attachment

Individual

Piezo Sensor

(0.67)

(0.81)

(0.88)

(1.07)

(1.14)

(1.33)

(1.40)

(1.59)

(1.66)

(a) (b)

Figure 2. Schematic of the multi-piezo-sleeve friction penetrometer

along with a standard CPT module (a) schematic - brackets indicate

sensor offset from tip in meters and (b) piezo friction sleeve

mandrel design detail.

Its dimensions and external characteristics, with and without

pore pressure sensing capabilities, are similar to the MFA

and MPFA shown in Figures 1 and 2, respectively. However,

the new concept incorporated into the device consists of a

dual load-torsion cell being installed in each sleeve module